VM-WB-MECH-092

VM-WB-MECH-092

Convection Treatment Problem for a Hollow Cylinder with

Fluid Flow

Overview

| Reference: |

Arpaci, V. S., Selamet, A., & Kao, S. H. (2000). Introduction to heat transfer (pp. 90-100). | |||

| Solver(s): | Ansys Mechanical | |||

| Analysis Type(s): | Static Structural | |||

| Element Type(s): |

|

Test Case

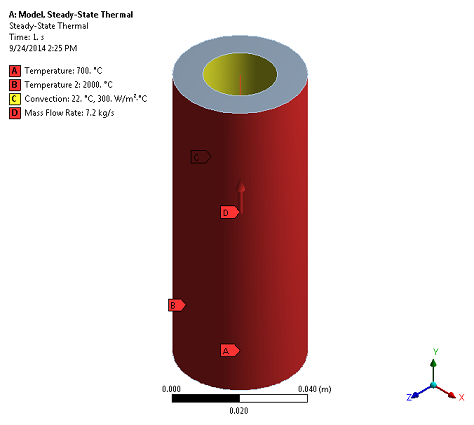

A hollow cylinder is modeled with an inner radius of 0.01105 m, an outer radius of 0.02 m, and a length of 0.1 m. Fluid is made to flow through the cylinder to simulate the convection problem. Surface effect elements with film coefficients are used in between the fluid and cylinder to include the convection loads. The inlet temperature of the fluid, mass flow rate of the fluid, and the bulk temperature at the outer cylinder surface are defined. A static analysis is performed on the model to determine the nodal temperature of the fluid elements.

This problem is also presented in VM271

in the Mechanical APDL Verification Manual.

| Material Properties | Geometric Properties | Loading | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

|

|

Analysis Assumptions and Modeling Notes

The line body model type is set to thermal fluid and the discretization type is set to upwind/exponential in a 3-D steady state thermal analysis.

The existing convection is scoped to the inner face of the cylinder and is modified to consider fluid flow with fluid flow edge(s) of line bodies.

The mass flow rate is applied using line body edge.

The problem is solved using MKS as the unit system. Results are evaluated at different locations on a line body using nodal named selections.