Material models in LS-DYNA use history variables that are specific to the material model. For most materials, six variables are reserved for the Cauchy stress components and one for the effective plastic strain, but some models have many more. The extra history variables may include properties like strain energy density and strain rate, and may also include information like material direction cosines and scale factors.

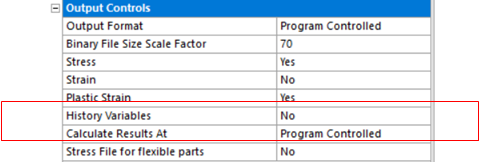

The output of these extra history variables is defined in the Output Controls section of the Analysis Settings Details.

If you set History Variables to Yes (the default is No), LS-DYNA automatically sets the number of history variables for shell and solid elements in the model. It calculates the value depending on the materials and on the type of bodies present in the model.

Depending on the material assigned to your body, you will have history variables available in the Solution Worksheet and can evaluate them as a User Defined Result.

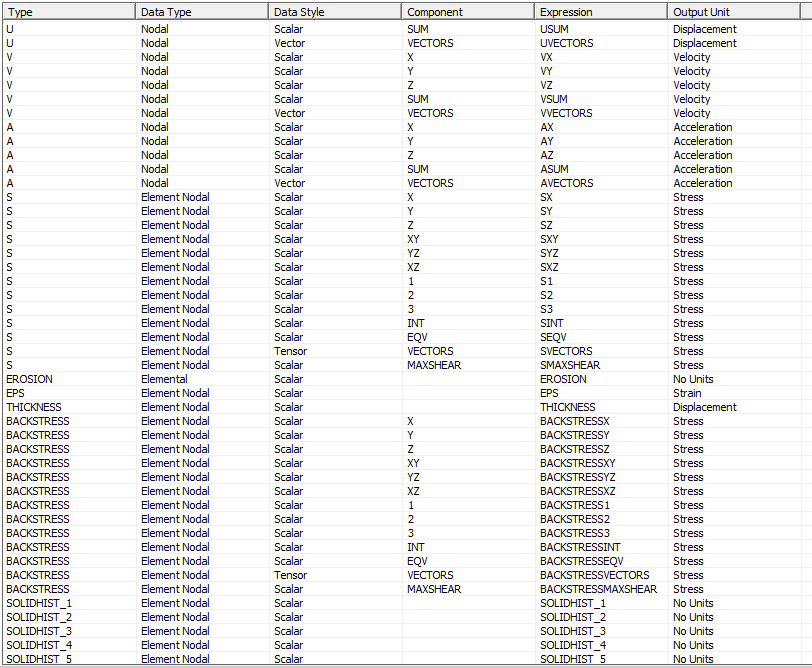

The number of extra history variables is dependent on the material model used. The following table shows the history variables for the equation of state/material combinations supported by LS-DYNA.

| Materials Supported in LSDYNA | Corresponding Mat Number | Var No. | Shells (and Thick Shells Types 1,2,6) | Var No. | Solids (and Thick Shell Types 3,5,6) |

|---|---|---|---|---|---|

| *MAT_3-PARAMETER_BARLAT | *MAT_036 | ||||

| 1 | reverse of old yield stress | ||||

| 3 | cosine(alpha) | ||||

| 4 | - sine(alpha | ||||

| 6 | effective strain rate | ||||

| 7 | current yield stress | ||||

| 8 | current hardening slope | ||||

| 9 | back stress component alpha_11 | ||||

| 10 | back stress component alpha_22 | ||||

| 11 | back stress component alpha_12 | ||||

| *MAT_BARLAT_ANISOTROPIC_PLASTICITY | *MAT_033 | NA | |||

| *MAT_ADD_EROSION | NA | NA | |||

| *MAT_ARRUDA_BOYCE_RUBBER | *MAT_127 | NA | |||

| *MAT_BLATZ-KO_RUBBER | *MAT_007 | NA | 1..9 | deformation gradient | |

| *MAT_ELASTIC | *MAT_001 | eqp | volumetric strain | eqp | volumetric strain |

| *MAT_ENHANCED_COMPOSITE_DAMAGE | *MAT_054-055 | ||||

| (MAT_054) | 1 | flag for longitudinal tensile failure mode | |||

| (MAT_054) | 2 | flag for longitudinal compressive failure mode | |||

| (MAT_054) | 3 | flag for transverse tensile failure mode | |||

| (MAT_054) | 4 | flag for transverse compressive failure | |||

| (MAT_054) | 5 | mode | |||

| (MAT_054) | 6 | total failure | |||

| (MAT_054) | 8 | damage parameter (SOFT) | |||

| (MAT_054) | 9 | cosine(alpha) | |||

| (MAT_054) | 10 | - sine(alpha) | |||

| (MAT_054) | 11 | local strain a-direction | |||

| (MAT_054) | 12 | local strain b-direction | |||

| (MAT_054) | 16 |

local shear strain (ab-plane) transverse shear damage | |||

| *MAT_LAMINATED_COMPOSITE_FABRIC | *MAT_058 | ||||

| 1 | damage in longitudinal direction | ||||

| 2 | damage in transverse direction | ||||

| 3 | damage in shear | ||||

| 6 | cosine(alpha | ||||

| 7 | -sine(alpha | ||||

| 8 | total failure flag (1=not failed, 0=failed) | ||||

| 10 | local strain a-direction | ||||

| 11 | local strain b-direction | ||||

| 12 | local shear strain (ab-plane) | ||||

| 15 | effective strain | ||||

| 16 | local strain c-direction | ||||

| 17 | local transverse shear strain (bc-plane) | ||||

| 18 | local transverse shear strain (ca-plane) | ||||

| 19 | damage variable for transverse shear behavior | ||||

| 20 | strain-rate in a-direction | ||||

| 21 | strain-rate in b-direction | ||||

| 22 | strain-rate in ab-plane | ||||

| *MAT_FLD_TRANSVERSELY_ANISOTROPIC | *MAT_039 | NA | |||

| *MAT_HYPERELASTIC_RUBBER | *MAT_077_H | NA | |||

| *MAT_JOHNSON_COOK | *MAT_015 | ||||

| 1 | failure value | 5 | temperature change | ||

| 3 | current pressure cutoff | 6 | JC damage parameter | ||

| 4 | JC damage parameter | ||||

| 5 | temperature change | ||||

| 6 | JC failure strain | ||||

| *MAT_MODIFIED_PIECEWISE_LINEAR_PLASTICITY | *MAT_123 | ||||

| 1 | effective strain rate | 1 | effective strain rate | ||

| 6 | thinning strain | 7 | major principal strain | ||

| 7 | major in plane strain | ||||

| *MAT_OGDEN_RUBBER | *MAT_077_O | NA | |||

| *MAT_ORTHOTROPIC_ELASTIC, *MAT_ANISOTROPIC_ELASTIC | *MAT_002 | ||||

| eqp | stiffness component C11 | 1..9 | deformation gradient | ||

| 1 | stiffness component C12 | ||||

| 2 | stiffness component C13 | ||||

| 3 | stiffness component C14 | ||||

| 4 | stiffness component C22 | ||||

| 5 | stiffness component C23 | ||||

| 6 | stiffness component C24 | ||||

| 7 | stiffness component C33 | ||||

| 8 | stiffness component C34 | ||||

| 9 | stiffness component C44 | ||||

| 10 | stiffness component C55 | ||||

| 11 | stiffness component C56 | ||||

| 12 | stiffness component C66 | ||||

| *MAT_PIECEWISE_LINEAR_PLASTICITY | *MAT_024 | ||||

| 1 |

effective strain rate (VP=0); effective plastic strain rate (VP=1) | 1 |

effective strain rate (VP=0); effective plastic strain rate (VP=1) | ||

| 4 | current hardening slope | 4 | current hardening slope | ||

| 5 |

current yield stress Remark: 4 and 5 apply only to non-strain-rate option. | 5 |

current yield stress Remark: 4 and 5 apply only to non-strain-rate option. | ||

| *MAT_PLASTIC_KINEMATIC | *MAT_003 | ||||

| 1 | back stress component xx | 1 | back stress component xx | ||

| 2 | back stress component yy | 2 | back stress component yy | ||

| 3 | back stress component xy | 3 | back stress component xy | ||

| 4 | back stress component yz | 4 | back stress component yz | ||

| 5 | back stress component zx | 5 | back stress component zx | ||

| *MAT_POWER_LAW_PLASTICITY | *MAT_018 | NA | |||

| *MAT_RATE_SENSITIVE_POWERLAW_PLASTICITY | *MAT_064 | NA | |||

| *MAT_RIGID | *MAT_020 | NA | |||

| *MAT_SIMPLIFIED_JOHNSON_COOK | *MAT_098 | ||||

| 1 |

max(0,ln(normalized eff strain rate)) (VP=0) failure flag (VP=1) | ||||

| *MAT_SPRING_INELASTIC | *MAT_S08 | NA | |||

| *MAT_SPRING_NONLINEAR_ELASTIC | *MAT_S04 | NA | |||

| *MAT_TRANSVERSELY_ANISOTROPIC_ELASTIC_PLASTIC | *MAT_037 | ||||

| 2 | current hardening slope | ||||

| 3 | current yield stress | ||||

| *MAT_LOW_DENSITY_FOAM | *MAT_057 | NA |

The following table shows the history variables for equation of state/material combinations supported by LS-DYNA.

| Equation of State | Material | Var No. | Var Description |

|---|---|---|---|

| *EOS_JWL (EOS_002) | *MAT_HIGH_EXPLOSIVE_BURN (*MAT_008) | 1 | Internal Energy |

| 2 | Bulk Viscosity | ||

| 3 | Volume | ||

| 4 | Burn Fraction | ||

| 5 | Afterburn Energy |

Note: For User Defined Results with the Output Unit value of No Units, the unit system used is the one defined in the Unit System field in the Analysis Settings Solver Controls section. For User Defined Results with an Output Unit value other than No Units, the unit system used is the one defined in the Mechanical Home tab.