Note: The information provided in this manual describes two special reactor models that are included with Ansys Chemkin.

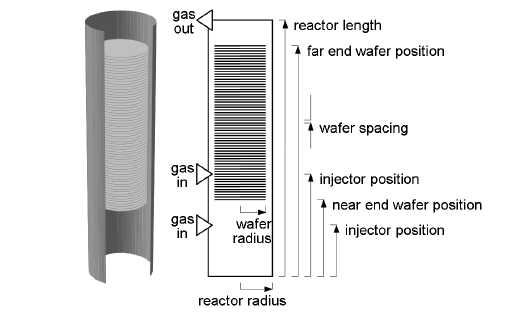

Chemical vapor deposition ( CVD) is a chemical process used for the deposition of thin films in the semiconductor and related materials industries. A common design used for the deposition of such films is the multi-wafer low-pressure batch furnace, shown schematically in Figure 1.1: Schematic of a Multiwafer LPCVD Reactor, with the Important Dimensions Indicated. In these reactors, up to several hundred silicon wafers are stacked concentrically and processed in a single batch run. These low-pressure CVD (LPCVD) reactors are thus well suited to large-scale wafer production. Originally, these "workhorses" of the silicon microelectronics industry had horizontal racks of wafers, but modern tools have a vertical orientation that reduces the "footprint" of the reactor on the factory floor.

Computer simulation is an important tool in the development of equipment and processes for CVD. The Ansys Chemkin LPCVD Furnace Model and Thermal Analyzer provide accurate simulation of these multi-wafer LPCVD reactors, allowing users to specify the process chemistry, reactor dimensions, flow rates, pressures, temperatures, wafer quantities and wafer sizes. The original derivation of the Furnace Model governing equations has been described by Houf, et al. [1] Based on this work, the Chemkin LPCVD Furnace Model and Thermal Analyzer treat a cylindrically symmetric reactor tube and large numbers of evenly spaced wafers operating at relatively low pressures.

The LPCVD Thermal Analyzer performs a detailed heat-transfer analysis of the batch-furnace geometry, including user-specified radiant lamp locations and estimation of thermocouple measurements under a given set of operating conditions, which can be transient or steady-state. As a result, the LPCVD Thermal Analyzer predicts a temperature map of the furnace, indicating temperature uniformity across the load and along each wafer. This temperature profile information can then be used as input to the LPCVD Furnace Model. The LPCVD Furnace Model includes detailed gas and surface kinetics to predict the film deposition uniformity for the wafers and the wafer stack. The LPCVD Furnace Model can also be used independently of the LPCVD Thermal Analyzer using a known or uniform temperature profile.