Tooth load distribution enables you to analyze gear meshing load-distribution at the contact point using a color map. The Tooth Contact Deformation (TCD) graph is useful to analyze deformation at the gear mesh contact point and the Tooth Contact Pressure (TCP) graph allows you to analyze the contact force. Based on the gearset, the tooth surface of the first gear is the base geometry, the tooth surface of the second gear is the action geometry, and TCP/TCD is always drawn based on the second gear.

TCP/TCD is the accumulated colormap (see Figure 4.52: TCP/TCD color map) of the contact force from start to end of single gear contact. If the involute point of gear contact has not changed by the next simulation step, the contact force is added to the previous result. The observation time for TCP/TCD can be set in Tooth Pressure in the Preprocessor Assembly Manager.

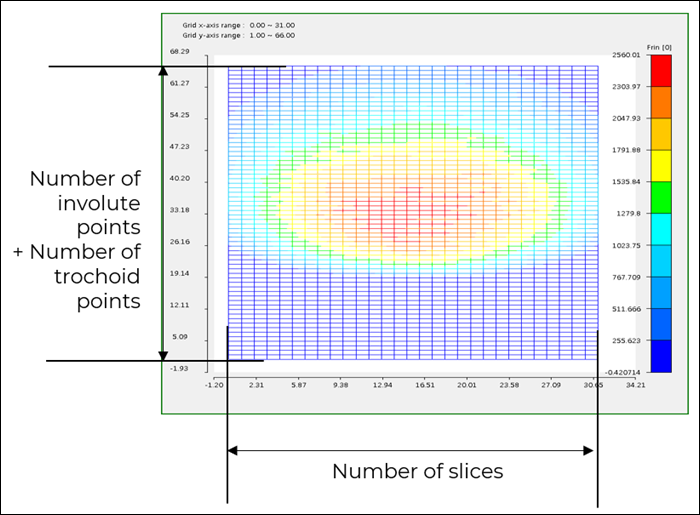

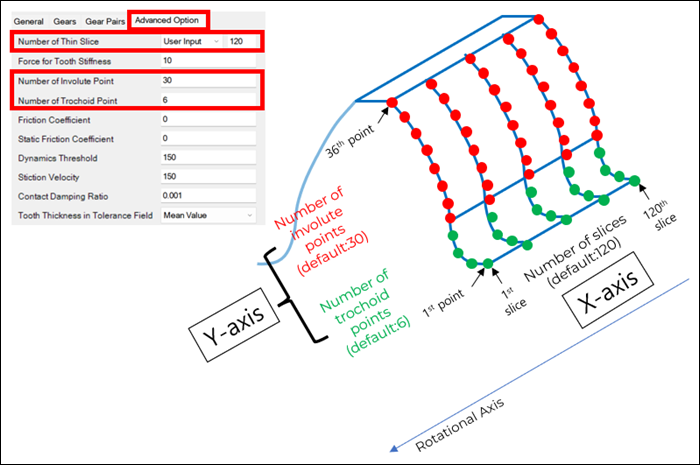

The axes of the color map are as defined in the Preprocessor: the x-axis is number of slices and the y-axis is the sum of number of involute points and the number of trochoid points (see Figure 4.53: Sum of involute and trochoid points).

A test verification of load distribution during tooth contact was completed as shown in Figure 4.54: Test verification of load distribution. This test verification was conducted by applying loads under various conditions to the same gear, painting the tooth surfaces of the gear, and confirming the paint peeling off at the area where the teeth engage under operating conditions.

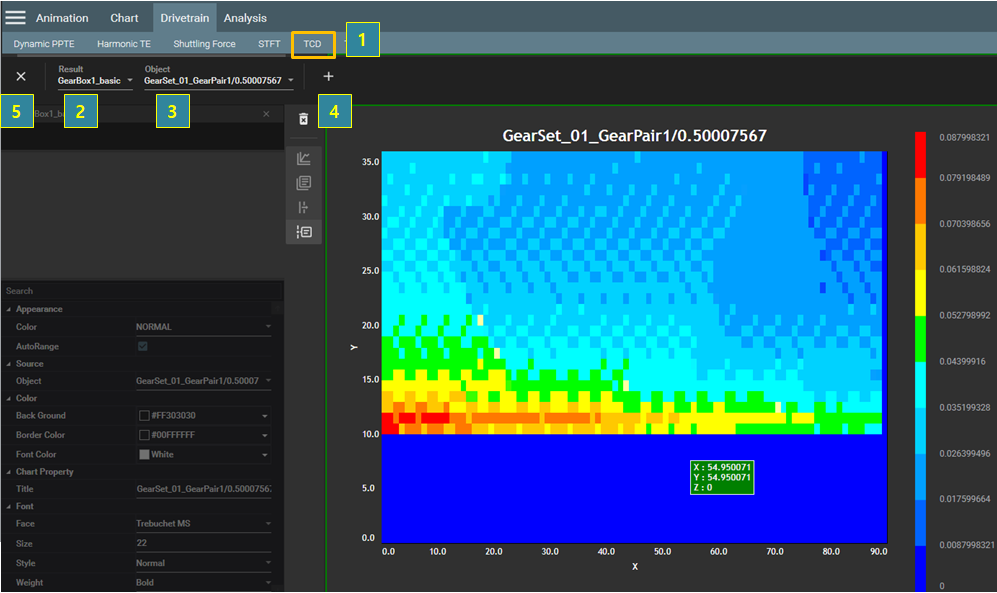

TCP/TCD can be performed using the following steps (see Figure 4.56: TCP/TCD):

Figure 4.55: Steps for TCP/TCD

| Step | Description |

| 1 | Click in the menu bar. |

| 2 | Under Result, select the DFR filename. |

| 3 | Under Object, select the gear set. |

| 4 | Click the  button to create the graph. button to create the graph. |

| 5 | Click the  button to close the operation. button to close the operation. |

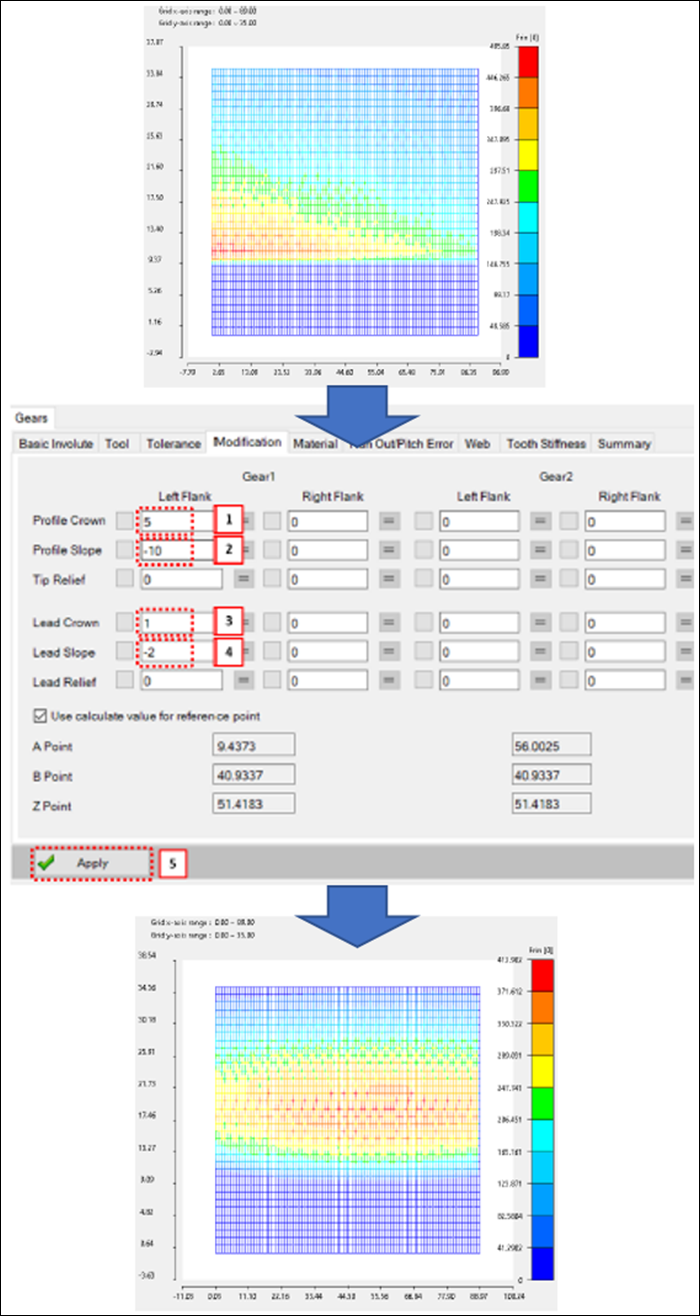

TCP/TCD can be used as a simple result, but to use it more effectively it is better to use the TCP/TCD result to modify tooth parameters. To make the contact between gear tooth surfaces uniform and effective, it is best to distribute the contact area evenly based on the center of the gear tooth surfaces. However, since this varies depending on load or driving conditions, it is necessary to make a judgement accordingly.