The tensile crack softening model is fracture energy based damage model which can be used with many different types of failure initiation models to provide a gradual reduction in the ability of an element to carry tensile stress. The model is primarily used for investigating failure of brittle materials, but has been applied to other materials to reduce mesh dependency effects.

Failure initiation is based on any of the standard tensile failure models; for example, Hydro, Principal Stress/Strain

On failure initiation, the current maximum principal tensile stress in the element is stored (custom result FAIL.STRES)

A linear softening slope (custom result SOFT.SLOPE) is then defined to reduce the maximum possible principal tensile stress in the material as a function of crack strain. This softening slope is defined as a function of the local element size and a material parameter, the fracture energy Gf.

The extent of damage in a material can be inspected by using the custom result DAMAGE. The damage is defined to be 0.0 for an intact element and 1.0 for a fully failed element.

After failure initiation, a maximum principal tensile stress failure surface is defined to limit the maximum principal tensile stress in the element and a flow rule is used to return to this surface and accumulate the crack strain

There are currently three options in relation to the crack softening plastic return algorithm:

Radial Return — Non-associative in π– and meridian planes

No-Bulking — Associative in π– plane only (Default)

Bulking — Associative in π– and meridian planes

The default setting has been selected based on practical experiences of using the model to simulate impacts onto brittle materials such as glass, ceramics, and concrete.

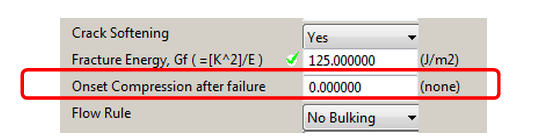

The recompression behavior after crack softening and failure can be modified. When one of the failure criteria (for instance principal stress, hydro (Pmin), or RHT concrete) has been set and Crack Softening is set to Yes, the Onset Compression after failure option can be used to change the compression criterion at which pressure can build up again in failed elements.

The effects of different values in this field are as follows:

Onset compression = 0.0 (default) — Pressure can only build up if the material is in compression.

Onset compression < 0 — For large negative values, the material will be able to immediately build up pressure after tensional failure when fractured material resists compression. For real-world applications, you should determine a value for this field which is less than or equal to zero and appropriate for the material in the analysis.

The crack softening algorithm can only be used with solid elements. It can be used in combination with any solid equation of state, plasticity model or brittle strength model.

When used in conjunction with a plasticity/brittle strength model, the return algorithm will return to the surface giving the minimum resulting effective stress, J2.

Meridian Plane

π- space

Note: The property can only be applied to solid bodies.

Table 11.21: Input Data

| Name | Symbol | Units | Notes |

|---|---|---|---|

| Fracture Energy | Gf | Energy/Area | |

| Flow rule | Option List: Radial Return No Bulking (Default) Bulking (Associative) |

Custom results variables available for this model:

| Name | Description | Solids | Shells | Beams |

|---|---|---|---|---|

| DAMAGE | Current damage level | Yes | No | No |

| FAIL.STRES | Principal tensile failure stress | Yes | No | No |

| SOFT.SLOPE | Softening slope | Yes | No | No |