VM-GEOM-SCMD-001

VM-GEOM-SCMD-001

Evaluation of Equivalent Orthotropic Material Properties for Multi-Layered Laminated

Structures

Overview

| Reference | Millithaler, P., Sadoulet-Reboul M., Ousse, E., Dupont, J.-B., & Bouhaddi, N.

(2014). Equivalent Orthotropic Material Properties for Stators of Electric Cars. In

Topping, B.H.V. & Iványi P. (Eds.), Proceedings of the Twelfth

International Conference on Computational Structures Technology (DOI:

10.4203/ccp.106.201). Stirlingshire, Scottland: Civil-Comp Press. See also Researchgate.net. |

| Feature | User-Defined RVE |

Test Case

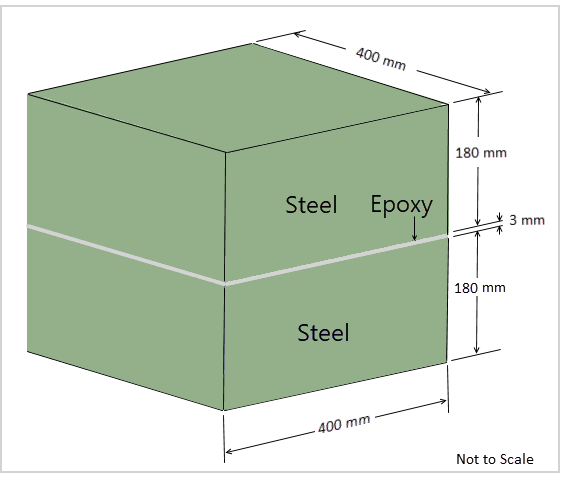

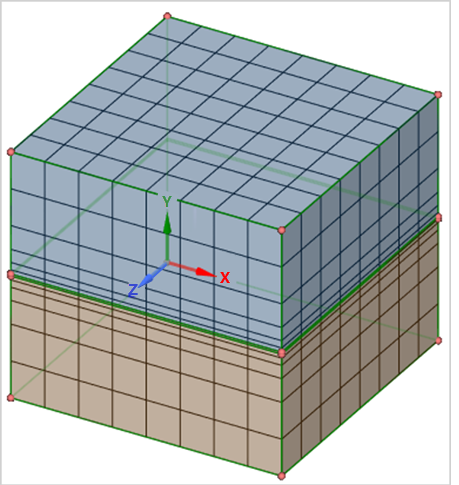

Create a user-defined RVE (representative volume element) in Material Designer as shown in Figure 257: Test Case Model. The constituent materials are two steel layers with a layer of epoxy between them. Using the information in the table below, assign dimensions and material properties to each layer. Run an analysis on the RVE and generate calculated properties for the homogenized laminate. Compare the results to those given in the reference above (Milithaler et al., 2014).

Note: The Material Designer User's Guide provides a detailed treatment of this test case in the User Defined RVE Tutorial. There you will find a step-by-step guide to setting up the model as well as a link for downloading the project file.

| Geometric Properties | Material Properties | ||

|

Epoxy Block: 3 mm x 400 mm x 400 mm Two Steel Blocks: 180 mm x 400 mm x 400 mm | Steel | Epoxy | |

| Young's Modulus [GPa] | 207 | 3.0 | |

| Poisson's Ratio | 0.25 | 0.37 | |