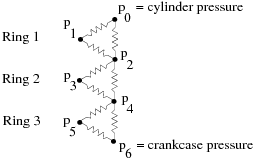

The crevice model implemented in Ansys Fluent is a zero-dimensional ring-flow model based on the model outlined in Namazian and Heywood [470] and Roberts and Matthews [558]. The model is geared toward in-cylinder specific flows, and more specifically, direct-injection (DI) diesel engines, and therefore is available only for time-dependent simulations.

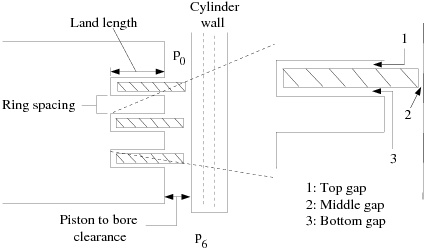

The model takes mass, momentum, and energy from cells adjoining two boundaries and accounts for the storage of mass in the volumes of the crevices in the piston. Detailed geometric information regarding the ring and piston—typically a ring pack around the bore of an engine—is necessary to use the crevice model. An example representation is shown in Figure 10.3: Crevice Model Geometry (Piston) — Figure 10.5: Crevice Model “Network” Representation.

The piston to bore clearance is the distance between the piston and the bore. Typical values are 2 to 5 mil (80 to 120 μm) in a spark engine (SI) and 4 to 7 mil (100 to 240 μm) in some diesel engines (DI).

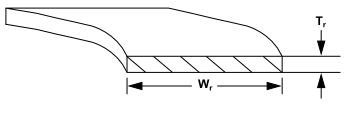

The ring thickness is the variable

in Figure 10.4: Crevice Model Geometry (Ring). Typical values range from 1 to 3 mm for SI engines and 2 to 4 mm for DI engines.

The ring width is the variable

in Figure 10.4: Crevice Model Geometry (Ring). Typical values range from 3 to 3.5 mm for SI engines and 4 to 6 mm for DI diesel engines.

The ring spacing is the distance between the bottom of one ring land and the top of the next ring land. Typical values of the ring spacing are 3 to 5 mm for SI engines and 4 to 8 mm for DI diesel engines.

The land length is the depth of the ring land (that is, the cutout into the piston); always deeper than the width of the ring by about 1 mm. Typical values are 4 to 4.5 mm for SI engines and 5 to 7 mm for DI diesel engines.

The top gap is the clearance between the ring land and the top of the ring (40 to 80 μm).

The middle gap is the distance between the ring and the bore (10 to 40 μm).

The bottom gap is the clearance between the ring land and the bottom of the ring (40 to 80 μm).

The shared boundary and leaking wall is the piston (for example,

wall-8) and the cylinder wall (for example,wall.1) in most in-cylinder simulations. Cells that share a boundary with the top of the piston and the cylinder wall are defined as the crevice cells.

The ring pack is the set of rings that seal the piston in the cylinder bore. As the piston moves upward in the cylinder when the valves are closed (for example, during the compression stroke in a four-stroke cycle engine), the pressure in the cylinder rises and flow begins to move past the rings. The pressure distribution in the ring pack is modeled by assuming either fully-developed compressible flow through the spaces between the rings and the piston, or choked compressible flow between the rings and the cylinder wall.

Since the temperature in the ring pack is fixed and the geometry is known, once a pressure distribution is calculated, the mass in each volume can be found using the ideal gas equation of state. The overall mass flow out of the ring pack (that is, the flow past the last ring specified) is also calculated at each discrete step in the Ansys Fluent solution.