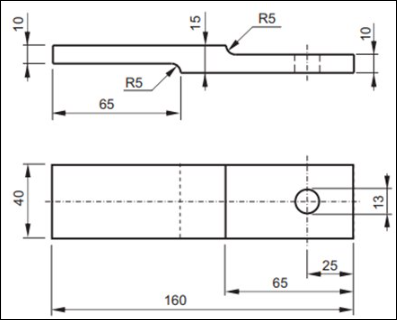

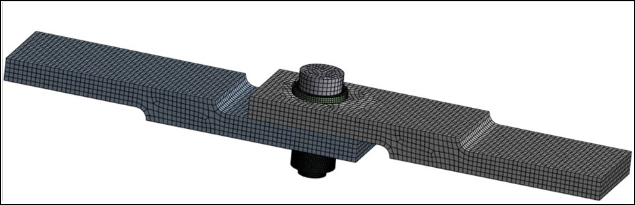

SOLID185 elements are used to mesh the two plates, the bolt, the nut, and the washers as shown in Figure 71.5: Discretized Assembly of the Lap Joint. The global default element size is 2.00 mm. A local refinement element size was chosen to mesh the solid model in the Mechanical application for the washers (1.00 mm) and for the threaded parts (0.40 mm). For the simplified bolt thread model, a fine mesh is needed for better local accuracy (one fourth of the pitch).

A refined mesh size of 0.40 mm is used for the threaded parts only. Fine and coarse meshed parts of the bolt are attached with bonded contact. Frictional contact (µ = 0.20) is used for all wearing surfaces' connections: threaded connection between the bolt and the nut, the nut and the washer, the washer and the plate, and the bolt head and the washer with contact elements (CONTA174) and target elements (TARGE170). The model uses symmetric contact to simulate wear on different mating parts except for the simplified bolt thread model. Contact and target elements are defined on both surfaces as wear can be modeled only on surfaces that have contact elements.

The CONTA174 elements with the following settings are used:

Method of contact detection point: standard projection method surface (KEYOPT(4) = 3).

Contact formulation: Augmented Lagrangian formulation (KEYOPT(2) = 0).

Contact stiffness is updated at each iteration (KEYOPT(10) = 0).

Wear is simulated by defining a wear model (TB,WEAR) and assigning it to the contact elements. A generalized form of the Archard wear model is used. Contact elements are defined on the surfaces undergoing wear. A wear model is then associated with those contact elements via a TB,WEAR material definition. The following command defines the Archard wear model:

TB,WEAR,CID,,,ARCD

where CID is the material ID associated with the contact elements. Same wear properties are used for all wearing surfaces:

ksteel = 1e-7 timeend = 6.00*(1/fapp) timebeg = 1+.01*(1/fapp) TB,WEAR,CID,,,ARCD ! Mat # = material for wear of contact element TBFIELD,TIME,0 ! Time at the beginning of load step 1 TBDATA,1,0.0,1,1,1,1 ! C1 = 0 results in no wear for load step 1 TBFIELD,TIME,1 ! Time at the end of load step 1 TBDATA,1,0.0,1,1,1,1 ! C1 = 0 results in no wear for load step 1 TBFIELD,TIME,timebeg ! Time at the beginning of load step 2 TBDATA,1,ksteel,1,1,1,1 ! Value of wear coefficient resulting in initiation of wear TBFIELD,TIME,timeend ! Time at the end of load step 2 TBDATA,1,ksteel,1,1,1,1 ! Wear coefficient kept constant during load step 2 TB,WEAR,TID,,,ARCD ! Mat # = material for wear of target element TBFIELD,TIME,0 ! Time at the beginning of load step 1 TBDATA,1,0.0,1,1,1,1 ! C1 = 0 results in no wear for load step 1 TBFIELD,TIME,1 ! Time at the end of load step 1 TBDATA,1,0.0,1,1,1,1 ! C1 = 0 results in no wear for load step 1 TBFIELD,TIME,timbeg ! Time at the beginning of load step 2 TBDATA,1,ksteel,1,1,1,1 ! Value of wear coefficient resulting in initiation of wear TBFIELD,TIME,timeend ! Time at the end of load step 2 TBDATA,1,ksteel,1,1,1,1 ! Wear coefficient kept constant during load step 2

Adaptive wear scaling is used to speed up the wear process with the following scaling parameters for each contact pair:

TB,WEAR,CID,,,AUTS ! Adaptive wear scaling for the contact element TBDATA,1,0.1,1000 ! Wear scaling parameters TB,WEAR,TID,,,AUTS ! Adaptive wear scaling for the target element TBDATA,1,0.1,1000 ! Wear scaling parameters

The first parameter (0.10) represents the safety factor, that controls wear depth in terms of the penetration. The second parameter (1000) specifies the upper limit of the wear scale factor (See Automatic Scaling of Wear Increment). The maximum wear scale factor is chosen as the ratio of estimated life cycles to simulation cycles. A large value of maximum wear scale factor may lead to inaccuracy or even numerical instability. The specified maximum wear scale factor should be small enough to have no effect on the simulation results.

Modeling wear involves repositioning contact surface nodes to simulate the material removal process. As a result, the element quality of the solid elements underlying the contact elements can quickly deteriorate. Nonlinear mesh adaptivity is used to resolve the mesh distortion issue. A component named conwearel is created, and the following command triggers mesh adaptivity:

allsel,all esel,s,ename,,170,174,4 cm,conwearel,elem nlad,conwearel,add,contact,wear,0.30 !morph after 30% is lost in wear nlad,conwearel,on,all,all,1,,6 nlad,conwearel,list,all,all

In this case, adaptivity occurs whenever wear at any contact point exceeds 30% of the average height of the solid element underlying the contact element. Each time the criterion is reached, the analysis is stopped, the mesh quality is improved by morphing the mesh, history-dependent variables and boundary conditions are mapped, and the analysis is restarted with an improved mesh. This process is done automatically, and wear variables again start from zero.