VM323

VM323

Total Strains of a Bar With Combined Plasticity and Creep

Overview

| Reference: | Duxbury, P.G., Crook, T., & Lyons, P. (1994). A consistent formulation for the integration of combined plasticity and creep. International Journal for Numerical Methods in Engineering, 37, 1277-1295. |

| Analysis Type(s): | Static (ANTYPE,0) |

| Element Type(s): |

3-D Structural Solid Elements (SOLID185) |

| Input Listing: | vm323.dat |

Test Case

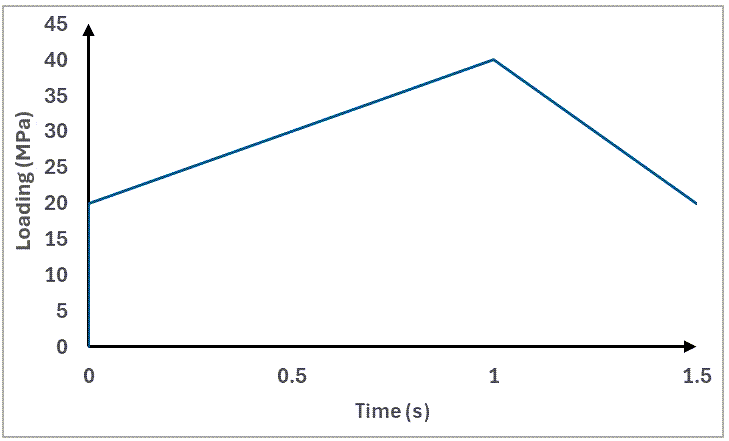

A bar is modeled using BISO material and a time-hardening creep model. Uniaxial pressure loading is applied in the vertical direction. The loading history is composed of three steps as shown in Figure 591. Loading is ramped to 20 MPa in 1e-8 s in the first step. It is then ramped to 40 MPa in 1 s in the second step. Finally, loading is ramped down to 20 MPa in 0.5 s in the last step. The total strain history is obtained and compared against the reference solution.

| Material Properties | Geometric Properties | Loading | ||||||

|---|---|---|---|---|---|---|---|---|

|

E = 20,000 MPa µ = 0.3

BISO model:

Time hardening creep model:

|

Bar length L = 10 mm Cross area A =1 mm | Pressure loading, see Figure 591: Loading History . |

Analysis Assumptions and Modeling Notes

The problem is solved using 3D SOLID185 elements with the reduced integration option and mixed u-P formulation. Plasticity and creep are defined by TB,PLAS, and TB,CREEP, respectively. The bar is subjected to different pressure loadings in three steps. The effect of creep strain rate is turned off in the first step but turned on in the second and third steps by RATE, ON. The history of total strains in the loading direction is acquired in both /POST1 and /POST26.

Results Comparison

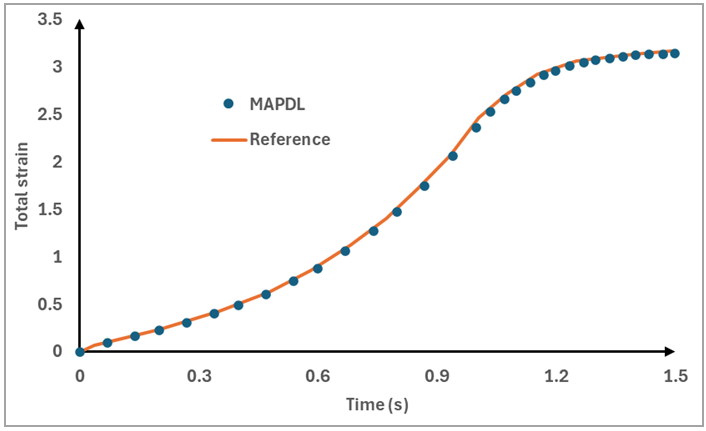

The history of the total strains of the bar is shown in Figure 592.

The total final strain calculated by Mechanical APDL is compared to the reference:

| Total Final Strain | |||

|---|---|---|---|

| Time | Target | Mechanical APDL | Ratio |

| 1.5 s | 3.167 | 3.137 | 0.990 |