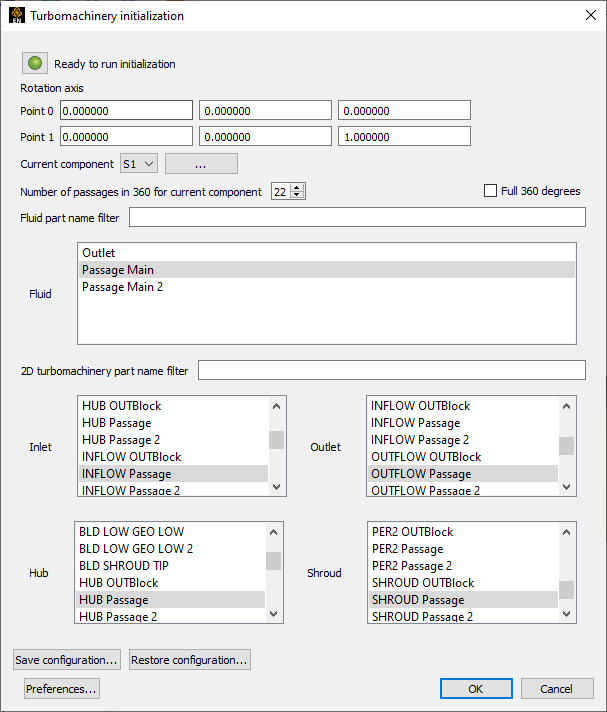

Load the model. Launch via the menu. A message at the top of the Turbomachinery initialization dialog will warn you about the initialization not being performed yet. Click on the button to open the Initialization menu.

You will find below the information that needs to be entered to perform the initialization:

Rotation axis: Point 0 and Point 1. Enter the X,Y,Z coordinates for two points that determine the rotation axis. By default, these will be (0, 0, 0) and the Z direction.

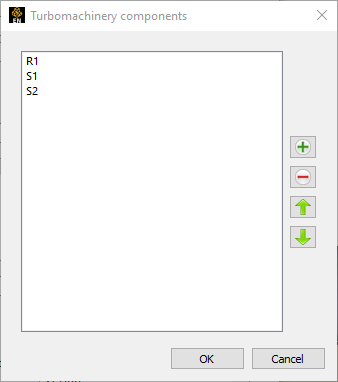

Current component: Click on the button next to Current component. This will pop up a new dialog that contains the list of components. Add / delete components using the plus or minus button. Change a component name by double-clicking its name. Change the order of the components using the arrows for the components to be sorted from downstream to upstream. See Figure : Turbomachinery Components Dialog.

Once all the components have been set correctly, use the pull down menu to select each component individually and enter its initialization parameters.

Below are the initialization parameters for each component:

Number of passages in 360 for current component: This can be different for each component. It must be an integer number that represents how many times the model needs to be repeated in a rotational symmetry to fully represent a 360 degrees geometry.

If the model represents the full 360 degree of the simulation (for example, Number of passages in 360 for current component would be 1), then simply check the toggle. This will gray out Number of passages in 360 for current component.

Note: While this step is not needed to make the turbomachinery workflow work, it will provide a better performance.

Select one or more parts from the list of 3D parts in the Fluid box.

Select one or more parts for each of the turbomachinery types: Inlet, Outlet, Hub and Shroud.

Once all of these parameters are set for all components, click to run the initialization. If you selected multiple parts for the Inlet, Outlet, Hub and Shroud for a specific component, there will now be an extra part in the part list that represents the merging of these parts. EnSight is now ready to perform ther Turbomachinery analysis.