Cut Edge Effects on Core Loss for Lamination Steels

Lamination steel is cut to the final shape by manufacturing process such as punching and laser cutting, which deteriorates the magnetic properties of the material. This is because the plastic deformation and residual stress near the cut edge cause core loss increase in the deformation region. These losses should be taken into account for the accurate prediction of core losses.

Cut-Edge Loss Model

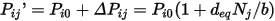

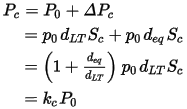

Assume core loss per unit volume without considering cut-edge effects is p0.

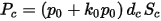

If the cut-edge deformation depth is dc, the cut-edge area is Sc, and the core loss increasing factor is k0, the core loss considering cut-edge effects will be

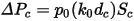

Thus, the loss increase due to cut-edge effects is

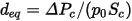

Because parameters dc and k0 cannot normally be derived individually, an equivalent cut-edge depth is introduced:

such that deq can be identified by

Parameter deq derivation

Based on the measurement of core loss of lamination sheets with variable width to consider the cut-edge effects, manufacturers can use single sheet testing method to measure the impact of cut-edges on core loss. The steps for deriving the parameter deq are as follows:

-

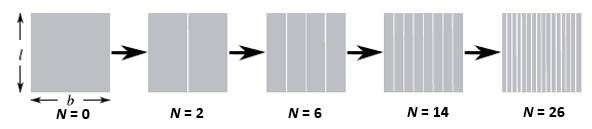

Cut lamination to N edges of different widths as shown below.

-

Measure the loss Pij with different width (j) under different magnetic polarization (i).

-

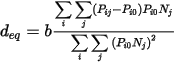

Derive the loss Pij’ using the cut-edge loss model to obtain one equation for every combination of i and j with parameter deq to be identified:

-

Find the error ε between derived and measured:

-

Derive parameter deq by minimizing the error:

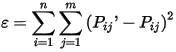

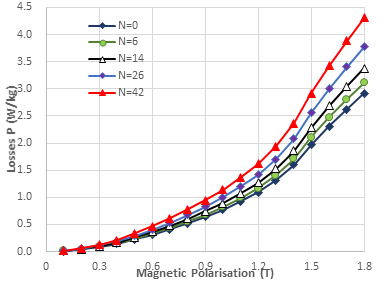

For example, the following shows the measured core loss varying with magnetic polarization for several values of the number of cut edges;

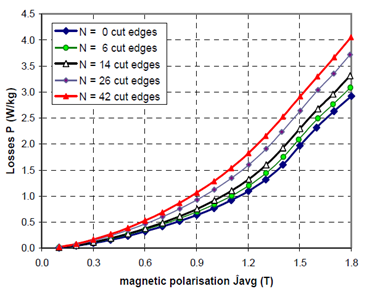

and the following shows the simulated core loss varying with magnetic polarization for several values of the number of cut edges

Maxwell Implementation of Cut Edge Effects

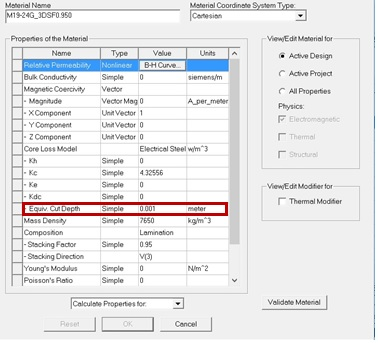

Maxwell uses the parameter deq described above as an additional input material property, Equiv. Cut Depth.

To implement cut edge effects, the Maxwell solver:

-

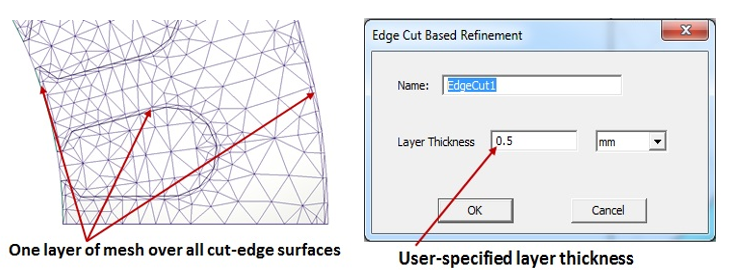

Constructs one layer of mesh over all cut-edge surfaces with user-specified layer thickness dLT

-

The solver then computes core loss considering cut-edge effects Pc on all elements inside the layer:

Additional Considerations

It is not necessary for the layer thickness dLT to be equal to the equivalent cut-edge depth deq since the above equation is able to ensure the derived core loss increase matches the measurements.

To take into account the cut-edge effects in core loss computation, the following three conditions must be fulfilled at the same time:

-

The Edge Cut Based mesh operation must be specified.

-

The Composition property for the assigned material must be set to Lamination.

-

The Equiv. Cut Depth material property must be set to a value greater than zero (default is 1 mm).