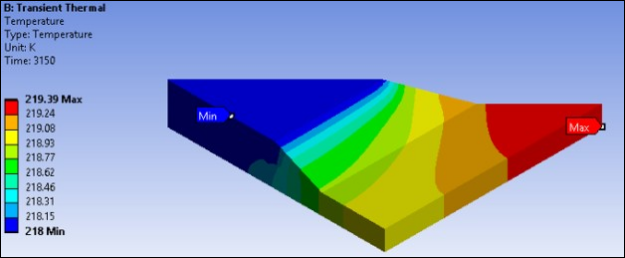

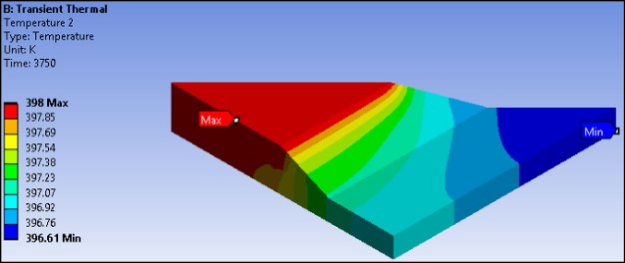

The following figure shows the temperature distribution at the end of the 12th and 14th load steps.

Temperature on the chip is reduced from 398 K to 218 K in the 12th load step and increased from 218 K to 398 K in the 14th load step.

The temperature distribution is nearly uniform in all load steps, due to assumed perfect thermal contact between parts of the flip chip and a high thermal contact conductance value. These results are used in the structural analysis as thermal loading.

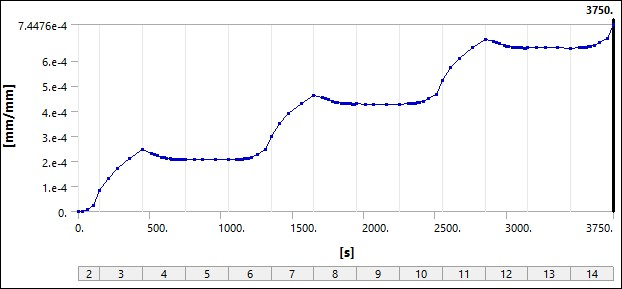

The reference structural analysis [3] results using the generalized Garofalo creep model constants are compared to the structural analysis results with creep curve-fitting constants.

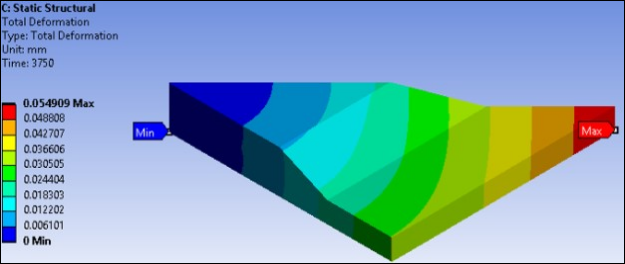

Figure 35.13: USUM Results from Creep Curve Fitting Constants and Reference Constants at the End of 14th Load Step (3750 Seconds)

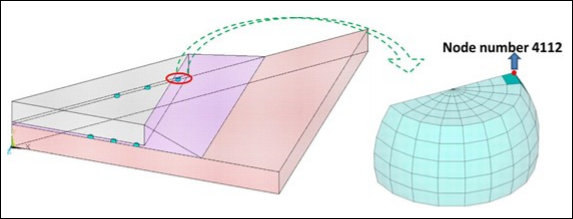

All time-history results are plotted for solder element results at node 4112, positioned at the end of farthest solder bead from the center near the chip, as shown in the following figure.

Due to unavailable thermal contact conductance and plasticity behavior used in the reference analysis, the following assumptions apply to this problem:

Perfect thermal contact between parts of the flip chip.

Elastic and perfectly plastic behavior with isotropic hardening in the structural analysis.

The results based on the curve-fitting creep constants are therefore compared to another analysis using the reference creep constants and run with the same assumptions, as shown in this figure:

Observe the increase in creep strain with cyclic load steps.