In the past, tolerance was just criterion to judge the quality of the gear. But now this tolerance is used not only for judging the quality but also as one of the main specifications. Tolerance is therefore used as one of the parameters to calculate the actual (generating) profile shift coefficients for adjusting the tooth thickness. This function supports External Gear Set, Internal Gear Set - Involute, Single Pinion Planetary Gear Set, and Cross Helical Gear Set.

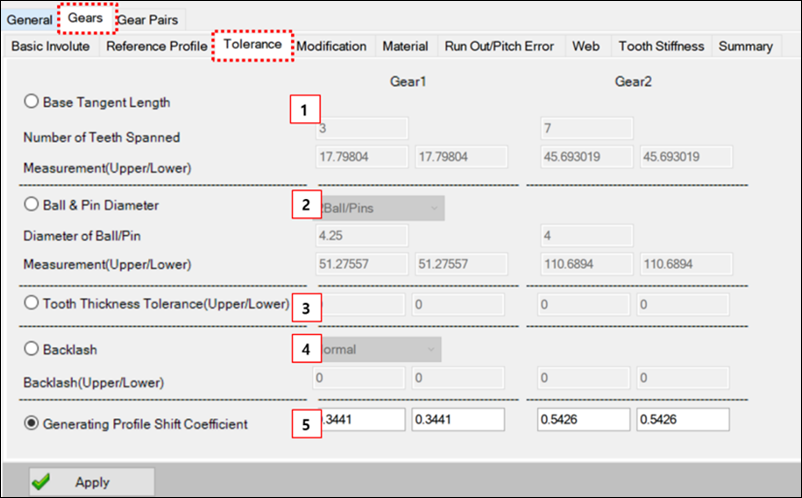

Figure 14.143: Parameters in the Tolerance tab

| Parameter | Description |

Dimension (Range) |

| 1. Base Tangent Length | Select this option when you have the tangent length and number of teeth spanned for the base tangent method. Enter the Number of Teeth Spanned by the base tangent and the Upper and Lower range limits for the tangent measurement. | Length |

| 2. Ball & Pin Diameter | Select this option when you have the specification for an over pin/ball measurement. Enter the Diameter of Ball/Pin used and the Upper and Lower range limits for the external measurement. | Length |

| 3. Tooth Thickness Tolerance | Select this option when you have a tolerance range of the tooth thickness directly. Specify Upper and Lower range limits for this value. | Length |

| 4. Backlash | Select this option when you have the Backlash value. Specify Upper and Lower range limits for this value. | Length |

| 5. Generating Profile Shift Coefficient | Select this option when you have a direct value for the Generating Profile Shift Coefficient. | N/A |

For all of the above measurements, the Upper and Lower values can be the same if there is no variance.