Start Ansys Polymat by typing polymat. Then follow the

procedure below to perform the fitting for the data presented in Experimental Data.

![]() Select Fluid Model

Select Fluid Model

Choose a Generalized Newtonian non-isothermal model.

Generalized Newtonian non-isothermal model

Generalized Newtonian non-isothermal model

Return to the top-level menu.

![]() Material Data

Material Data

Specify the shear-rate dependence.

Shear-rate dependence of viscosity

Shear-rate dependence of viscosity

Select the Carreau-Yasuda law.

Carreau-Yasuda law

Carreau-Yasuda law

Return to the Material Data menu.

Specify the temperature dependence.

Temperature dependence of viscosity

Temperature dependence of viscosity

Select the Arrhenius shear stress law.

Arrhenius shear stress law

Arrhenius shear stress law

Enable the fixing of parameters.

Click the button at the top of the Ansys Polymat menu.

Click to confirm that fixing is enabled.

Fix the value of

to be 240.

Specify

.

Modify talfa

Modify talfa

Specify that

is fixed.

talfa is a fixed value

talfa is a fixed value

Return to the Arrhenius shear stress law menu.

Fix the value of

to be

.

Specify

.

Modify t0

Modify t0

Specify that

is fixed.

t0 is a fixed value

t0 is a fixed value

Return to the Arrhenius shear stress law menu.

Disable the fixing of parameters.

Click the button at the top of the Ansys Polymat menu.

Click to confirm that fixing is disabled.

Return to the top-level Ansys Polymat menu.

Enter the Automatic Fitting menu.

Automatic fitting

Automatic fitting

Enter the List of Experimental Curves menu.

Add experimental curves

Add experimental curves

Add the first experimental curve (

temp_200.crv). Add a new curve

Add a new curve

Select the curve named temp_200.crv.

Enter the name of the curve file

Enter the name of the curve file

Set the reference temperature to

200. Modify the temperature

Modify the temperature

Return to the List of Experimental Curves menu.

Add the second experimental curve (

temp_220.crv). Add a new curve

Add a new curve

Select the curve named temp_220.crv.

Enter the name of the curve file

Enter the name of the curve file

Set the reference temperature to

220. Modify the temperature

Modify the temperature

Return to the List of Experimental Curves menu.

Repeat to add the third and fourth experimental curves (

temp_240.crvandtemp_260.crv) and set the appropriate reference temperatures.Return to the Automatic Fitting menu.

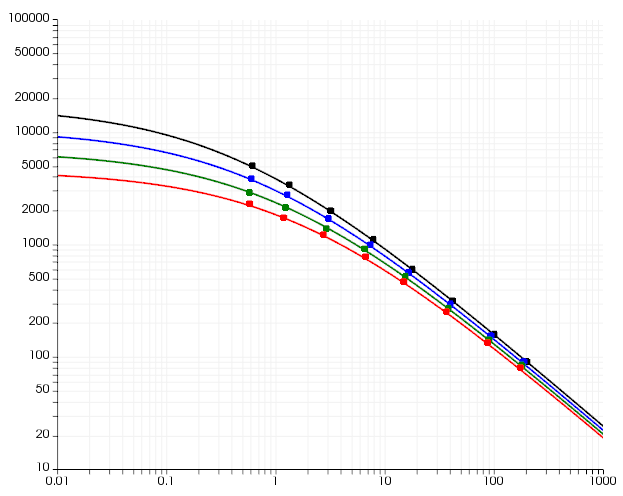

Plot the four experimental data curves.

Draw experimental curves

Draw experimental curves

Specify a name for the material data file (for example,

example1.mat). Enter the name of the result file

Enter the name of the result file

Start the fitting calculation.

Run fitting

Run fitting

The results of the fitting calculation are as follows:

RESULTS Carreau-Yasuda law f(g) = facinf + (fac-facinf) * [1+(tnat*g)**expoa]**((expo-1)/expoa) fac = 0.6793715E+04 [auto] tnat = 0.9776775E+00 [auto] expo = 0.1625742E+00 [auto] facinf = 0.9628369E-03 [auto] expoa = 0.5421551E+00 [auto] Arrhenius shear stress law h(t) = exp( alfa / (t-t0) - alfa / (talfa-t0) ) alfa = 0.5559034E+04 [auto] talfa = 0.2400000E+03 [fixed] t0 = -0.2731500E+03 [fixed]

The computed and experimental curves are shown in Figure 10.1: Plot of Computed and Experimental Curves.