STL & OP2

Both the EnSight STL and Nastran OP2 formats, in addition to reading the native formats directly (.stl and .op2, respectively), each include the ability to read a customized variant case file that contains a list of native format files and the associated EnSight Euler format filename. The STL reader calls this an exec file (.xct), see the STL Reader section for details. The Nastran OP2 calls this case file a MOP file (.mop). This "executive file" (.stl or .mop) allows either reader to handle multiple native files simultaneously, as well as optionally allowing them to be transformed by one or more rigid body Euler files.

Note: The rigid body transformations in the Euler file must be created outside the STL format, and outside of the Nastran solver.

Abaqus ODB Analytical Rigid Surfaces

ABAQUS has a concept of rigid surfaces that do not have elements and are modeled only analytically as extruded or rotated surfaces (plates or cylinders) that move as rigid, non deformable bodies over time according to transformations in the .odb data file. The ABAQUS ODB reader creates these rigid entities first as lines using EnSight line elements in the User Defined Reader API (which can be extruded in a separate operation in EnSight into surfaces). These lines will translate and rotate according to the parameters in the .odb file. You can then manually use the EnSight Extrude option or can use a python tool included with EnSight to properly extrude these line parts into cylindrical or planar surfaces according to their design (for details, see the ABAQUS reader section).

Fluent and Star Export Case Gold

For data with part(s) rotating at a steady state, both Fluent and Star export this data as a steady state geometry with an assigned rotational rate value. Their native post-processors, which are aware of this, can then reproduce the transient orientation of the fan at any given time. A pseudo transient state is created from steady state files. This allows the geometry to be written out only once, but the transient orientation of the fan can be reproduced at any arbitrary level of fineness of time in the native post-processor.

Unfortunately, when users export their data from the solver into EnSight Case Gold, this native awareness is lost. The pseudo transient state does not exist to update the fan's transient orientation in time. Therefore you can have effects like streamline traces which impact the non-moving fan and just stop. Some effort is required to reproduce the effects of the native solver post-processor in this case. Basically, rigid body can be used. EnSight Rigid Body and Euler Parameter files must be created and referenced in an updated Case Gold file, and the pathline trace option should be used instead of streamline traces.

If your solution has been solved in an implicitly rotating reference frame, and you want to either visualize the motion, or correctly produce particle traces through the domain, then you will need to utilize both EnSight Case Gold Format files, as well as utilizing the Rigid Body Tool (Click the toolbox icon at the top and open Visualize → Rigid Body Motion). This will generate both of the two rigid body files as well as modify the case file to reference the new information. Two critical decisions you must make when running the tool are

number of steps, and

total time to rotate

The number of steps chosen should be small enough to reflect the courant number of the grid + velocity so that the change between timesteps maintains reasonable changes in grid location and velocity values so that continuous pathline integration is numerically accurate. Choosing too small of a timestep will slow the calculation and animation time, while too large of a timestep will result in errors in pathline calculation. Models with either higher rotational speeds, finer grids, or higher velocity regions should be setup with small timesteps. The Total Time should be chosen so that you have rotated one repeatable sector, given the rotational speed (fixed, and specified), and the number of steps.

Since the rotation is cyclical, only one repeatable increment in fan rotation is necessary, and then EnSight can cyclically repeat that increment N number of times as below, to allow the relatively low speed upstream flow sufficient number of fan blade cycles to reach to the relatively high speed fan blade and pass through successfully.

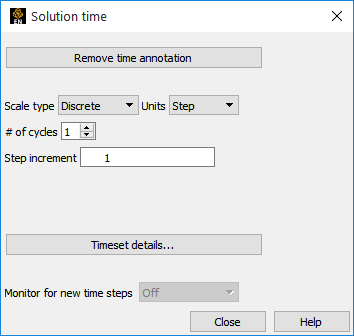

To repeat a time series for N cycles:

Click on the more button on the time controls.

Change the number of cycles.