VMFLGPU007

VMFLGPU007

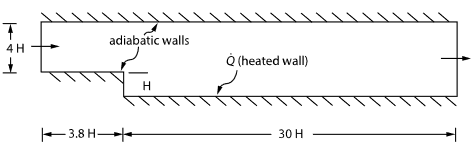

Turbulent Flow with Heat Transfer in a Backward-Facing Step

Overview

| Reference |

J.C. Vogel, J.K. Eaton, "Combined Heat Transfer and Fluid Dynamic Measurements Downstream of a Backward-Facing Step". Journal of Heat Transfer, Vol. 107, pp. 922-929, 1985. |

| Solver | Ansys Fluent GPU |

| Physics/Models |

Incompressible, turbulent flow with heat convection and reattachment. |

| Input File |

vt007.msh,vmfl007.jou

|

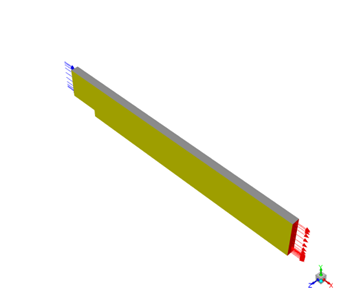

Test Case

Airflow over a Goldman stator blade at the mid-span is considered. This 2.5D analysis provides insight into Ansys Fluent's ability to predict the complicated flow features typical of turbomachinery applications. The geometry of the domain under consideration is shown in the figure below. The inlet and the outlet are located approximately 0.03 m away from the blade's leading and trailing edges, respectively. They are located where their presence does not affect predictions near the blade.

| Material Properties | Geometry | Boundary Conditions |

|---|---|---|

|

Density = 1 kg/m3 Viscosity = 0.0001 kg/m-s Conductivity = 1.408 W/m-K Specific Heat = 10,000 J/kg-K |

H = 1m |

I Velocity profile at inlet corresponding to ReH = 28,000 Wall heat transfer, Q˙= 1,000 W/m2 |

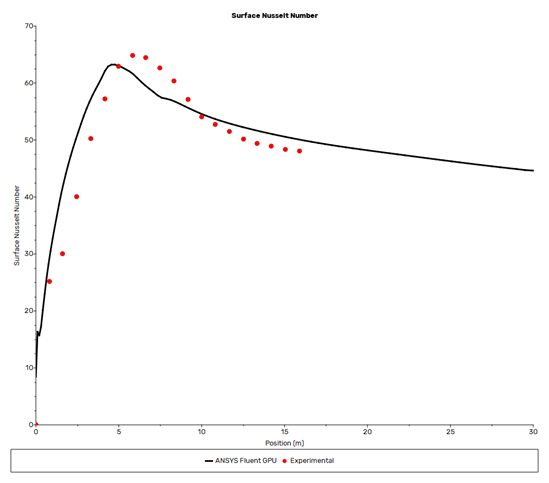

Analysis Assumptions and Modeling Notes

The flow is steady and incompressible. Fluid properties are considered constant. Pressure based solver is used. The inlet boundary conditions are specified using the fully developed profiles for the velocity, k, and epsilon. The incoming boundary layer thickness is 1.1 H. Under the given pressure conditions, the Reynolds number, ReH is about 28,000 The standard k-ε model with standard wall functions is used for accounting turbulence.