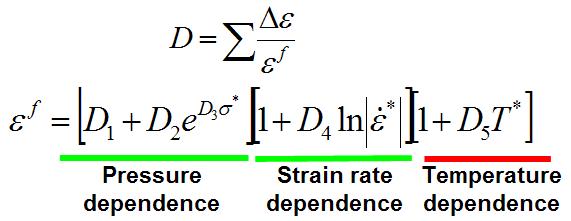

The Johnson-Cook failure model can be used to model ductile failure of materials experiencing large pressures, strain rates and temperatures.

This model is constructed in a similar way to the Johnson-Cook plasticity model in that it consists of three independent terms that define the dynamic fracture strain as a function of pressure, strain rate and temperature:

is the dimensionless pressure-pressure stress ratio =

, where

is the mean stress and

is the effective stress or von Mises equivalent stress.

The ratio of the incremental effective plastic strain and effective fracture strain for the element conditions is incremented and stored in custom results variable, DAMAGE. The material is assumed to be intact until DAMAGE = 1.0. At this point failure is initiated in the element. An instantaneous post failure response is used.

Note: The property can only be applied to solid bodies.

Table 11.22: Input Data

| Name | Symbol | Units | Notes |

|---|---|---|---|

| Damage Constant D1 | D1 | None | |

| Damage Constant D2 | D2 | None | |

| Damage Constant D3 | D3 | None | |

| Damage Constant D4 | D4 | None | |

| Damage Constant D5 | D5 | None | |

| Melting Temperature | Temperature |

Custom results variables available for this model:

| Name | Description | Solids | Shells | Beams |

|---|---|---|---|---|

| DAMAGE | Damage | Yes | No | No |

**Material status indicators (1 = elastic, 2 = plastic, 3 = bulk failure, 4= bulk failure, 5 = failed principal direction1, 6 = failed principal direction 2, 7 = failed principal direction 3)