This tutorial includes:

In this tutorial you will learn about:

Setting up a transient problem in CFX-Pre.

Using an opening type boundary in CFX-Pre.

Making use of multiple configurations in CFX-Pre

Modeling smoke using additional variables in CFX-Pre.

Visualizing a smoke plume using an isosurface in CFD-Post.

Creating an image for printing, and generating a movie in CFD-Post.

Component | Feature | Details |

|---|---|---|

CFX-Pre | User Mode | General mode |

Analysis Type | Steady State | |

Transient | ||

Fluid Type | General Fluid | |

Domain Type | Single Domain | |

Turbulence Model | k-Epsilon | |

Boundary Conditions | Inlet (Subsonic) | |

Opening | ||

Wall: No-Slip | ||

Timestep | Auto Time Scale | |

Transient Example | ||

Configuration | Multiple | |

Transient Results File | ||

CFD-Post | Plots | Animation |

Isosurface | ||

Other | Auto Annotation | |

Movie Generation | ||

Printing | ||

Time Step Selection | ||

Title/Text | ||

Transient Animation |

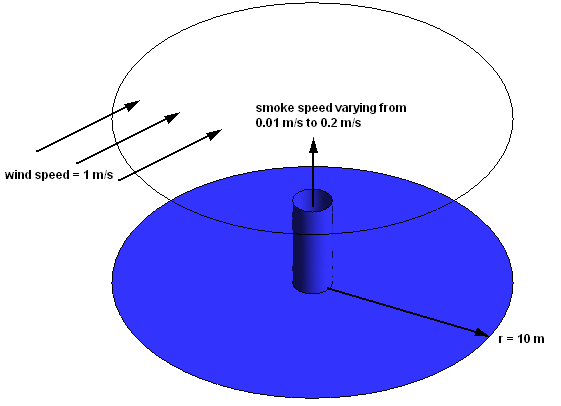

In this example, a chimney stack releases smoke that is dispersed into the atmosphere with an oncoming side wind of 1 m/s. The turbulence will be set to intensity and length scale with a value of 0.05, which corresponds to 5% turbulence, a medium level intensity, and with an eddy length scale value of 0.25 m. The goal of this tutorial is to model the dispersion of the smoke from the chimney stack over time. Unlike previous tutorials, which were steady-state, this example is time-dependent. Initially, no smoke is being released. Subsequently, the chimney starts to release smoke. As a postprocessing exercise, you produce an animation that illustrates how the plume of smoke develops with time.

If this is the first tutorial you are working with, it is important to review the following topics before beginning:

Create a working directory.

Ansys CFX uses a working directory as the default location for loading and saving files for a particular session or project.

Download the

circvent.zipfile here .Unzip

circvent.zipto your working directory.Ensure that the following tutorial input file is in your working directory:

CircVentMesh.gtm

Set the working directory and start CFX-Pre.

For details, see Setting the Working Directory and Starting Ansys CFX in Stand-alone Mode.

This section describes the step-by-step definition of the flow physics in CFX-Pre for a simulation with two analyses. First is a steady-state analysis with no smoke being produced by the chimney. The second analysis takes the setup for the steady-state and adapts it for a transient analysis. The results from the steady-state analysis will be used as the initial guess for the transient analysis.

In CFX-Pre, select File > New Case.

Select General and click .

Select File > Save Case As.

Set File name to

CircVent.Click .

Right-click

Meshand select Import Mesh > CFX Mesh.The Import Mesh dialog box appears.

Configure the following setting(s):

Setting

Value

File name

CircVentMesh.gtm

Click Open.

Right-click a blank area in the viewer and select Predefined Camera > Isometric View (Z up) from the shortcut menu.

In this tutorial an Additional Variable (non-reacting scalar component) will be used to model the dispersion of smoke from the vent.

Note: While smoke is not required for the steady-state simulation, including it here prevents you from having to set up time value interpolation in the transient analysis.

From the menu bar, select Insert > Expressions, Functions and Variables > Additional Variable.

Set Name to

smoke.Click .

Set Variable Type to

Volumetric.Set Units to

[kg m^-3].Click .

The existing analysis will be set up as steady-state.

To rename the existing analysis:

From the Outline tree, right-click

Simulation>Flow Analysis 1and click Rename.Rename the analysis to

Steady State Analysis.

You will create a fluid domain that includes support for smoke as an Additional Variable.

Select Insert > Domain from the menu bar, or click Domain

,

then set the name to

,

then set the name to CircVentand click .Configure the following setting(s):

Tab

Setting

Value

Basic Settings

Location and Type

> Location

B1.P3

Fluid and Particle Definitions

Fluid 1

Fluid and Particle Definitions

> Fluid 1

> Material

Air at 25 C

Domain Models

> Pressure

> Reference Pressure

0 [atm]

Fluid Models Heat Transfer

> Option

None

Turbulence

> Option

k-Epsilon

Additional Variable Models

> Additional Variable

smoke

Additional Variable Models

> Additional Variable

> smoke

(Selected)

Additional Variable Models

> Additional Variable

> smoke

> Kinematic Diffusivity

(Selected)

Additional Variable Models

> Additional Variable

> smoke

> Kinematic Diffusivity

> Kinematic Diffusivity

1.0E-5 [m^2 s^-1] [a]

Click .

This is an example of external flow, since fluid is flowing over an object and not through an enclosure such as a pipe network (which would be an example of internal flow). In external flow problems, some inlets will be made sufficiently large that they do not affect the CFD solution. However, the length scale values produced by the Default Intensity and AutoCompute Length Scale option for turbulence are based on inlet size. They are appropriate for internal flow problems and particularly, cylindrical pipes. In general, you need to set the turbulence intensity and length scale explicitly for large inlets in external flow problems. If you do not have a value for the length scale, you can use a length scale based on a typical length of the object over which the fluid is flowing. In this case, you will choose a turbulence length scale that is one-tenth of the diameter of the vent.

For parts of the boundary where the flow direction changes, or is unknown, an opening boundary can be used. An opening boundary allows flow to both enter and leave the fluid domain during the course of the analysis.

You will create the inlet boundary with velocity components set consistently with the problem description.

Select Insert > Boundary from the menu bar or click Boundary

.

.Set Name to

Wind.Click .

Configure the following setting(s):

Tab

Setting

Value

Basic Settings

Boundary Type

Inlet

Location

Wind

Boundary Details

Mass And Momentum

> Option

Cart. Vel. Components

Mass and Momentum

> U

1 [m s^-1]

Mass and Momentum

> V

0 [m s^-1]

Mass and Momentum

> W

0 [m s^-1]

Turbulence

> Option

Intensity and Length Scale

Turbulence

> Fractional Intensity

0.05 [a]

Turbulence

> Eddy Length Scale

0.25 [m] [a]

Additional Variables

> smoke

Value

Additional Variables

> smoke

> Add. Var. Value

0 [kg m^-3] [b]

Click .

Note: The boundary marker vectors used to display boundary conditions (inlets, outlets, openings) are normal to the boundary surface regardless of the actual direction specification. To plot vectors in the direction of flow, select Boundary Vector under the Plot Options tab for the inlet boundary, and on the Labels and Markers Options tab (accessible from Case Options > Labels and Markers on the Outline tree view), ensure that Settings > Show Boundary Markers is selected and Show Inlet Markers is cleared.

You will create an opening boundary with pressure and flow direction specified. If fluid enters the domain through the opening, it should have turbulence intensity and length scale, as well as smoke concentration, set to the same values as for the inlet.

Select Insert > Boundary from the menu bar or click Boundary

.

.Set Name to

Atmosphere.Click .

Configure the following setting(s):

Tab

Setting

Value

Basic Settings

Boundary Type

Opening

Location

Atmosphere

Boundary Details

Mass And Momentum

> Option

Opening Pres. and Dirn

Mass and Momentum

> Relative Pressure

0 [Pa]

Flow Direction

> Option

Normal to Boundary Condition

Turbulence

> Option

Intensity and Length Scale

Turbulence

> Fractional Intensity

0.05

Turbulence

> Eddy Length Scale

0.25 [m]

Additional Variables

> smoke

> Option

Value

Additional Variables

> smoke

> Add. Var. Value

0 [kg m^-3]

Click .

You will create the vent inlet boundary with a normal velocity of 0.01 m/s as prescribed in the problem description and no smoke release. The turbulence level for the inlet vent will be determined from turbulence intensity and eddy viscosity ratio.

Select Insert > Boundary from the menu bar or click Boundary

.

.Set Name to

Vent.Click .

Configure the following setting(s):

Tab

Setting

Value

Basic Settings

Boundary Type

Inlet

Location

Vent

Boundary Details

Mass And Momentum

> Normal Speed

0.01 [m s^-1]

Turbulence

> Option

Intensity and Eddy Viscosity Ratio

Turbulence

> Fractional Intensity

0.05

Turbulence

> Eddy Viscosity Ratio

10

Additional Variables

> smoke

> Option

Value

Additional Variables

> smoke

> Add. Var. Value

0 [kg m^-3]

Click .

For this tutorial, the automatic initial values are suitable. Review and apply the default settings:

Click Global Initialization

.

.Review the settings for velocity, pressure, turbulence and the smoke.

Click .

CFX-Solver has the ability to calculate physical time step size

for steady-state problems. If you do not know the time step size to

set for your problem, you can use the Auto Timescale option.

Click Solver Control

.

.Configure the following setting(s):

Tab

Setting

Value

Basic Settings

Convergence Control

> Max. Iterations

75

Note that Convergence Control > Fluid Timescale Control > Timescale Control is set to

Auto Timescale.Click .

In this part of the tutorial, you will duplicate the steady-state analysis and adapt it to set up a transient flow analysis in CFX-Pre.

In the Outline tree view, right-click

Simulation>Steady State Analysisand select Duplicate.Right-click

Simulation>Copy of Steady State Analysisand select Rename.Rename the analysis to

Transient Analysis.

In this step you will set the new analysis to a type of transient. Later, you will set the concentration of smoke for the transient analysis to rise asymptotically to its final concentration with time, so it is necessary to ensure that the interval between the time steps is smaller at the beginning of the simulation than at the end.

In the Outline tree view, ensure that

Simulation>Transient Analysisis expanded.Right-click

Simulation>Transient Analysis>Analysis Typeand select Edit.Configure the following setting(s):

Tab

Setting

Value

Basic Settings

Analysis Type

> Option

Transient

Analysis Type

> Time Duration

> Option

Total Time

Analysis Type

> Time Duration

> Total Time

30 [s]

Analysis Type

> Time Steps

> Timesteps

4*0.25, 2*0.5, 2*1.0, 13*2.0 [s] [a]

Analysis Type

> Initial Time

> Option

Automatic with Value

Analysis Type

> Initial Time

> Time

0 [s]

Click .

The only boundary condition that needs altering for the transient

analysis is the Vent boundary condition. In the

steady-state calculation, this boundary had a small amount of air

flowing through it. In the transient calculation, more air passes

through the vent and there is a time-dependent concentration of smoke

in the air. This is initially zero, but builds up to a larger value.

The smoke concentration will be specified using the CFX Expression

Language.

In the Outline tree view, ensure that

Simulation>Transient Analysis>CircVentis expanded.Right-click

Simulation>Transient Analysis>CircVent>Ventand select Edit.Configure the following setting(s):

Tab

Setting

Value

Boundary Details

Mass And Momentum

> Normal Speed

0.2 [m s^-1]

Leave the Vent details view open for now.

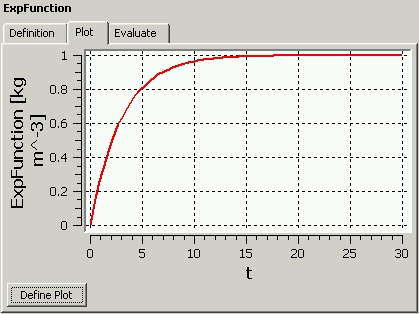

You are going to create an expression for smoke concentration. The concentration is zero for time t=0 and builds up to a maximum of 1 kg m^-3.

Create a new expression by selecting Insert > Expressions, Functions and Variables > Expression from the menu bar. Set the name to

TimeConstant.Configure the following setting(s):

Name

Definition

TimeConstant

3 [s]

Click to create the expression.

Create the following expressions with specific settings, remembering to click after each is defined:

Name

Definition

FinalConcentration

1 [kg m^-3]

ExpFunction

FinalConcentration*abs(1-exp(-t/TimeConstant)) [a]

When entering this function, you can select most of the required items by right-clicking in the Definition window in the Expression details view instead of typing them. The names of the existing expressions are under the Expressions menu. The exp and abs functions are under Functions > CEL. The variable t is under Variables.

Note: The

absfunction takes the modulus (or magnitude) of its argument. Even though the expression (1- exp (-t/TimeConstant)) can never be less than zero, the abs function is included to ensure that the numerical error in evaluating it near to zero will never make the expression evaluate to a negative number.

Next, you will visualize how the concentration of smoke issued from the vent varies with time.

Double-click

ExpFunctionin the Expressions tree view.Configure the following setting(s):

Tab

Setting

Value

Plot

t

(Selected)

t

> Start of Range

0 [s]

t

> End of Range

30 [s]

Click Plot Expression.

The button name then changes to Define Plot, as shown.

As can be seen, the smoke concentration rises to its asymptotic value reaching 90% of its final value at around 7 seconds.

Click the Boundary: Vent tab.

In the next step, you will apply the expression

ExpFunctionto the additional variablesmokeas it applies to theTransient AnalysisboundaryVent.Configure the following setting(s):

Tab

Setting

Value

Boundary Details

Additional Variables

> smoke

> Option

Value

Additional Variables

> smoke

> Add. Var. Value

ExpFunction [a]

Click .

When the Transient Analysis is run, the

initial values to the CFX-Solver will be taken from the results of the Steady State Analysis. The steady state and transient

analyses will be sequenced by setting up the configurations of these

analyses in a subsequent step. For the moment, you can leave all of

the initialization data set for the Transient Analysis to Automatic and the initial values will be

read automatically from the Steady State Analysis results. Therefore, there is no need to revisit the initialization

settings.

In the Outline tree view, ensure that

Simulation>Transient Analysis>Solveris expanded.Right-click

Simulation>Transient Analysis>Solver>Solver Controland select Edit.Set Convergence Control > Max. Coeff. Loops to

3.Leave the other settings at their default values.

Click to set the solver control parameters.

To enable results to be viewed at different time steps, it is necessary to create transient results files at specified times. The transient results files do not have to contain all solution data. In this step, you will create minimal transient results files.

In the Outline tree view, double-click

Simulation>Transient Analysis>Solver>Output Control.Click the Trn Results tab.

In the Transient Results tree view, click Add new item

, set Name to

, set Name to Transient Results 1, and click OK.Configure the following setting(s) of

Transient Results 1:Click .

In the Transient Results tree view, click Add new item

set Name to

set Name to Transient Results 2, and click OK.This creates a second transient results object. Each object can result in the production of many transient results files.

Configure the following setting(s) of

Transient Results 2:Setting

Value

Option

Selected Variables

Output Variables List

Pressure, Velocity, smoke

Output Frequency

> Option

Time Interval

Output Frequency

> Time Interval

4 [s] [a]

Click .

With two types of analysis for this simulation, configuration control is used to sequence these analyses.

To set up the Steady State Analysis so

that it will start at the beginning of the simulation:

In the Outline tree view, ensure that

Simulation Controlis expanded.Right-click

Simulation Control>Configurationsand select Insert > Configuration.Set Name to

Steady State.Click .

Configure the following setting(s):

Tab

Setting

Value

General Settings

Flow Analysis

Steady State Analysis

Activation Conditions

> Activation Condition 1

> Option

Start of Simulation

Click .

To set up the Transient Analysis so that

it will start upon the completion of the Steady State Analysis:

Right-click

Simulation Control>Configurationsand select Insert > Configuration.Set Name to

Transient.Click .

Configure the following setting(s):

Tab

Setting

Value

General Settings

Flow Analysis

Transient Analysis

Activation Conditions

> Activation Condition 1

> Option

End of Configuration

Activation Conditions

> Activation Condition 1

> Configuration Name

Steady State

Run Definition

Configuration Execution Control

Selected

Initial Values

Initial Values Specification

Selected

Initial Values Specification

> Initial Values

> Initial Values 1

> Option

Configuration Results

Initial Values Specification

> Initial Values

> Initial Values 1

> Configuration Name

Steady State

Click .

In the Outline tree view, right-click

Simulation Controland select Write Solver Input File.Configure the following setting(s):

Setting

Value

File of type

CFX-Solver Input Files (*.mdef)

File name

CircVent.mdef

Click .

This will create

CircVent.mdefas well as a directory namedCircVentthat containsSteadyState.cfgandTransient.cfg.Quit CFX-Pre, saving the case (

.cfx) file.

You can obtain a solution to the steady-state and transient configurations by using the following procedure.

Start CFX-Solver Manager.

From the menu bar, select File > Define Run.

Configure the following setting(s):

Setting

Value

Solver Input File

CircVent.mdef

Edit Configuration

Global Settings

Click Start Run.

CFX-Solver Manager will start with the solution of the steady-state configuration.

In the Workspace drop-down menu, select

SteadyState_001. The residual plots for six equations will appear: U - Mom, V - Mom, W - Mom, P - Mass, K-TurbKE, and E-Diss.K (the three momentum conservation equations, the mass conservation equation and equations for the turbulence kinetic energy and turbulence eddy dissipation). The Momentum and Mass tab contains four of the plots and the other two are under Turbulence Quantities. The residual for the smoke equation is also plotted but registers no values since it is not initialized.Upon the successful completion of the steady-state configuration, the solution of the transient configuration starts automatically. Notice that the text output generated by the CFX-Solver in the

Run Transient 001Workspace will be more than you have seen for steady-state problems. This is because each time step consists of several inner (coefficient) iterations. At the end of each time step, information about various quantities is printed to the text output area. The residual for the smoke equation is now plotted under the Additional Variables tab.Upon the successful completion of the combined steady-state and transient configurations, ensure that the check box beside Post-Process Results is cleared and click to close the message indicating the successful completion of the simulation.

In the CFX-Solver Manager, set Workspace to

Run CircVent 001.From the menu bar, select Tools > Post-Process Results.

On the Start CFD-Post dialog box, select Shut down CFX-Solver Manager and click .

In this part of the tutorial, you will:

Create an isosurface to illustrate the pattern of smoke concentration.

View results at different time steps.

Animate the results to view the dispersion of smoke from the vent over time.

Save the animation as an MPEG file.

Use volume rendering to show the visibility of smoke with its transparency.

An isosurface is a surface of constant value of a variable.

For instance, it could be a surface consisting of all points where

the velocity is 1 [m s^-1]. In this case, you are going

to create an isosurface of smoke concentration

(smoke is the Additional Variable that you specified

earlier).

In CFD-Post, right-click a blank area in the viewer and select Predefined Camera > Isometric View (Z up).

This ensures that the view is set to a position that is best suited to display the results.

From the menu bar, select Insert > Location > Isosurface, or under Location on the toolbar, click Isosurface.

Click to accept the default name.

Configure the following setting(s):

Tab

Setting

Value

Geometry

Variable

smoke

Value

0.005 [kg m^-3]

Click .

A bumpy surface is displayed, showing the smoke emanating from the vent.

The surface is rough because the mesh is coarse. For a smoother surface, you would re-run the problem with a smaller mesh length scale.

The surface will be a constant color because the default settings on the Color tab were used.

When Color Mode is set to either

ConstantorUse Plot Variablefor an isosurface, the isosurface is displayed in one color.

In Geometry, experiment by changing the Value setting so that you can see the shape of the plume more clearly.

Zoom in and rotate the geometry, as required.

When you have finished, set Value to

0.002 [kg m^-3].Right-click a blank spot in the viewer and select Predefined Camera > Isometric View (Z up).

When CFD-Post is loaded, the results that are immediately available are those at the final time step; in this case, at t = 30 s (this is nominally designated Final State). The Timestep Selector shows the Configuration, the step of the Simulation, the Step (outer loop) number, the Time (simulated time in seconds) of the configuration and the Type of results file that was saved at that time step for the configuration. You can see that Partial results files were saved (as requested in CFX-Pre) for all time steps in the transient configuration except for the last one.

Click Timestep Selector

.

.Load the results for a Time value of 2 s by double-clicking the appropriate row in the Timestep Selector.

After a short pause, the Loaded Timestep (located just below the title bar of the Timestep Selector) will be updated with the new time step number.

Load the time value of 4 s using the Timestep Selector.

The smoke has now spread out even more, and is being carried by the wind.

Double-click some more time values to see how the smoke plume grows with time.

Finish by loading a time value of 12 s.

You can produce titled image output from CFD-Post.

First, you will add text to the viewer so that the printed output has a title.

Select Insert > Text from the menu bar or click Create text

.

.Click to accept default name.

In the Text String box, enter the following text.

Isosurface showing smoke concentration of 0.002 kg/m^3 after

Note: Further text will be added at a later stage to complete this title.

Set Type to

Time Value.In the text line, note that

<aa>has been added to the end. This is where the time value will be placed.Click to create the title.

Click the Location tab to modify the position of the title.

The default settings for text objects center text at the top of the screen. To experiment with the position of the text, change the settings on the Location tab.

Under the Appearance tab, change Color Mode to

User Specifiedand select a new color.Click .

CFD-Post can save images in several different formats. In this section you will save an image in JPEG format.

Select File > Save Picture, or click Save Picture

.

.Set Format to

JPEG.Click Browse

next

to the File data box.

next

to the File data box.Browse to the directory where you want the file saved.

Enter a name for the JPEG file.

Click to set the file name and directory.

This sets the path and name for the file.

To save the file, click on the Save Picture dialog box.

To view the file or make a hard copy, use an application that supports JPEG files.

Turn off the visibility of the text object to hide it.

You can generate an MPEG file to show the transient flow of the plume of smoke. To generate a movie file, you use the Animation dialog box.

In the Timestep Selector, ensure that a time value of 0 s is loaded.

Click Animation

.

.The Animation dialog box appears.

Set Type to Timestep Animation.

Position the geometry so that you will be able to see the plume of smoke.

Click More Animation Options

to show more animation settings.

to show more animation settings.Ensure that the Repeat forever button

next to Repeat is not selected

(not depressed).

next to Repeat is not selected

(not depressed).Select Save Movie.

Set Format to

MPEG1.Click Browse

next

to Save Movie.

next

to Save Movie.Set File name to

CircVent.mpg.If required, set the path location to a different directory.

Click .

The movie file name (including path) has been set, but the animation has not yet been produced.

Click Play the animation

.

.The movie will be created as the animation proceeds.

This will be slow, because for each time step results will be loaded and objects will be created.

To view the movie file, you need to use a viewer that supports the MPEG format.

Note: To explore additional animation options, click the Options button. On the Advanced tab of Animation Options, there is a check box called Save Frames As Image Files. By selecting this check box, the JPEG or PPM files used to encode each frame of the movie will persist after movie creation; otherwise, they will be deleted.

The final time step has the greatest dispersion of smoke, so you will load only that time step, then view the smoke using the Volume Rendering feature.

Select File > Load Results.

In the Load Results File dialog box, select Load only the last results (the other default settings should remain unchanged) and ensure that File name is set to CircVent_001.mres. Click Open.

Note: A warning message appears. Click .

If necessary, right-click a blank spot in the viewer and select Predefined Camera > Isometric View (Z up).

In the Outline tree view, clear Isosurface 1 and Text 1.

Select Insert > Volume Rendering and set the Name to be

SmokeVolume.In the details view, set the following values:

Tab

Setting

Value

Geometry

Variable

smoke

Resolution

50

Transparency

.2

Color

Mode

Variable

Variable

smoke

Color Map

Greyscale

Click .

When you have finished, quit CFD-Post.