The following limitations have been observed in the Fluent workflow:

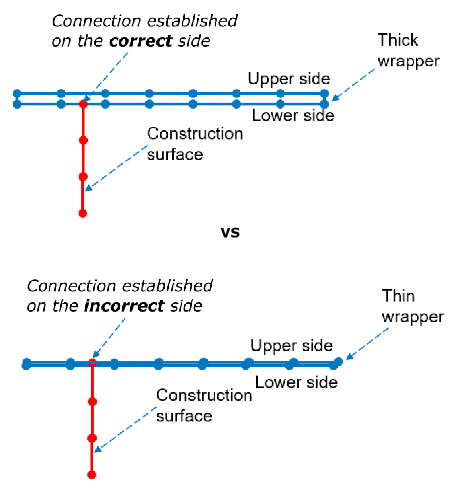

The workflow cannot properly connect construction surfaces to wrapped regions that are too thin.

In such cases, the wrapper faces between the upper and lower side are too close, and the construction surface connection may occur on the wrong side (the upper side rather than the lower side). For 3D cases, the improper connections can occur on the upper and/or lower sides, creating an incomplete intersected edge loop.

To ensure a smooth mesh everywhere in the domain, a growth rate applied locally in the domain will extend to the full domain, especially when the localized growth rate value is smaller than the global growth rate value.

Reverting and Editing Tasks That Use Existing Size Controls: When size controls are defined in the workflow using an existing size control file, if any of the intermediate checkpoint files are not available when reverting and editing any of the size-control tasks, the execution of the overall workflow may lead to additional unwanted task updates. To avoid this issue, you can use default size-controls when possible, or you can create the intermediate checkpoint files by saving the workflow template, loading the template back into a new session, and then updating the tasks.

Import CAD and Part Management

On Windows and Linux, you cannot import multiple CAD files that contain different units into the same workflow.

Before importing SpaceClaim files (

.scdocand.scdocx) into Fluent Meshing, you need to first enable the license preference option in SpaceClaim in order to uphold licensing preferences.When importing CAD files, the naming convention for CAD parts can not contain the

\character.The import of 2D models is not supported.

When importing JT CAD data, the JTOpen option is available on more recent Linux OS variants (requiring a

glibcsupplying'memcpy@GLIBC_2.14'), that is, it is not supported on Red Hat / CentOS 6 series.When importing CAD data via the Workbench route on Linux, the SLES 15 platform is not supported.

Importing polyhedra and poly-hexcore mesh files is not supported.

Importing CAD files is not supported when using remote Linux nodes from Windows.

Generate the Surface Mesh

The workflow does not support adding zone-specific settings (such as boundary layers) outside the workflow. You can, however, set up zone-specific boundary layers within the workflow using the Add Boundary Layers task.

Add Boundary Layers

The workflow does not support adding boundary layers in solid regions.

Generate the Volume Mesh

You should avoid scenarios where, for a fixed total initial boundary layer height, a specified growth rate will never be respected for a large number (~!00) of splits. Such a scenario results in the first heights of the boundary layer being too small (~1e-16) and introduces system limitations that should be avoided.

Extrude Volume Mesh

The preview box is available only for selected faces whose normal is aligned with the Cartesian coordinate.

Extruding cylindrical surfaces too far may create invalid meshes. If your cylindrical surface extrusion exhibits undesirable skewness or otherwise is invalid, reduce the total height of the extrusion and perform the operation again to see if results improve.

Create Collar Mesh

When creating the collar mesh, you should only use the Automatic option to preview the location of the collar mesh, but you should use the Numerical Inputs option to define the actual location.

Preferences

The workflow does not fully support the Write into memory option, so if selected as a preference, the workflow will use Write mesh files instead. See Setting Preferences for Workflows for more information about preferences in saving data for editing tasks.

Limitations for Using the Poly Hexcore Volume Fill Method in Parallel

The mesh quality may not be perfect, due to a few invalid cells, and the change in size could be large for a few cells in the poly transition area.