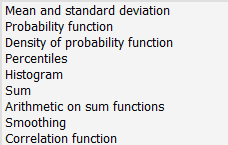

This section describes the following topics:

Analyzing the results provided by a simulation may be challenging, especially if the flow occurs in a complex geometry, if it is transient, or if we want to compare results obtained with similar setups. How can we render our analysis “objective”? In this chapter, we propose a set of tools to reach that goal, and more specifically, tools to quantify the various aspects of the mixing process.

The basic idea is the following: we release in the flow domain a large set of material points (also named massless or virtual particles) and compute their pathlines in the flow. Along these pathlines, we evaluate and store in files a set of relevant quantities (temperature, velocities, shear-rate, ..). Once this “tracking” task is completed for a large set of points, we perform a statistical analysis on these quantities: we cut these pathlines at various times (if the flow is transient) or by cutting planes (if the flow has inlet and outlet sections): each slice will thus contain a sample of values (E.G. all temperatures of pathlines crossed by plane z=3). For each sample, we can evaluate mean, standard deviation, histograms, etc., leading to a quantified and objective measurement of some characteristics of the flow (e.g. residence time distribution at the outlet section of the flow domain, time evolution of the axial distribution of points in an extruder, fraction of points experiencing a stress above a given threshold, ..).

In polymer blending, a minor component is generally present as drops (or filaments) in a continuous phase of a major component. Mixing is a process of deformation and rupture of the drops but also a process of distribution of those drops in the whole flow domain. Good mixing is characterized by small and identical drops distributed uniformly throughout all of flow domain.

Deformation of drops is promoted by the viscous stress exerted on the drops by the flow field and counteracted by the

interfacial stress

.

is the interfacial tension and R, the local radius. The capillary

number is useful to characterize mixing.

For a given pair of polymers, a critical Capillary number may be found. It corresponds to the situation where the viscous stress competes with the interfacial stress. The drop is extended and finally breaks up into smaller droplets. This process is called dispersive mixing. Note that an extensional flow field is more efficient for breaking up drops into droplets than a shear flow is.

If the capillary number is much higher than the critical capillary number, then the viscous stress overrules the interfacial stress, and the drop is extended but does not break up. This process is called distributive mixing. Conversely, if the capillary number is much lower than the critical capillary number, then the interfacial stress dominates, and the drop is only slightly deformed.

In general, mixing begins with a distributive step (drops are deformed passively), followed by a dispersive step (drops break up into droplets), and finally by the distribution of the droplets in the flow. The following paragraphs focus on distributive mixing (Kinematic Parameters) and on distribution of material points into the flow domain (Distribution Mixing). A short paragraph presents also the quantities that can be used to evaluate the dispersive mixing.

One way to measure distributive mixing is to quantify the capacity of the flow to deform matter and to generate interface.

For 2D flows, the interface between fluids is a line. Instead of calculating the evolution of this interface (a very complex and impossible task to perform because of the exponential growth of the interface), the stretching of infinitesimal vectors attached to a large number of material points distributed in all the flow domain is calculated. As the points move in the flow, the vectors are stretched. The stretching and the rate of stretching of these vectors are properties that vary by time and location in the flow domain. Statistical analysis of the results provide a global overview of the process. Using this method, you have an objective and quantitative evaluation of the mixing of any process. You can, for example, find areas of poor mixing in the domain (low stretching instead of exponential increase). For 3D flows, the interface is a surface and the stretching of infinitesimal surfaces attached to material points is calculated.

Let and

denote the domain occupied by the homogeneous fluid at time 0

and

, respectively. The motion of the fluid is described by the

relationship

(34–1) |

where denotes the position of a material point

in

and

in

. The symbols

and

denote the deformation gradient and the right Cauchy Green

strain tensor between both configurations. The velocity gradient and the rate of

deformation tensor at time

are denoted by

and

, respectively. For later use, note that

(34–2) |

The dot denotes the material time derivative.

Kinematic Parameters for 2D Flows

Consider in , a material fiber

with a unit orientation

which deforms into a material fiber

with a unit orientation

at time

. With

denoting the length stretch

. It follows [4] that:

while is given by

(34–3) |

Good mixing quality requires high values of throughout time and space. A local evaluation of the

efficiency of mixing [5] is given by the ratio

(34–4) |

where

(34–5) |

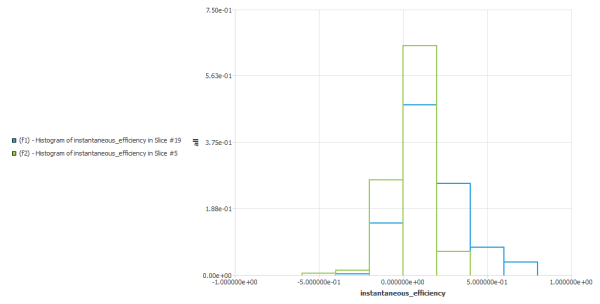

The values of this instantaneous efficiency are always included in the interval [-1; 1]. Through manipulation it follows:

(34–6) |

Note that is a local measure along the path of a material point. The

time-averaged efficiency is defined as

(34–7) |

The global efficiency over all of the material points initially distributed in the flow is defined as:

(34–8) |

This global efficiency is the ratio of the output—the mixing

obtained—(the total stretching of the matter until time ) over the input—the "energy" —(the total

mechanical dissipation until time

).

Kinematic Parameters for 3D Flows

For 3D flows, you can calculate the local stretching of infinitesimal surfaces

by the mean of the area stretch .

In the initial configuration , consider an infinitesimal surface

with a normal direction

. This surface deforms with time. At time

, the surface is noted

, with a new normal direction

. The area stretch

, is the ratio of the deformed surface

at time

over the initial surface

.

(34–9) |

For an incompressible fluid:

(34–10) |

If the fluid is incompressible, the normal direction to the surface

is:

(34–11) |

A good mixing quality requires high values of throughout time and space. A local evaluation of the

efficiency of mixing [5] is given by the ratio

(34–12) |

The values of this instantaneous efficiency are always included in the interval [-1; 1]. After some transformations:

(34–13) |

Note that is a local measure along the path of a material point; the

time-averaged efficiency is defined as

(34–14) |

For 3D kinematic parameters, a global efficiency over all the material points initially distributed in the flow is defined:

(34–15) |

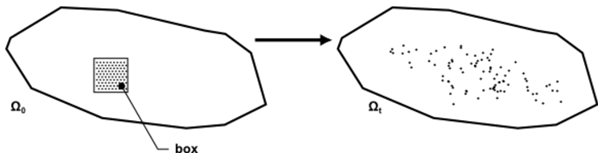

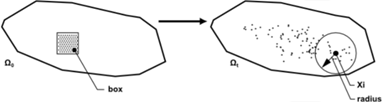

Suppose you want to distribute a cluster of particles initially concentrated in a small box (see figure below). It is assumed that the particles do not affect the flow field and that there is no interaction between them.

There exist several ways to quantify this process. Let us examine them one by one:

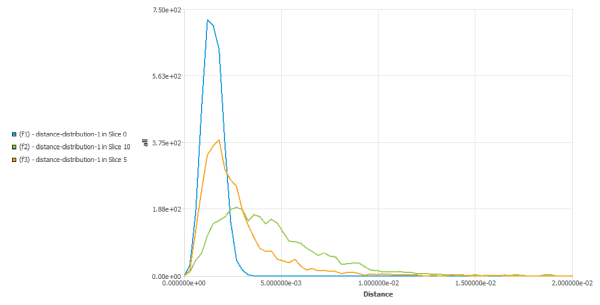

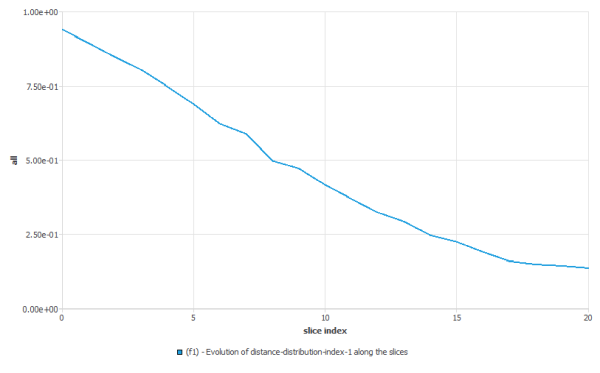

Distance distribution index:

The flow distributes this set of points as a function of time. We observe that the distance between points increase. It is important to define a distribution index to quantify this process. Its definition is based on the work performed by Manas-Zloczower and her colleagues [1], [2].

At time t, there are N points distributed in the flow domain.

Option 1: These points can form N(N-1)/2 pairs of points. For each pair of points xi and xj, their inter- distance

is calculated. The maximum inter-distance will be of the order of the diameter of the mixer.

Option 2: The inter distance

, between each point xi and its closest neighbour, xj is stored. Thus, we compute only N distances. Using this method of calculation helps to better discriminate distributive capabilities of similar mixers. The maximum inter-distance will be of the order of

, where V is the volume of the mixer.

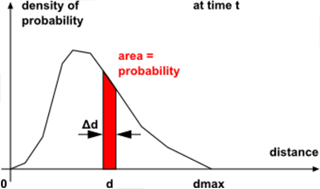

With this set of distances, we can calculate the density of probability function on the distance f(d) : the probability to find a pair of points (chosen randomly) such that their inter-distance is included in range

at time t is:

Now suppose you have randomly distributed the same number of points throughout the flow domain. You can assume that this is an ideal distribution. Using the same tools, you can calculate the function

for this optimal distribution. It is noted

.

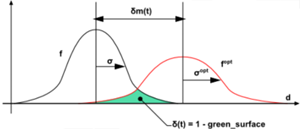

The distance distribution index,

, is defined as the deviation of the function f(d) (real distribution) from the function

(optimal distribution):

As the distribution improves, the index

decreases. This index is dimensionless — it is independent of the size of the flow domain. The evolution of

depends on the initial position of the box. Another important parameter is the number or material points to distribute; a careful analysis must be done to measure its influence.

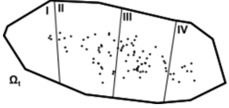

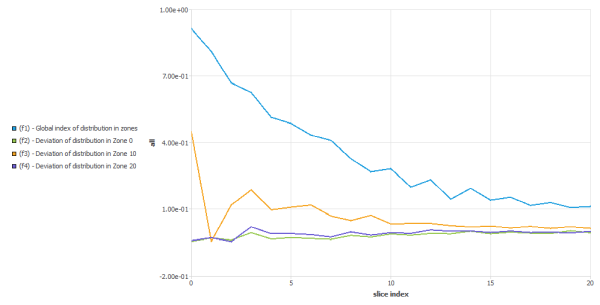

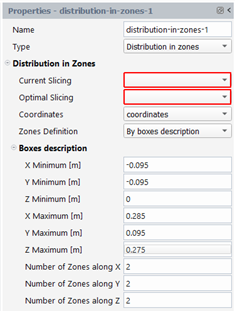

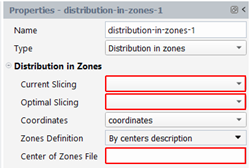

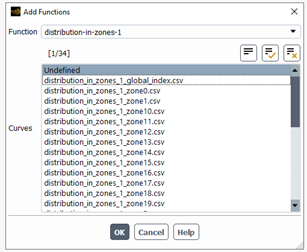

distribution in zones

The distance distribution index is a global index, and thus it is unable to detect local defects (part of the mixer with a lack or an excess of points). Using this next method, you can detect such zones. As for the distance distribution index, we start with a cluster of particles initially concentrated in a small box (see figure above “Distributing massless particles from a small box”). It is assumed that the particles do not affect the flow field and that there is no interaction between them.

As a function of time, the flow distributes this set of points. The flow domain is partitioned into a set of adjacent and non-overlapping zones. In the figure below, as an example, we divided the flow domain in four zones:

The same number of points

, is then distributed randomly throughout the flow domain (it is assumed that this is the optimal distribution).

One determines the number of points in each zone, for both distributions at time

. Based on these numbers, one can evaluate a relative error of distribution for each zone,

.

(34–16)

is the number of points of the real distribution included in zone

, at time

.

is the number of points of the optimal distribution included in the same zone.

If

is zero for a zone, the optimal number of points are in that zone.

If is negative for a zone, there is a lack of points in that zone as compared to the optimum.

If

is positive for a zone, there are too many points in that zone as compared to the optimum.

A global index based on all the zones is defined as,

(34–17)

The number of points and the zone partitioning influences the indices described above. When comparing two different mixers, it is recommended that you keep the ratio number of points and zones constant. In order to have relevant results, this ratio should be higher than 100.

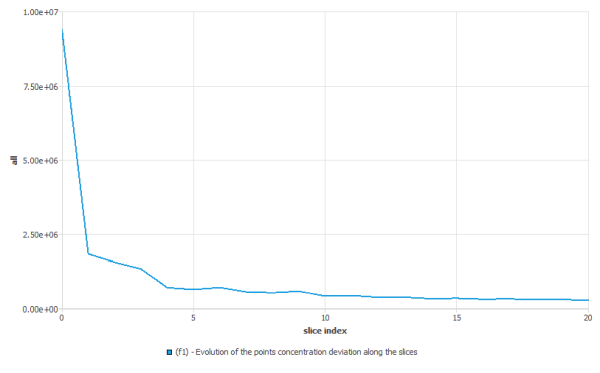

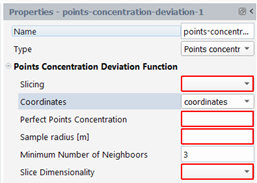

deviation of points concentration

As for the distance distribution index, the goal is to quantify distributive mixing. As for the previous parameters, there is a cluster of particles initially concentrated in a small box (see figure below).

As a function of time, the flow distributes this set of points.

At time t, there are N points distributed throughout the flow domain.

For each point xi, the number of neighbors xj, within a sample radius R are determined. Depending on the dimensionality (dim) of the cluster of points at time t, you can evaluate the local points concentration

:

where Nx is the number of points of the cluster around xi at a distance smaller than the radius R.

With a perfect distribution of the points, the points are equally distributed throughout the entire flow domain. That is, there are the same number of points per unit volume found everywhere in the domain. The perfect points concentration

, corresponds to the number of points divided by the volume of the flow domain. You can adapt this method for determining the perfect points concentration for other situations (see § Points Concentration Deviation Function).

The standard deviation of points concentration at time

is evaluated as

Where

is the number of points in the cluster at time

. xi corresponds to the location of point

at time

and

is the perfect points concentration.

Note that the points concentration is only evaluated at positions where there are points. There is no points concentration evaluation in zones of the mixer that do not contain material points. If distributive mixing improves, the points concentration deviation should decrease. At perfect distribution, the same points concentration is found at any location in the cluster, and the deviation is zero.

Dispersive mixing can also be analysed by adding postprocessors to the flow calculation:

Mixing index (or 'flow number') — indicates if the flow is locally a rigid motion (mixing index = 0), a shear flow (mixing index = 0.5), or in extension (mixing index = 1).

Stress — this field gives access to the stress magnitude in the direction of the local velocity (v.T.v) that stretches and breaks the drops.

Once the flow and those postprocessors are determined, you can calculate the evolution of the mixing index and the vTv stress component along the trajectories of material points. With these data you can evaluate the fraction of the matter experiencing a given stress value and evaluate the efficiency of the dispersive mixing.

Typically, trajectories are calculated by the time integration of the equation

with a Euler explicit scheme. This method is sufficient when only

interested in the successive positions of material points. However, a more accurate

numerical technique is required if you want to precisely know how matter deforms

around material points as they travel the flow domain.

The tracking module combines two techniques using explicit fourth order Runge-Kutta and a coordinate transformation is performed instead of integrating the motion of a particle in the real space. The trajectory in the parent element is integrated with the Runge-Kutta method.

(34–18) |

Successive positions of the particle in real space are calculated using:

(34–19) |

The tracking module algorithm is as follows:

Initialization

Find the element

, which contains the initial position

.

Find the local coordinates,

, of

in element

.

The algorithm solves using the following loop unless a stop is required:

Integrate Equation 34–18 until a boundary of element

is crossed.

If a boundary of

is crossed, a Newton-Raphson iterative procedure is adapted in such a way that the position is on the boundary.

Once on a boundary of

in

:

Search the element adjacent to

for where to continue the integration. This element is denoted as

*.

Determine the local coordinates

in element

of the current position

.

Return to step 2.a.

Note: Some numerical parameters of the algorithm may affect the accuracy of the calculation. For example, the Number of Steps per Cell indicates the mean number of integration steps necessary to cross an element.

This tool allows you to generate a set of pathlines for a large number of virtual particles, also named massless particles or material points hereafter, in complex flows such as transient flows involving the motion of moving parts. Along these pathlines, a set of quantities may be evaluated like velocity, pressure or temperature, but also quantities that may be useful to evaluate mixing process such as area stretch ratio, time averaged efficiency of mixing, and more. These pathlines are saved in various formats for further analysis (Fieldview, CFD-Post and Polystat). See Definition of a Statistics Task to define a statistical analysis on these pathlines sets.

Since Tracking requires the knowledge of the flow field,

it can be considered a postprocessor. To activate it, select

Solution

→ Outputs → More

Outputs → Tracking prior to solving

your flow calculation. See Limitations if

Tracking is not visible in the graphical user

interface.

Note: You can enable Tracking by selecting:

File → Preferences... → Materials

Processing → Tracking Outputs

.

Limitations

Tracking is not available for shell simulations, volume-of-fluid simulations and flow simulations with variable density, cutcell meshes (if the mesh has been refined by subdivision, if no conformalization was done) and simulations involving non-conformal fluid-fluid interfaces.

When the flow field is the result of a continuation approach, the flow field of the last step (considered a steady flow) will be used to perform the computation of the pathlines.

For transient flow fields, the flow must be saved at a constant and exact time step.

When using the Mesh Superposition Technique (MST) with moving or restrictor parts (with or without slippage along the parts walls), the trajectories and kinematics of the deformation may be affected when material points (massless particles) are close to the surface of the parts.

When using the Mesh Superposition Technique (MST) with moving parts, some virtual particles get overlapped by a moving part. This is due to the accumulation of small errors when calculating the successive positions of the virtual particles. There are two ways (which can be combined) to limit this issue:

Decrease the time step between two successive flows.

Refine the flow domain mesh.

Tracking must not be used if the mesh of the flow domain changes with time (changes in coordinate position of the mesh vertices and/or number and shape of mesh elements). This does not include the use of the Mesh Superposition Technique with moving parts on a transient flow field, as the underlying mesh remains constant.

In some cases, material points may stop on an impermeable boundary (wall, free surface, plane of symmetry) due to stagnation of the flow field in close proximity to these boundaries. This can have a dramatic effect on the flow statistics, particularly if you are analyzing an open flow field (with entry and exit of fluid). The number of points at entry and exit may differ significantly and therefore bias the statistics.

There are two ways of launching the Tracking tool. You can launch it from the Outline View or the ribbon:

Tracking

Tracking

Firstly, on the flow domain, define where tracking of virtual particles will be done. Next, define the zones that will be the source of the virtual particles (their starting location). Then, select the quantities that will be evaluated along the pathlines for further analysis. Prior to launching the calculation, specify numerical parameters (the number of virtual particles, their lifetime, the format of the files containing the pathlines, etc..). Once this setup is complete, you can begin the computation.

After the calculations end, pathlines can be visualized and analysed using other tools (Fieldview, Ansys CFD-Post and Ansys Polystat).

To start Polystat (with the automatic loading of the generated files) from

Fluent Materials Processing, select: Tracking → Run

Calculation Polystat

To start CFD-Post from Fluent Materials Processing, select: Tracking

→ Run Calculation CFD-Post

or use the ribbon:

Tracking

→ Domain

Under Domain, by default, Zones

are initialized to fluid cell zones defined in

Setup → Cell

Zones. However, you can select specific parts of the fluid

domain if needed. Moreover, you can also enable and define a

Bounding Box overlapping (at least partially) the

tracking domain. The pathline of a material point will be pursued until it

crosses a face of that bounding box, or until its lifetime is reached, or

until it stops on a boundary of the tracking domain. The Bounding

Box is defined by two corners, the lower-left-front corner

and the upper-right-back corner.

Tracking → Domain

Tracking

→ Sources

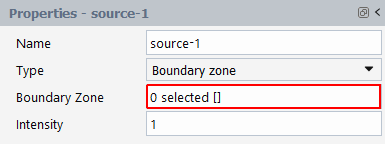

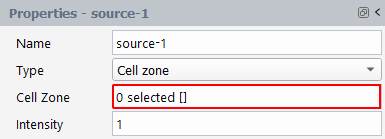

Sources allow you to define zones where material points are initially positioned. You must have at least one source zone selected to have a well-defined tracking task. Sources are not defined by default.

Tracking → Sources

New...

The following source types are available under Type:

You can specify the inlet of the domain if the flow domain is open (entry and exit of fluid exist). Virtual particles will be randomly generated in the selected face zones.

Intensity identifies the relative number of points generated in the various sources. For example, if you define two sources with Intensity

1and3respectively, every pathline computed from source-1 will have three pathlines beginning from source-2.

You can specify a part of the tracking zone (or the whole tracking zone) if the flow domain is closed (no entry and exit of fluid). The virtual particles will be randomly generated in the selected cell zones.

The Intensity identifies the relative number of points that are generated in the various sources. For example, if you define two sources with Intensity

1and3respectively, every pathline computed from source-1 will have three pathlines beginning from source-2.Imports a .csv (comma-separated values) file containing a list of initial positions of virtual particles.

The format of the .csv file may contain several sections. Each section contains the initial value of a given quantity for all material points. The first section must be for the

COORDINATES. The other sections may be used fortime,space_integration,direction_of_stretching,logarithm of stretchingandlabel.Important: Other names will not be recognized.

COORDINATES 1; 0.1000000E+01; 0.0000000E+00; 0.0000000E+00; 2; 0.2000000E+01; 0.0000000E+00; 0.0000000E+00; 3; 0.3000000E+01; 0.0000000E+00; 0.0000000E+00; .. 10; 0.5000000E+01; 0.1000000E+00; 0.0000000E+00; time 1; 0.1000000E+01; 2; 0.2000000E+01; 3; 0.3000000E+01; .. 10; 0.1000000E+02;

Each section is separated by an empty line. The first line of each section contains the name of the quantity (upper case letters mandatory for COORDINATES, lower case for all other quantities). The following lines contain all numbers and reals separated by a semi-colon. These lines must end with a semi-colon. The first integer is the index of the material point, the other reals on the same line correspond to the initial value of the quantity component for that material point. COORDINATES and direction_of_stretching must have three components, while the other quantities only should have one component. The indexes must be identical throughout all sections.

Note: The Intensity property does not apply for CSV File sources, as you will compute the pathlines of all virtual particles defined in the .csv file.

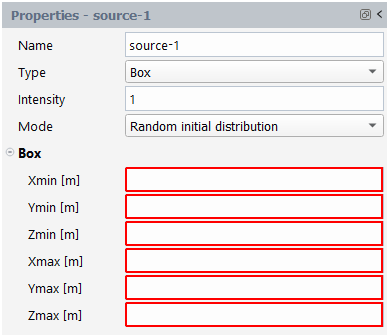

Locate the initial position of the material points in a box overlapping (at least partially) the tracking domain.

The box is defined by the coordinates of its two extreme corners:

Xmin [m], Ymin [m] and Zmin [m] for the lower-left-front corner.

Xmax [m], Ymax [m] and Zmax [m] for the upper-right-back corner.

There are two modes to generating the initial positions:

The initial positions of the material points are randomly generated in the box.

With this mode of generation, Intensity is required. The Intensity identifies the relative number of points that are generated in the various sources. For example, if you define two sources with Intensity

1and3respectively, every pathline computed from source-1 will have three pathlines beginning from source-2.

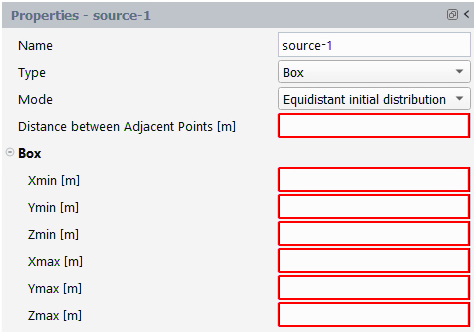

The material points, specified by you, are initially distributed at equal distance (

) between neighboring points. If the flow domain is 2D, the points are distributed at vertex positions of a lattice of identical equilateral triangles (see Figure 34.11: Equidistant Distribution of Points in a 2D Box). If the flow domain is 3D, the points are distributed at locations corresponding to the centers of close-packed equal spheres. The generated points that are outside the flow domain will be rejected.

Tracking

→ Quantities

A number of quantities can be evaluated along pathlines and are available in the Quantities panel.

Note: Quantities availabilities are dependent on a few conditions.

The current type of simulation opened (for example, the quantity is unavailable if your simulation is not thermal based).

The quantity not being previously evaluated as a derived quantity when computing the flow field.

Other quantities require another quantity to become available first (for example, requires and ).

Time and coordinates quantities are always saved.

You should only enable the quantities necessary for your study to save computation time and memory usage.

Space Integration

Enable to get the length of a trajectory up to the time

.

Rate of Stretching

Enable to get the rate of stretching

(3D flow) or

(2D flow). See Quantification of Mixing (Theoretical Background) for more details.

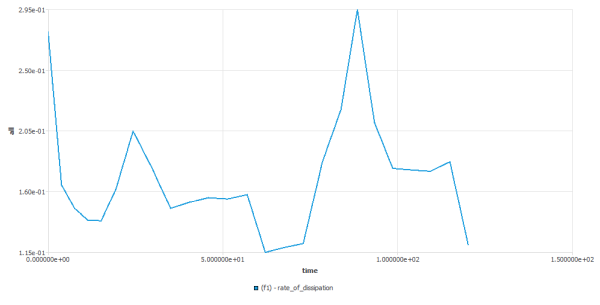

Rate of Dissipation

Enable to get the rate of dissipation

. It is the magnitude of the rate of deformation tensor

.

See Quantification of Mixing (Theoretical Background) for more details.

Cumulated Dissipation

Enable to get the cumulated dissipation

along the pathlines. This quantity is shown if the quantity “rate of dissipation” is enabled.

Dc =

where

is the time and

is the rate of dissipation.

See Quantification of Mixing (Theoretical Background) for more details.

Direction of Stretching

Enable to get the direction of stretching n (3D flow) or m (2D flow) along the pathlines.

See Quantification of Mixing (Theoretical Background) for more details.

Logarithm of Stretching

Enable to get the logarithm of stretching

(3D flow) or

(2D flow) along the pathlines.

See Quantification of Mixing (Theoretical Background) for more details.

Instantaneous Efficiency of Stretching

Enable to get the instantaneous efficiency of stretching along the pathlines. It is defined as the ratio of the rate of stretching to the rate of dissipation. This quantity is available when and are enabled.

For 3D flows:

=

For 2D flows:

=

where

is the rate of dissipation and

or

are the rate of stretching in 3D or in 2D flows respectively.

See Quantification of Mixing (Theoretical Background) for more details.

Time Averaged Efficiency of Stretching

For 3D flows: <

> =

For 2D flows: <

> =

where

is the time,

is the rate of dissipation,

is the cumulated dissipation and

,

are the logarithm of stretching for 2d and 3D flow respectively.

See Quantification of Mixing (Theoretical Background) for more details.

Velocities

Enable to get the local velocity along the pathlines.

Pressure

Enable to get the local pressure along the pathlines.

Temperature

Enable to get the local temperature along the pathlines. This quantity is shown if the simulation is thermal based.

Shear Rate

Enable to get the local shear rate

along the pathlines. This quantity is shown if Rate of Dissipation is enabled. The local shear rate can be defined as:

where

is the rate of dissipation and

is the rate of deformation tensor.

Shear Viscosity

Enable to get the local shear viscosity along the pathlines. This quantity is available if the Viscosity derived quantity is enabled.

Stress Magnitude

Enable to get the local stress magnitude (stress in the direction of the velocity

) along the pathlines. This quantity is available if the Stress derived quantity is enabled.

Mixing Index

Enable to get the local mixing index

along the pathlines, It provides a local measure of the dispersive mixing efficiency (see chapter 7 of [6]). This quantity is available when the Mixing Index derived quantity is enabled.

The Mixing Index

is defined as:

where

is the shear rate and

is the magnitude of the vorticity vector. The mixing index

indicates, locally, whether the flow is rigid (Mi = 0), a shear flow (Mi = 0.5), or an extensional flow (Mi = 1).

Melting Index

Enable to get the local melting index

along the pathlines. This quantity is shown if the quantities Temperature and Shear Viscosity are enabled.

The Melting Index, (used in [3] to characterize the quality of the glass melting in a furnace), is defined as:

where

is the time,

is the shear viscosity and

is the temperature.

Determinant of Tensor F (det F)

Enable to measure the accuracy of the computation. As flow is incompressible, it should remain equal to 1 along any pathline.

Divergence of Velocities (div V)

Enable to measure the accuracy of the computation. As flow is incompressible, it should remain equal to 0 along any pathline.

Tracking

→ Controls

In the Controls panel, you can define the parameters necessary to initialize the kinematic quantities, provide some characteristics of the flow field, evaluate accurately the pathlines and specify the mode of storage of the trajectories.

Lifetime [s]

Allows you to specify the lifetime of each virtual particle. Once this value is reached, Fluent Materials Processing stops to evaluate the pathline of the current virtual particle.

Velocity Magnitude [m/s]

Specify the typical velocity magnitude of the particles. The average velocity magnitude of the flow field can be provided.

Flow Regime

This option is available for transient flows only. You specify whether the flow is continuous transient or piecewise steady.

Start Id

This option is available for transient flows only. For tracking tasks, it is assumed that the flow is periodic. You must specify which time step will be the first to be used for the pathlines evaluation (first, last, or intermediate). During pathline evaluations, you use the flow fields of each time step in a loop until the lifetime of the particles is reached.

Intermediate Step

This option is only available for transient flows and when Start Id has been set to . Specify the initial step used for pathline evaluations.

Constraint on Tensor F

This option is available for 2D flows only. By enabling this option, you normalize the tensor F regularly during the pathline evaluation allowing its determinant to remain equal to 1.

Initial Stretching Direction

This option is used for stretching quantities. An initial vector must be specified for each virtual particle. For example, random (different for each virtual particle) or imposed (same for all virtual particles). When the virtual particle travels within the flow, the vector will reorient and stretch.

Imposed Direction

Dx, Dy, Dz

When specifying Initial Stretching Direction, you can specify the X, Y, Z components of the vector N (if flow is 3D) or M (if flow is 2D).

Storage Controls

Storage Mode

Various modes of storage are available to store virtual particle positions such as , , , , .

Note: In regards to memory consumption, consumes the most. When the flow field is transient, , are preferred. While for steady flows with an inlet/outlet, , are preferred.

Time Step [s]

Specify the time step before storing the position of a virtual particle.

Displacement [m]

Specify the displacement before storing the position of a virtual particle.

Maximum Number of Files

Specify the number of files that will contain pathlines. It is preferable to have multiple, smaller sized files rather than a large one.

Maximum Number of Pathlines per File

Specify the maximum number of pathlines that will be saved in a single file.

Maximum CPU Time per File [hour]

Specify the CPU time needed to generate a file. As soon as the specified CPU time is reached, the current file is closed and another is created to contain the next pathlines.

Save in Polyflow MIX Files

Enable to generate Ansys Polyflow *.mix files containing the pathlines (*.mix files are mandatory to perform statistical analysis).

Save in CFD-Post TRK Files

Enable to generate CFD-Post *.trk files containing the pathlines.

Save in Fieldview FVP Files

Enable to generate Fieldview *.fvp files containing the pathlines.

Advanced Controls

Relative Tolerance on a Distance

This option is an advanced parameter used to evaluate the pathlines. A point is considered on the border of a finite element if its distance (in the parent element) to the border is less than this tolerance.

Relative Tolerance on a Velocity

This option is an advanced parameter used to evaluate the pathlines. A point is considered as a stagnation point if its velocity (in the parent element) is less than this tolerance.

Relative Tolerance on a Time

This option is an advanced parameter used to evaluate the pathlines. A time step is considered as negligeable if it is less than this tolerance. It will be used to stop the iterative Newton-Raphson procedure that finds the time step needed to reach the border of the current finite element containing the point.

Number of Steps per Cell

This option is an advanced parameter used to evaluate the pathlines. You indicate how many Runge-Kutta steps a particle will cross each finite element. The initial time step of integration for each element is determined by the following formula.

Initial time step in element E = Size(E) / velocity magnitude / number of steps per cell

Keywords

Advanced option for the solver and should not be used unless recommended by Ansys Customer Support.

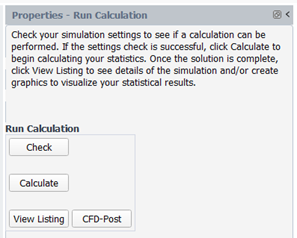

Once all Tracking parameters are defined, you can

launch your calculation using Tracking

→ Run Calculation

The following are available to you within the Properties - Run Calculation panel:

Verify and ensure the setup of your tracking simulation is valid. Any relevant messages are displayed in the Console window notifying you of any discrepancies.

Once your setup is valid, click to start the solver.

Pauses the solver once the calculation has started.

Interrupts the solver once the calculation has started.

Restarts the solver and completes the interrupted calculation.

Allows you to view instructions about the solution transcript once the calculation completes. It is available as a docked tab next to the Graphics window.

It allows to start CFD-Post in order to see the pathlines saved (if asked by the user) in *trk files.

Polyflow .mix files can be loaded into Polystat for

visualization and statistical analysis. To launch Polystat from Fluent Materials Processing,

select Tracking → Run

Calculation Polystat

The .mix files can be found in the Tracking directory under the project directory.

CFD-Post .trk files can be loaded into CFD-Post for

visualization. To launch CFD-Post from Fluent Materials Processing, select

Tracking → Run

Calculation CFD-Post.

The .trk files can be found in the Tracking directory under the project directory.

The Fieldview .fvp files can be loaded into Fieldview for visualization. Fieldview can only be launched outside of Fluent Materials Processing. The .fvp files can be found in the Tracking directory under the project directory.

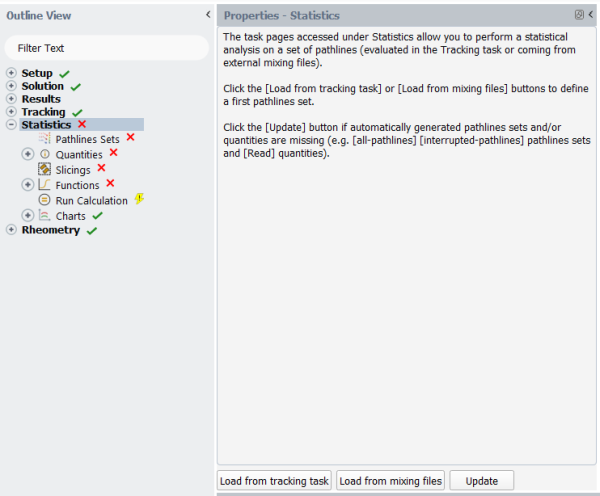

This section describes the following topics:

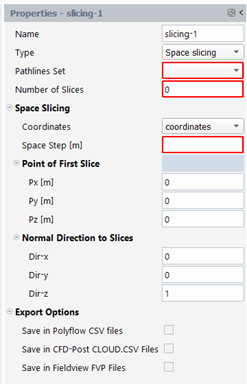

After the calculation of a large set of pathlines (performed previously in the Tracking tab), it is now possible to treat those results to obtain a global and objective overview of the mixing process (but not only) in the current flow. To achieve this goal, one performs a statistical treatment on the pathlines. We consider here two kinds of flow: steady state flows with inlet and outlet sections (flow in an open domain) or transient flows in a closed domain (with or without moving parts). We are interested to analyse the evolution of some properties during the process: as a function of “space”, for open domains, from the inlet to the outlet, or as a function of time for closed domains. We define thus a slicing on the pathlines (a set of cutting planes for open domains, and a set of times for closed domains): for each slice, we get thus a sampling of values on which we can perform some statistical treatment. With such a method, e.g., we can analyse how stretching evolves in a kenics mixer or in a batch mixer. We can also analyse the distribution of materials points initially concentrated in a small box.

To achieve this goal, one performs a statistical treatment on the pathlines. This is done in several steps.

Under the Pathlines Sets node, you can specify the pathlines that will be used for the statistical task: they are provided by the Tracking task, or by loading mixing files coming from another project. Moreover, you can create “derived” pathlines sets based on these primary sets: by filtering them, or through Boolean operations applied on them. For example, you can eliminate all the trajectories that terminated abnormally (for example, on a wall). Moreover, specific kinds of pathlines sets are also provided: it is possible to extract a single pathline from a set, or to detect stagnation points.

Under the Quantities node, as soon as you have uploaded pathlines, a set of quantities will become visible. You can ask to calculate new quantities evolving along the trajectories. For example, you can define any concentration field, extract a component of a vectorial quantity, or ask for the magnitude of a quantity. These new quantities are always a combination of existing quantities (those calculated previously and stored in the mixing result files).

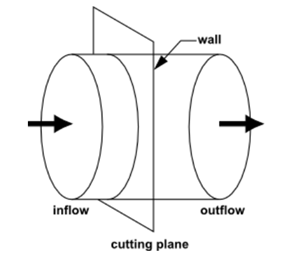

Under the Slicing node, you determine the way to slice the selected trajectories. For example, suppose you are analyzing the flow through a cylinder, like the one shown in the following picture:

To analyze this flow, locate a set of material points in the inflow

section, and calculate their trajectory until they reach the outflow section.

You will then cut the pathlines with planes disposed regularly from the entry to

the exit (this is the slicing step). In each plane, you will calculate

statistical functions. Those functions will evolve from entry to exit and show

the way the mixing changes (among other characteristics, because one can perform

statistics on any quantities as soon as they are known along the pathlines. E.G.

residence time, temperature, shear rate, ..). Note: If the flow occurs in a

closed domain, you want to know the time evolution of statistical functions and

the slicing will be done on the time.

Under the Functions node, you define the set of statistical functions that you want to calculate on the defined set of slices. E.G. probability, density of probability, histograms, .. on quantities. But one can also define more specific functions to evaluate the distribution mixing.

Under the Run Calculation node, you will be able to calculate effectively the defined pathlines sets, slicings and functions. This calculation can take a while to complete. A summary is provided to check the solver actions.

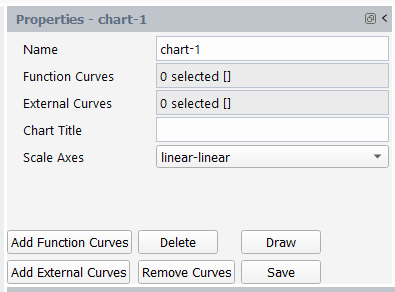

Under the Charts node, you will be able to define charts to visualize your statistical functions.

Eventually, it is also possible to export pathlines sets, slicings and functions to visualize them in CFD-Post, Fieldview, Polystat and Excel. NB. Only Polystat allows you to visualize easily pathlines in transient flows involving moving parts.

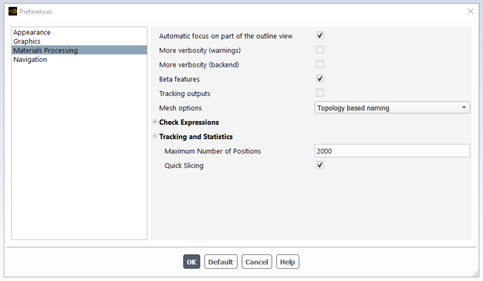

Two properties may affect the pathlines and statistics calculations:

Maximum number of positions: the computation of a single pathline may involve many intermediate positions from the starting point until it reaches the exit and/or its lifetime. In general, it is not necessary to store all these positions for further statistical analysis. With this property, you limit the number of stored positions. By this way, we also reduce the size of the mixing files and accelerate the statistics computation.

Quick Slicing: when performing a space slicing, a pathline may cross several times the same slice (E.G., when backflow is present). By enabling this property, we search only for the first intersection between the pathline and the slice. By this way, we accelerate the statistics computation and avoid some statistical bias (a single material point counted several times).

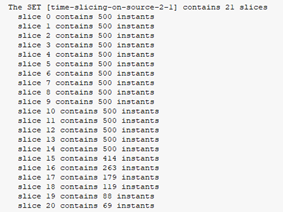

When we do statistics on a population of material points, two important points must be kept in mind:

the population of material points must be large enough to get accurate and objective statistics. Especially if one wants to compare different setups and/or geometries.

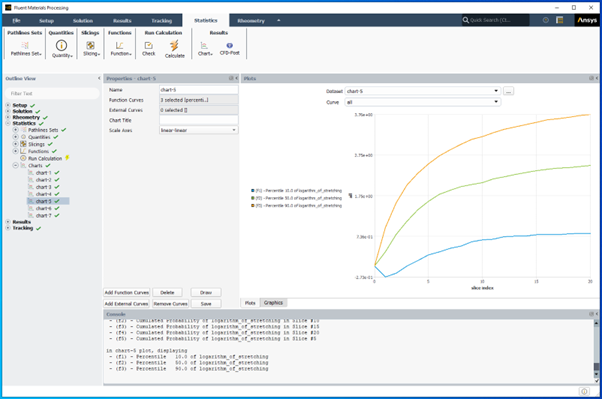

as we calculate statistical functions on a set of slices, it is important to remember that each slice should contain (almost) same number of instants. If the number of instants decreases too much, the statistics will be biased. We can check that number in the transcript window (click on “View Listing” in the Run Calculation panel): in the following example, we see that the number of instants diminishes dramatically after slice #14, leading to unusable statistics.

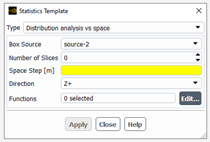

In order to facilitate definition of a statistical analysis based on set of pathlines evaluated earlier in the tracking task (of the same project), a few templates are available:

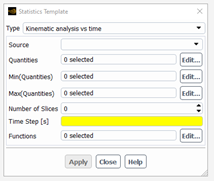

Kinematic analysis vs time

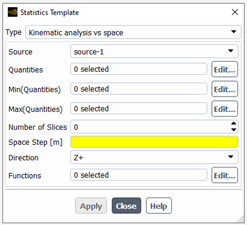

Kinematic analysis vs space

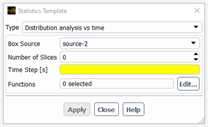

Distribution analysis vs time

Distribution analysis vs space

These templates can be found in the ribbon, on the Statistics page:

Click on “Use Template..”: a popup-menu appears where you can select the template type:

For the Kinematic analysis vs time, we assume that the flow occurs in a closed domain (no inlet, no outlet) and changes with time (e.g. in a batch mixer). We are interested here to analyse how the stretching of small pieces of matter attached to the material points and/or other quantities evaluated along the pathlines in the tracking task (e.g. temperature, shear stress, mixing index, ..) change with time. The user will have to specify the source of the material points (defined in the tracking task), a few parameters to define the slicing along the time (number of slices, time step – we assume the time starts at t=0 s), select the quantities (including the minimum and the maximum of some quantities) he wants to summarize in a few statistical functions, and eventually, choose the statistics to perform.

When all the properties of the panel are defined, click on “Apply” : the panel closes and the Fluent Materials Processing App will generate all the relevant objects (pathlines sets, quantities, slicings and functions) and populate the Statistics sub-tree in the Outline View. Once this is done, the user can modify or fill some missing properties. Eventually, he can check the setup and start the calculation, by clicking on “Check” or “Calculate” buttons respectively in the ribbon (in the Statistics page). After the calculation, the user will have to define a few charts to visualize his results.

For the Kinematic analysis vs space, we assume that the flow occurs in an open domain (with inlet and outlet) and is steady state (e.g. in a Kenics mixer). We are interested here to analyse how the stretching of small pieces of matter attached to the material points and/or other quantities evaluated along the pathlines in the tracking task (e.g. temperature, shear stress, mixing index, ..) evolve from the inlet to the outlet of the flow domain. To do so, we have to define a set of cutting planes starting at inlet and located at regular space step in the flow direction (supposed to be aligned with one axis). The user will have to specify the source of the material points (defined in the tracking task), a few parameters to define the slicing in space (number of slices, space step, direction of slicing (X+, Y+, Z+, X-, Y- and Z-), select the quantities (including the minimum and the maximum of some quantities) he wants to summarize in a few statistical functions, and eventually, choose the statistics to perform.

When all the properties of the panel are defined, click on “Apply” : the panel closes and the Fluent Materials Processing App will generate all the relevant objects (pathlines sets, quantities, slicings and functions) and populate the Statistics sub-tree in the Outline View. Once this is done, the user can modify or fill some missing properties: it is important here to check the parameters of the slicing, specially, the initial slice position and the normal direction to the slices. Eventually, he can check the setup and start the calculation, by clicking on “Check” or “Calculate” buttons respectively in the ribbon (in the Statistics page). After the calculation, the user will have to define a few charts to visualize his results.

For the Distribution analysis vs time, we assume that the flow occurs in a closed domain (no inlet, no outlet) and changes with time (e.g. in a batch mixer). We are interested here to analyse how the material points initially concentrated in a box will spread and fulfill the whole flow domain. In the tracking task, two sources must have been defined: one box and the whole flow domain. The user will have to specify the box source of the material points, a few parameters to define the slicing along the time (number of slices, time step – we assume the time starts at t=0 s), and choose the statistics to perform: 3 functions are available (distance distribution, distribution in zones and axial distribution), each one requiring to define some properties:

Distance distribution: maximum distance (see the paragraph on “distance distribution function” for further details)

Distribution in zones: zone size (see the paragraph on “distribution in zones” for further details). The number of zones in each direction will be evaluated assuming the size of the smallest box surrounding the whole mesh:

Number of zones along X = round[abs(xmax-xmin)/zone_size]

Number of zones along Y = round[abs(ymax-ymin)/zone_size]

Number of zones along Z = round[abs(zmax-zmin)/zone_size]

Axial distribution: axis (X, Y, Z)

In this case, we define a new quantity (of “extract” type) based on the component of the coordinates selected as the axis. We will see how the values of this component spread with time (for the set starting from the box), and how this distribution matches the perfect distribution (corresponding to the set defined on the whole flow domain).

When all the properties of the panel are defined, click on “Apply” : the panel closes and the Fluent Materials Processing App will generate all the relevant objects (pathlines sets, quantities, slicings and functions) and populate the Statistics sub-tree in the Outline View. Once this is done, the user can modify or fill some missing properties. Eventually, he can check the setup and start the calculation, by clicking on “Check” or “Calculate” buttons respectively in the ribbon (in the Statistics page). After the calculation, the user will have to define a few charts to visualize his results.

For the Distribution analysis vs space, we assume that the flow occurs in an open domain (with inlet and outlet) and is steady state (e.g. in a Kenics mixer). We are interested here to analyse how the material points initially concentrated in a box located in the inlet will spread and fulfill the flow domain and especially the outlet section. To do so, we have to define a set of cutting planes starting at inlet and located at regular space step in the flow direction (supposed to be aligned with one axis). Previously, in the tracking task, two sources must have been defined: one box located in the inlet and the inlet. The user will have to specify the box source of the material points (defined in the tracking task), a few parameters to define the slicing in space (number of slices, space step, direction of slicing (X+, Y+, Z+, X-, Y- and Z-), and choose the statistics to perform: 2 functions are available (distance distribution and distribution in zones), each one requiring to define some properties:

Distance distribution: maximum distance (see the paragraph on “distance distribution function” for further details)

Distribution in zones: zone size (see the paragraph on “distribution in zones” for further details). The number of zones in each direction (other than the flow direction) will be evaluating assuming the size of the smallest box surrounding the whole mesh:

Number of zones along X = round[abs(xmax-xmin)/zone_size]; (reset to 1 if flow direction is X+ or X-)

Number of zones along Y = round[abs(ymax-ymin)/zone_size]; (reset to 1 if flow direction is Y+ or Y-)

Number of zones along Z = round[abs(zmax-zmin)/zone_size]; (reset to 1 if flow direction is Z+ or Z-)

When all the properties of the panel are defined, click on “Apply” : the panel closes and the Fluent Materials Processing App will generate all the relevant objects (pathlines sets, quantities, slicings and functions) and populate the Statistics sub-tree in the Outline View. Once this is done, the user can modify or fill some missing properties: it is important here to check the parameters of the slicing, specially, the initial slice position and the normal direction to the slices. Eventually, he can check the setup and start the calculation, by clicking on “Check” or “Calculate” buttons respectively in the ribbon (in the Statistics page). After the calculation, the user will have to define a few charts to visualize his results.

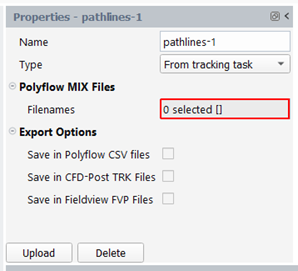

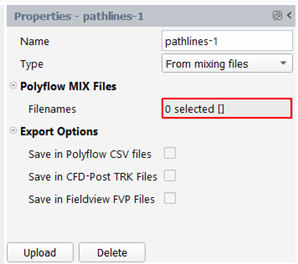

We specify here the different pathlines on which we will perform a statistical analysis. There are several types of pathlines sets, but one need at least one set of the “From tracking task” type or of the “From mixing files” type.

To create them, go in the "Statistics" properties panel:

and click on the "Load from tracking task" or "Load from mixing files" buttons to create the corresponding sets and load the mixing files (a specific "Load" button must be clicked in these sets to perform effectively the loading - this is not automatic).

After the load, some new pathlines sets are created together with a list of quantities. See below for further details.

Once the type is selected, new properties become visible:

For "From tracking task" type: one has to load the mixing files computed in the tracking task (meaning that this part of the project must be up-to-date). To do so, click on the "Load" button at bottom of the property panel. After the loading, the Filenames property should be completed, and some new pathlines sets (all pathlines, interrupted pathlines) and quantities (the quantities asked for in the tracking task) should appear in the Outline View.

For “From mixing files” type: one has to load the mixing files computed in another project. To do so, click on the “Load” button at bottom of the property panel. One has to specify in a browser the mixing files to be loaded. After the loading, the Filenames property should be completed, and some new pathlines sets (all pathlines, interrupted pathlines) and quantities (the quantities asked for in the tracking task) should appear in the Outline View.

For “All pathlines” and “Interrupted pathlines”, no additional property is available. These two sets are automatically created after an “Load” action (see the two previous paragraphs).

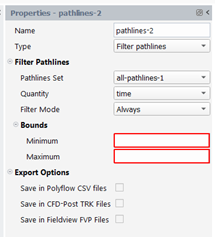

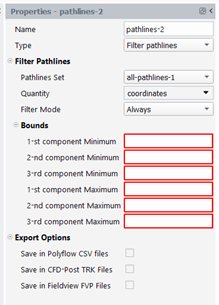

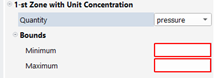

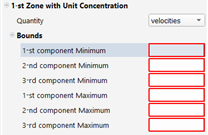

For “Filter pathlines” type, we will select a sub-set of pathlines, from another one, that respects some condition. The following properties must be specified:

Pathlines Set: enter the pathlines set on which the filtering will be applied.

Quantity: enter the quantity to be used to define the condition

Filter Mode: “Always”, “One time (at least)”, “Never”

Bounds: if the quantity is a scalar, a minimum and a maximum must be provided. If the quantity is a vector, a range for each component of the vector.

If one uses the “Always” filter mode, we keep a pathline if the selected quantity is always in the specified bounds.

If one uses the “One time (at least)” filter mode, we keep a pathline if the selected quantity is for a single position (at least) in the specified bounds.

If one uses the “Never” filter mode, we keep a pathline if the selected quantity is always out of the specified bounds.

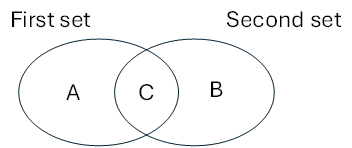

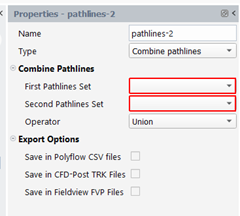

For “Combine pathlines” type, we will perform some boolean operation between two pathlines sets. Four operators are available:

Union: the new set will contain the pathlines of both sets (A+B+C in picture below)

Intersection: the new set will contain the pathlines that belong to the two sets (C in picture below)

Minus: the new set will contain the pathlines of the first set that do NOT belong to the second set (A in picture below)

Difference: the new set will contain the pathlines that belong to each set but do not belong to the other set (A+B in picture below)

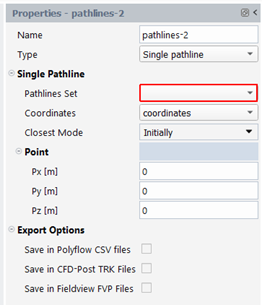

For “Single pathline” type, we will select one pathline from a set that respects some condition. The following properties must be specified:

Pathlines Set: enter the pathlines set on which the search will be applied.

Coordinates: enter the coordinates quantity to be used to define the condition

Closest Mode: “Initially”, “At any moment”

Point: provide here a position

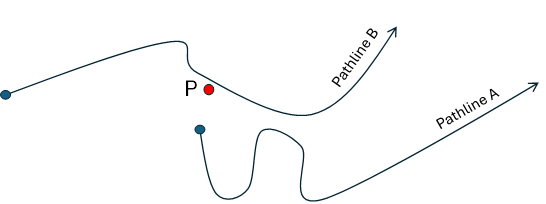

If one uses the “Initially” closest mode, we keep the pathline whose starting position is the closest to the specified point. (Pathline A in the figure below)

If one uses the “At any moment” closest mode, we keep the pathline whose the distance is the minimum to the specified point. (Pathline B in the figure below)

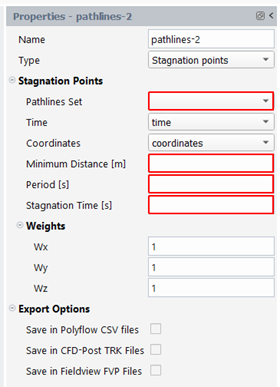

For “Stagnation points” type, we want to determine if some stagnation points exist among a pathlines set. Two kinds of stagnation points may be searched: the one close to a fixed wall, the one that are close to a rotating wall (moving part), and that have a circular path.

The following properties must be specified:

Pathlines Set: enter the pathlines set on which the search will be applied.

Time and Coordinates quantities

Minimum Distance: a point is stagnant if the distance between its initial position and some of its successive positions are less than this minimum distance.

Period P:

To detect stagnation points close to a fixed wall, the period P may take any value. However, if you want to detect stagnation points close to a rotating wall (of a moving part, for example), you have to specify the period P of rotation of the moving part.

Only the positions

, for time

, corresponding to a multiple of P will be tested, from 0 until stagnation time. For example,

will be tested at times

stagnation time

Stagnation time: must be less than the residence time

Weight

: it is a way to weight specifically some components of the coordinates when computing distance between

and

:

By default, the weights are set to 1

The Export Options are always available: with these properties, one can export pathlines sets for further analysis in other tools. Enable the outputs of interest:

Save in Polyflow CSV files: csv files are generated for analysis in Excel.

Save in CFD-Post TRK files: trk files are generated for visualization in CFD-Post.

Save in Fieldview FVP files: fvp files are generated for visualization in Fieldview.

All the files will be stored in the Statistics/Outputs directory under the project directory.

We specify here the quantities of interest for further statistical analysis: among of them, some quantities are automatically created after the definition of pathlines sets (of type: “from tracking task” and “from mixing files”). These quantities cannot be modified. Moreover, the user can define new quantities, based on “Read” quantities but also on the ones the user has created: by this way, it can define complex quantities relevant for his process. Be careful not to define circular dependencies between quantities. Note that if you save the pathlines sets by using the Export Options (see above for further details), the new quantities will be also available for visualization (in Polystat, CFD-Post or Fieldview, depending on the saving options that were enabled).

We will now examine them.

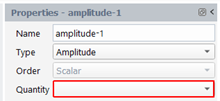

Amplitude

We create a quantity that is the absolute value of a scalar quantity or the magnitude of a vector quantity. The result quantity is a scalar. Select “Amplitude” for the Type and select the input quantity in the drop-down list “Quantity” in the property panel:

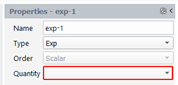

Exponential

We create a quantity that is the exponential of a scalar quantity. The result quantity is a scalar. Select “Exp” for the Type and select the input quantity in the drop-down list “Quantity” in the property panel:

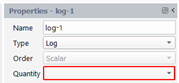

Logarithm

We create a quantity that is the natural logarithm of a scalar quantity. The result quantity is a scalar. Select “Log” for the Type and select the input quantity in the drop-down list “Quantity” in the property panel:

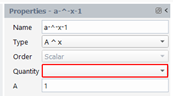

A ^ x

We create a quantity that is the exponent of a positive constant A by a scalar quantity. The result quantity is a scalar. In the property panel, select “A^x” for the Type, select the input quantity in the drop-down list “Quantity” and define the positive constant A:

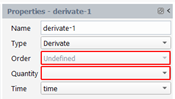

Time Derivation

We create a quantity that is the time derivation of another quantity. The result quantity can be a scalar or a vector, depending on the order of the input quantity. The accuracy of this quantity is dependent on the number of instants stored along each pathline: few instants will lead to poor evaluation of the derivate. In the property panel, select “Derivate” for the Type, select the input quantity in the drop-down list “Quantity” and select the time quantity:

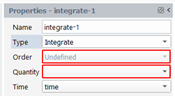

Time Integration

We create a quantity that is the time integration of another quantity. The result quantity can be a scalar or a vector, depending on the order of the input quantity. The accuracy of this quantity is dependent on the number of instants stored along each pathline: few instants will lead to poor evaluation of the integral. In the property panel, select “Integrate” for the Type, select the input quantity in the drop-down list “Quantity” and select the time quantity:

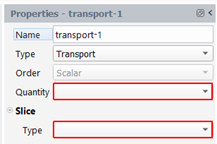

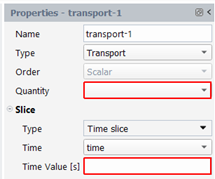

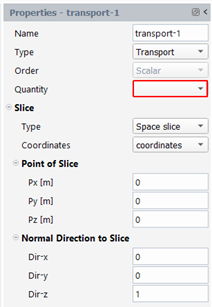

Transport

With this type of quantity, we will transport the value of a quantity along the whole pathline, the value being taken in a given slice (see figure below). The result quantity can be a scalar or a vector, depending on the order of the input quantity. Two kinds of slices may be defined: a slice on time (a time value and the time quantity must be specified) or a slice on space (a point and a normal to the cutting plane and the coordinates quantity must be specified).

In the property panel, select “Transport” for the Type, select the input quantity in the drop-down list “Quantity” and select the slice type:

If you selected a time slice, the property panel allows you to enter a time value and the time quantity, as shown below:

If you selected a space slice, the property panel allows you to enter a point of the slice, the normal direction to the slice and the coordinates quantity, as shown below:

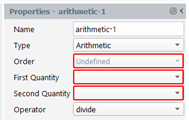

Arithmetic operations

We create a quantity that is the result of an arithmetic operation (addition, subtraction, multiplication, and division) between two quantities. The result quantity can be a scalar or a vector, depending on the order of the two quantities. Some combination of input quantities is not allowed depending on the selected operator: with the sum and subtraction, both quantities must have same order, with multiplication and division, the first quantity may be a scalar or a vector, but the second quantity must be a scalar. In the property panel, select “Arithmetic” for the Type, select the two quantities in the drop-down list “First Quantity” and “Second Quantity” respectively and select the operator:

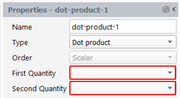

Dot Product

We create a quantity that is the dot product between two vector quantities. The result quantity is a scalar. In the property panel, select “Dot product” for the Type, select the two quantities in the drop-down list “First Quantity” and “Second Quantity” respectively:

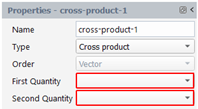

Cross Product

We create a quantity that is the cross product between two vector quantities. The result quantity is a vector. In the property panel, select “Cross product” for the Type, select the two quantities in the drop-down list “First Quantity” and “Second Quantity” respectively:

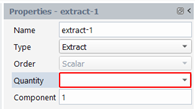

Extract

We create a quantity that is the i-th component of a vector quantity. The result quantity is a scalar. In the property panel, select “Extract” for the Type, select the input quantity in the drop-down list “Quantity” and select the component (1, 2 or 3):

For example, if the coordinates (x,y,z) is the selected quantity and the 2-nd component is chosen, then the extracted component will be y and it will be stored in the new quantity.

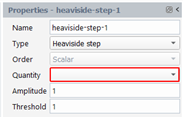

Heaviside step

We create a step quantity that is based on a scalar quantity. The result quantity is a scalar. For each instant of a pathline, we compare the local value V of the input quantity to a threshold value T: if V is greater than T, then the local value of the new quantity will be a given amplitude A, otherwise the local value of the new quantity will be zero. In the property panel, select “Heaviside step” for the Type, select the input quantity in the drop-down list “Quantity” and define the threshold and the amplitude:

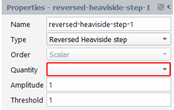

Reversed Heaviside step

We create a reversed step quantity that is based on a scalar quantity. The result quantity is a scalar. For each instant of a pathline, we compare the local value V of the input quantity to a threshold value T: if V is lower than T, then the local value of the new quantity will be a given amplitude A, otherwise the local value of the new quantity will be zero. In the property panel, select “Reversed Heaviside step” for the Type, select the input quantity in the drop-down list “Quantity” and define the threshold and the amplitude:

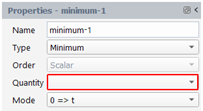

Minimum

We create a quantity that is based on a scalar quantity. The result quantity is a scalar. There are two modes for defining the minimum:

Mode "

": for each instant of a pathline, we compare the local value V of the input quantity to all previous values: the new value at that instant will be the minimum obtained:

Mode "

": for a pathline, we search the minimum of the local value V of the input quantity among all instants: the new value for all instants will be that minimum:

In the property panel, select “Minimum” for the Type, select the input quantity in the drop-down list “Quantity” and select the mode:

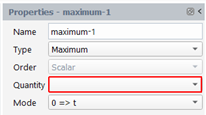

Maximum

We create a quantity that is based on a scalar quantity. The result quantity is a scalar. There are two modes for defining the maximum:

Mode "

": for each instant of a pathline, we compare the local value V of the input quantity to all previous values: the new value at that instant will be the maximum obtained:

Mode "

" : for a pathline, we search the maximum of the local value V of the input quantity among all instants: the new value for all instants will be that maximum:

In the property panel, select “Maximum” for the Type, select the input quantity in the drop-down list “Quantity” and select the mode:

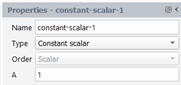

Constant Scalar

We create a quantity that is a scalar quantity. For each pathline, the local value of this new quantity will be the same for all instants. In the property panel, select “Constant scalar” for the Type, and define a constant value A:

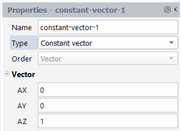

Constant vector

We create a quantity that is a vector quantity. For each pathline, the local vector of this new quantity will be the same for all instants. In the property panel, select “Constant vector” for the Type, and define the three components of the Vector (AX, AY, AZ):

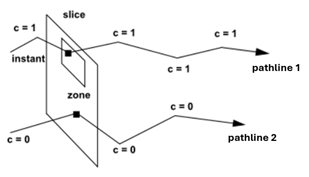

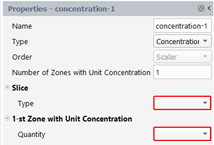

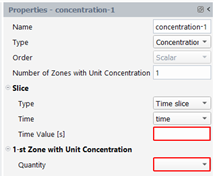

Concentration

With this type of quantity, we will transport a concentration value (0 or 1) along the whole pathline, the value being defined in a given slice (see figure below): the user specifies zones (for each zone, a quantity and bounds must be provided: if the value of the quantity in the slice is ranged in the bounds, then the local concentration will be one; if the instant i is out of the bounds of all zones, then the concentration will be zero). The user can define up to 5 zones. The result quantity is a scalar. Two kinds of slices may be defined: a slice on time (a time value and the time quantity must be specified) or a slice on space (a point and a normal to the cutting plane and the coordinates quantity must be specified).

Note that the concentration field is constant for a material point (no diffusion, no chemical reactions), the value of the concentration is transported along the trajectories without changing.

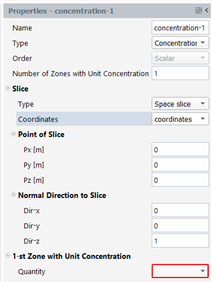

In the property panel, select “Concentration” for the Type, enter the number of zones and select the slice type:

If you selected a time slice, the property panel allows you to enter a time value and the time quantity, as shown below:

If you selected a space slice, the property panel allows you to enter a point of the slice, the normal direction to the slice and the coordinates quantity, as shown below:

Next, for each zone, specify the quantity and the bounds of the filter, as shown below:

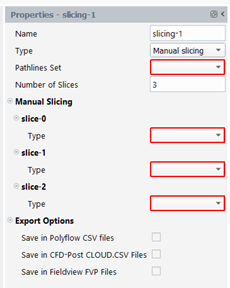

We specify here at which time or space interval we will cut the pathlines. Statistical functions will be later applied on each of those slices.

The list of available slicing types:

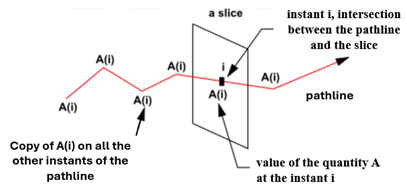

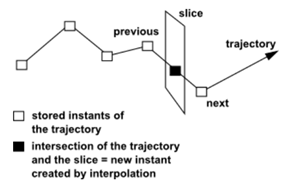

Remember that a pathline is a set of instants ordered in time. Each slice will contain a set of instants that are the intersections of the slice and the pathlines. If the intersection of a pathline and a slice is not a stored instant, a new instant is created by interpolation with the previous and the next instants that surround the intersection, as shown below:

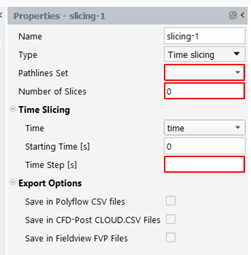

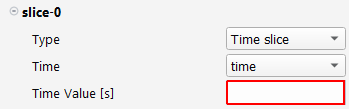

Time Slicing: with this kind of slicing, we cut the trajectories at regular time intervals. This kind of slicing should be used for flow fields in closed domain (e.g. batch mixers), where the process is time dependent. The user has to specify a pathlines set, a number of slices, a time quantity, a starting time ts and a time step dt.

The slices will be done at times: ts, ts+dt, ts+2dt, ..

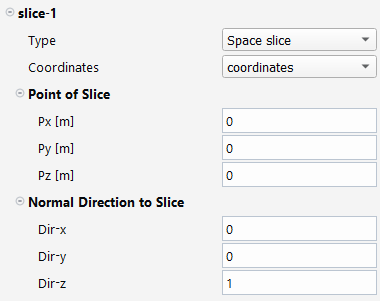

Space Slicing: with this kind of slicing, we cut the trajectories with planes at regular space intervals in a given direction. This kind of slicing should be used for flow fields in open domain (e.g. static mixers), where the process is steady state. The user has to specify a pathlines set, a number of slices, a coordinates quantity, a space step dl, a starting point ps and a normal direction to the slices N.

The successive planes contain point: ps, ps+dl * N, ps+2dl*N, .. and have normal N

Manual Slicing: with this kind of slicing, the user defines each slice one by one. By this way, slices are defined at precise location (in space or time), when it is not useful to get them at regular intervals. The user has to specify first a pathlines set and a number of slices n. When that number is specified a set of slices is visible in the property panel:

For each slice, the user will have to specify its type (Time slice or Space slice) and enter specific properties: a time quantity and a time value, if this is a time slice. While for a space slice, we need a coordinates quantity, a position of the cutting plane and a normal direction to the plane.

This kind of slicing is useful when the number of slices is small. Otherwise, it is rapidly cumbersome to enter numerous properties in a long panel.

The Export Options are always available: with these properties, one can export the set of slices for further analysis in other tools. Enable the outputs of interest:

Save in Polyflow CSV files: csv files are generated for analysis in Excel.

Save in CFD-Post CLOUD.CSV files: cloud.csv files are generated for visualization in CFD-Post.

Save in Fieldview FVP files: fvp files are generated for visualization in Fieldview.

All the files will be stored in the Statistics/Outputs directory under the project directory.

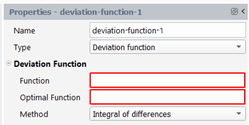

There are three kinds of functions available:

functions based on a pathlines set or a single pathline

functions based directly on the instants of slices

functions based on other functions

Different types are possible:

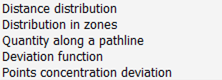

Quantity along a pathline :

The user has to specify a single pathline, a quantity to visualize and a time quantity.

The corresponding chart will present the time evolution of the given quantity for that pathline:

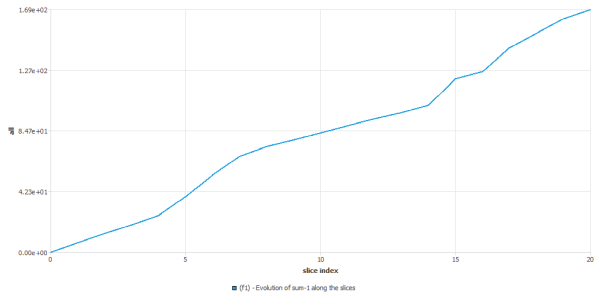

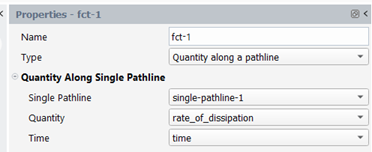

Sum

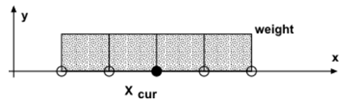

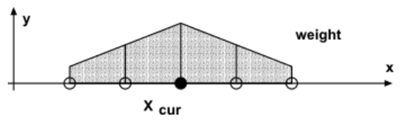

To calculate the sum function of a quantity, you need to specify which slicing to be used and to select a quantity. When the slicing type is a space slicing, the weight mode and a velocities quantity must be provided. Additional information on weighting is available in the annexes (§ on Weighting).

For each slice, we sum the value of the quantity of all the instants in the slice.

The corresponding chart will present the evolution of the sum of a quantity along the slices : the X axis is the slice index, and the Y axis is the quantity.

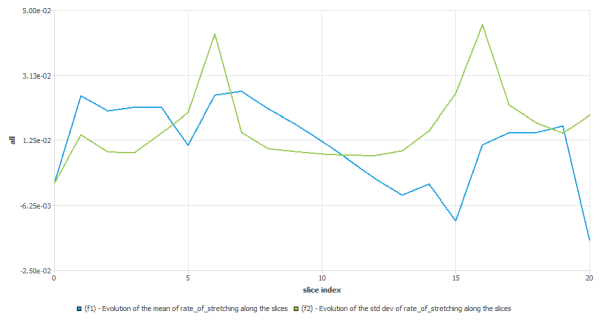

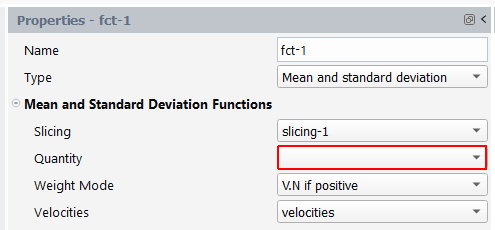

Mean and Standard Deviation

To calculate the mean and standard deviation functions of a quantity, you need to specify which slicing to be used and to select a quantity. When the slicing type is a space slicing, the weight mode and a velocities quantity must be provided. Additional information on weighting is available in the annexes (§ on Weighting).

The corresponding chart will present two curves: the evolution along the slices of the mean and of the standard deviation of a quantity : the X axis is the slice index, and the Y axis is the quantity .

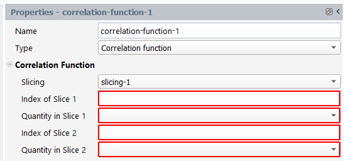

Correlation Function

To analyze a possible correlation between two quantities in two slices of the same slicing: select a slicing, and for that slicing, specify two slice indices and quantities.

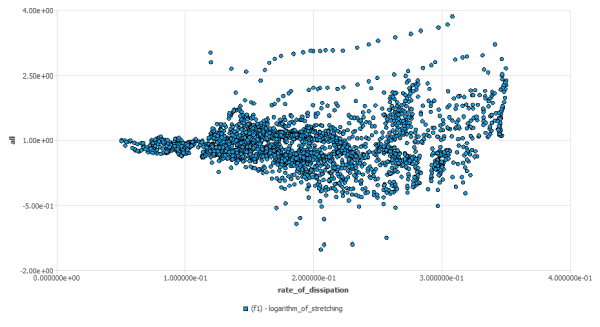

The corresponding chart will present on the X axis the quantity associated with the first slice, and on the Y axis the quantity associated with the second slice. Each dot of the plot corresponds to a pair { Quantity1(slice1); Quantity2(slice2) } of a virtual particle.

Note that the line type must be modified in the Plots page and set to “Point – Circle” (Dataset, … / Plot settings / set curve type).

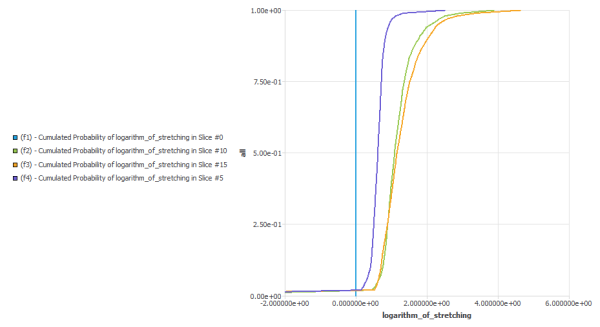

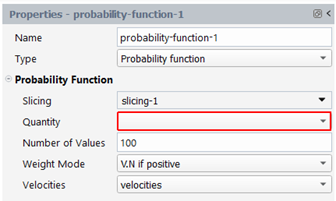

Probability function

To calculate the evolution of the probability function of a quantity, you need to specify a slicing, a quantity and the number of values to represent the curves (one evaluates one curve per slice). When the slicing type is a space slicing, the weight mode and a velocities quantity must be provided. Additional information on weighting is available in the annexes (§ on Weighting).

For a given slice, the probability is always ranged from 0 (for the minimum value of the quantity in the slice) to 1 (for the maximum value of the quantity in the slice).

If you visualize this function for a given slice, the quantity is on the X axis and the probability on the Y axis.

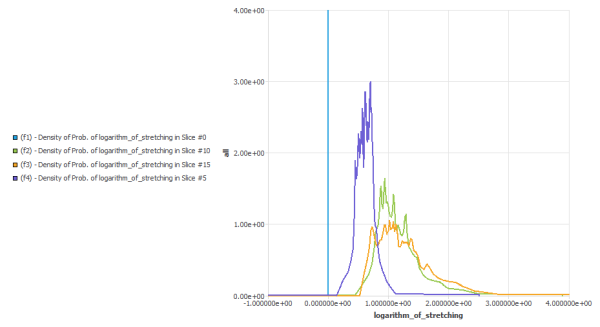

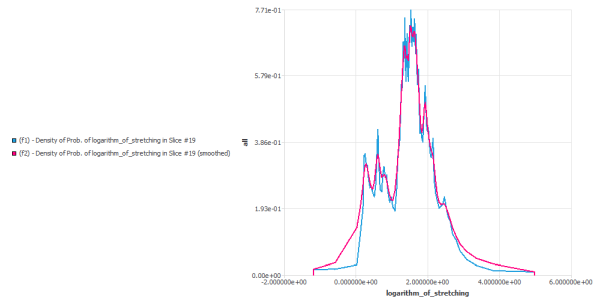

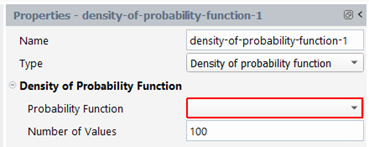

Density of Probability Function

To calculate the evolution of the density of probability function of a quantity, you need to specify a probability function (defined before) and the number of values to represent the curves (one evaluates one curve per slice): that number of values should be less than the number of values used to represent the probability function, in order to avoid too many wiggles: a good practice is to use half the number of values that represent the probability functions. If they persist, a smoothing on the density curves can be performed (see here after).

There is a list of probability functions P (one for each slice of a sorted list) and you obtain a density of probability function f for each slice S:

If you visualize this function for a given slice, the quantity is on the X axis and the density of probability on the Y axis.

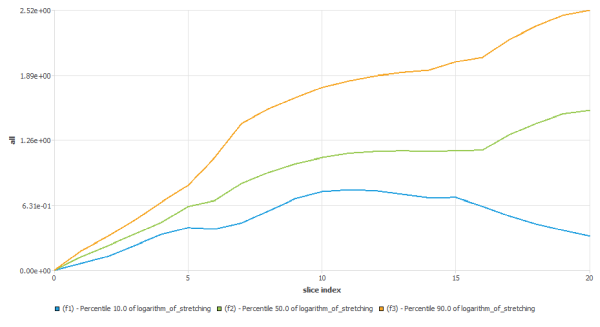

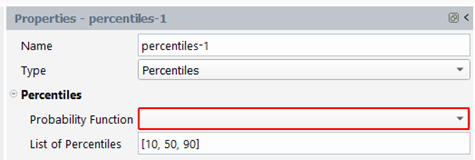

Percentiles

To calculate the evolution of percentiles of a quantity along slices, you need to specify a probability function (defined before) and a list of values (ranged from 0 to 100 %).

The corresponding chart will present a curve for each percentile: the evolution along the slices of the x-th percentile of a quantity : the X axis is the slice index, and the Y axis is the quantity ..

How to interpret such curves? For a given slice S, draw mentally a vertical line: that line will cut your percentiles (1Oth, 50th, 90th). Let note P10(S), P50(S) P90(S) the corresponding values obtained. The value of P10(S) indicates that in slice S, 10% of the instants have a value lower than P10(S) and 90% have a value higher than that value. The value of P50(S) indicates that in slice S, half the instants have a value lower than P50(S) and half have a value higher than that value. The value of P90(S) indicates that in slice S, 90% of the instants have a value lower than P90(S) and 10% have a value higher than that value.

So, in conclusion, P50 provide a similar information than the mean (but is not identical!!), and the distance between P10 and P90 provide similar information than the standard deviation (but is not identical!!).

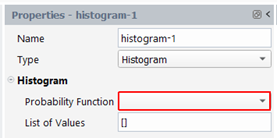

Histograms

To calculate the evolution of histograms of a quantity along slices, you need to specify a probability function (defined before) and a list of values to define the intervals of the histograms (ranged from the absolute minimum and absolute maximum of the quantity selected in the parent probability function.

From the list of probability functions (one for each slice of a sorted list), you obtain a histogram function for each slice. If you visualize this function for a given slice, the specified intervals of values (you chose the corresponding quantity when you defined the probability function) are on the X axis and the percentage of instants of the slice having a quantity value in each interval is on the Y axis.

Smoothing Function

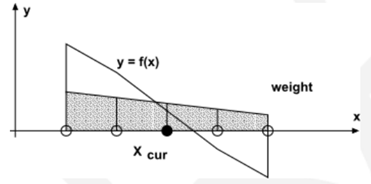

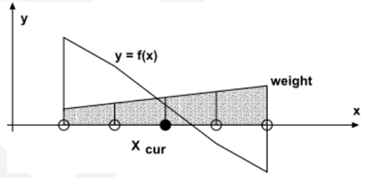

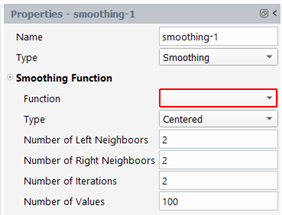

To create a smoothing function, you have to select the function to smooth and the type of smoothing : Equal, Centered (default), Upwind, Downwind. Moreover, some additional parameters are also required : number of left and right neighboors indicate how many neighbooring values are taken into account to update a given value. The number of iterations indicates how many times we re-do the smoothing. Eventually, we specify also the number of values to represent the smoothed function (a good practice is to use the same number of values that represent the data function).

Note that it is impossible to smooth a function that is already a smoothed function. The method of smoothing is as follows: to calculate one value of the result function, you calculate the mean of values that surround it in the data function. This process can be iterated several times. The calculation of the mean can be weighted in different ways (type of smoothing).

With Equal smoothing, the current Y-value and all its neighboors have the same weight.

With Centered smoothing, the current Y-value has the highest weight, and the weight decreases linearly as the distance to the current X-value increases.

With Upwind smoothing, first consider the Y-value of the farthest neighboor. The side with the highest Y-value is weighted more (to the left or the right side of the current X-value).

With Downwind smoothing, first consider the Y-value of the farthest neighboor. The side with the lowest Y-value is weighted more (to the left or the right side of the current X-value).

In the figure below, we see the effect of the smoothing on the density of probability of the ln(stretching), in a given slice: in blue the original curve, in red the smoothed curve.

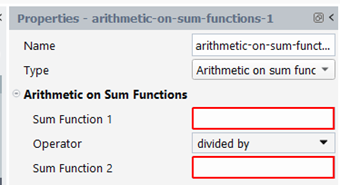

Arithmetic on Sum Functions

With this method, it is possible to combine two sum functions with an arithmetic operator (addition, multiplication, division and subtraction). Select the two sum functions, the operator.

The calculation is performed as follows: for a given slice index i (that assumes that the two sum functions have been evaluated on the same slicing), we take the corresponding values of the two sum functions F1( i ) and F2 ( i ) and we create a new function Y: the value of the result function for slice index i will be :

Y(i) = F1( i ) <operator> F2( i )

This function is useful to evaluate the global efficiency of stretching (see annexe for further details).

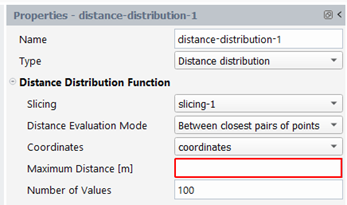

Distance Distribution

To calculate the evolution of the distribution function of distances between material points, you have to specify the slicing to be used, to select the coordinates quantity, to enter the number of values to represent the curves and to provide the maximum possible distance between pairs of points. Eventually, you have to choose between two modes of evaluation:

the first determines the distance distribution between all pairs of points. The maximum distance measured will be about the size of the flow domain, if the flow domain is closed.

the other determines the distance distribution only for pairs of points that are close neighboors (this is the default). The maximum distance measured, for a closed flow domain, will be

where V is the volume of the flow domain and n, the number of material points. The search of neighbouring points will be done only for distance between 0 and the value you specified. It is recommended that you choose a value greater than the maximum distance evaluated above.

For both modes: when evaluating the distance distribution for a given slice, we do not take into account pairs of points having a distance between them higher than this maximum.