This section discusses the results for both models analyzed in this problem:

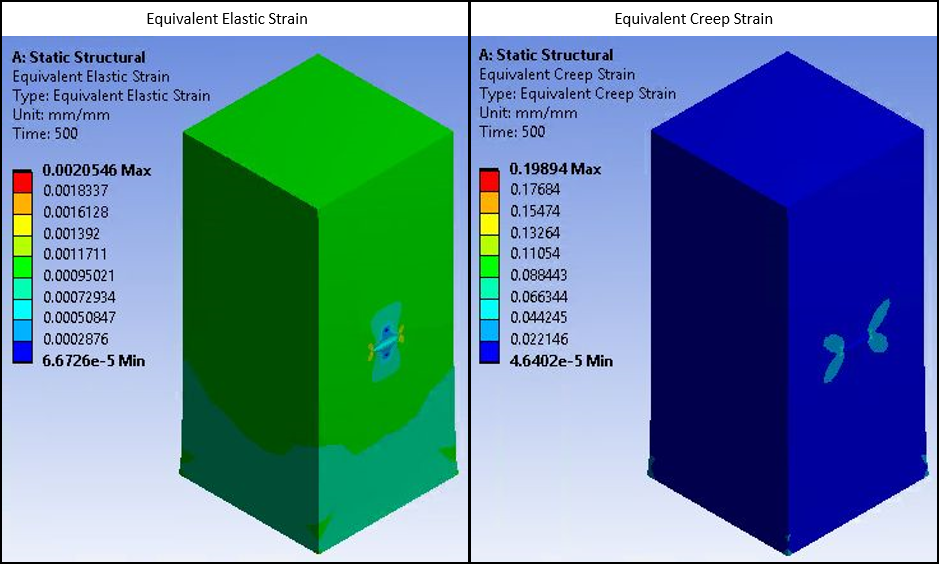

The following figures show the equivalent elastic strain and equivalent creep strain.

The creep strain is approximately 100 times larger than the elastic strain in the secondary creep stage, which dominates the entire specimen at the end of the simulation.

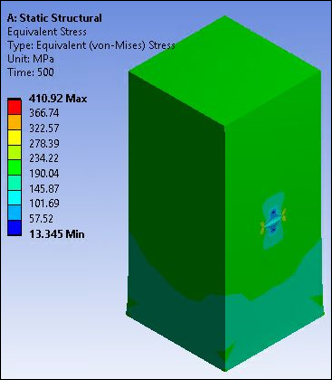

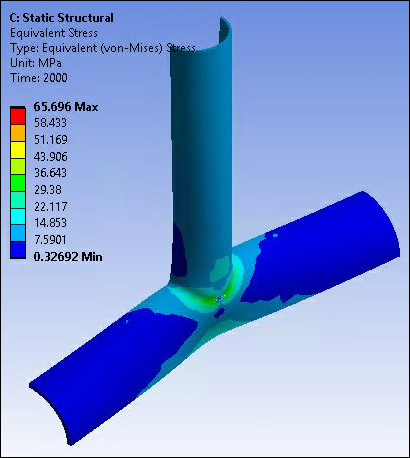

The maximum equivalent Stress occurs at the crack tip as seen in the following figure.

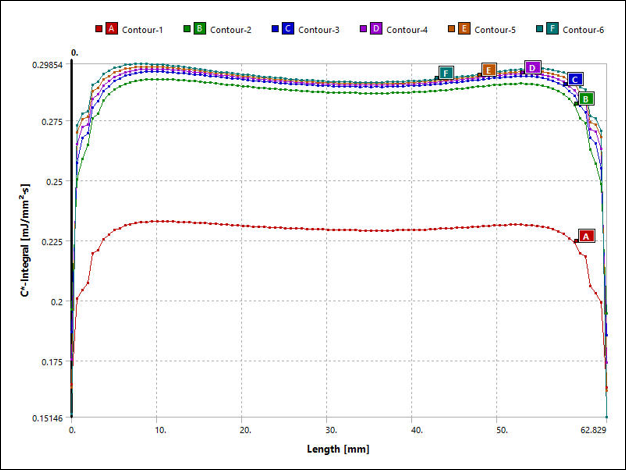

The following figure shows the C*-integral along the crack front for different contours. Path-independence appears after contour 2.

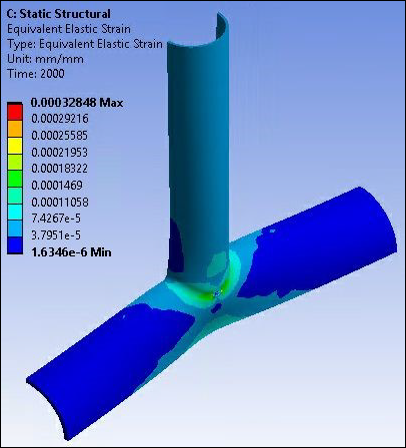

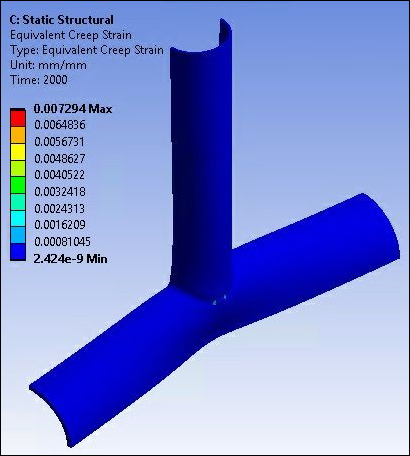

The following figures show the equivalent elastic strain, equivalent creep strain, and equivalent stress of the X-joint pipe with the warped flaw at the welded joint.

The creep strain is approximately 22 times larger than the elastic strain in the secondary creep stage, which dominates the local region of specimen at the end of the simulation.

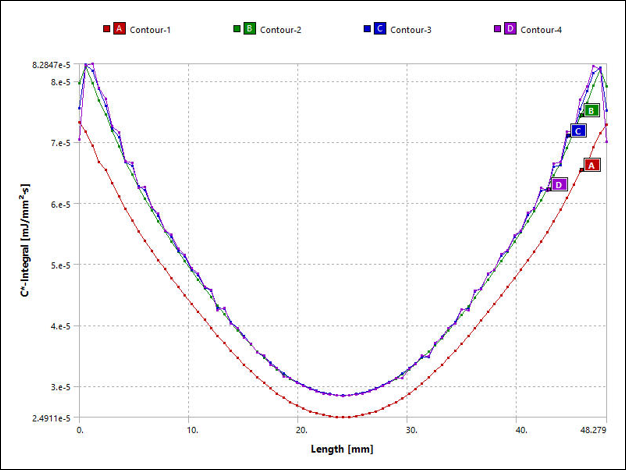

The following figure shows the C*-integral values along the crack front, which gradually becomes path-independent after contour 2.