This tutorial includes:

- 33.1. Tutorial Features

- 33.2. Overview of the Problem to Solve

- 33.3. Preparing the Working Directory

- 33.4. Defining a Steady-state Case in CFX-Pre

- 33.5. Obtaining a Solution to the Steady-state Case

- 33.6. Defining a Transient Blade Row Case in CFX-Pre

- 33.7. Obtaining a Solution to the Transient Blade Row Case

- 33.8. Viewing the Time Transformation Results in CFD-Post

In this tutorial you will learn about:

Component | Feature | Details |

|---|---|---|

CFX-Pre | User Mode | Turbo Wizard |

General mode | ||

Analysis Type | Transient Blade Row | |

Fluid Type | Air Ideal Gas | |

Domain Type | Multiple Domains | |

Rotating Frame of Reference | ||

Turbulence Model | Shear Stress Transport | |

Heat Transfer | Total Energy | |

Boundary Conditions | Inlet (Subsonic) | |

Outlet (Subsonic) | ||

Wall (Counter Rotating) | ||

CFD-Post | Plots | Vector |

Contour | ||

Data Instancing | ||

Time Chart | ||

Animation |

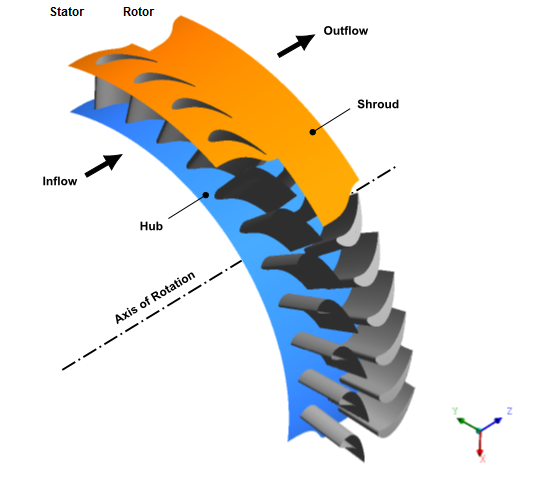

This tutorial sets up a transient blade row calculation using the Time Transformation model. It uses an axial turbine to illustrate the basic concepts of setting up, running, and monitoring a transient blade row problem in Ansys CFX. It also describes the postprocessing of transient blade row results using the tools provided in CFD-Post for this type of calculation.

The full geometry of the axial rotor-stator stage selected for modeling contains 36 stator blades and 42 rotor blades.

The geometry to be modeled consists of a single rotor blade passage and a single stator blade passage. Each rotor blade passage is an 8.571° section (360°/42 blades), while each stator blade passage is a 10° section (360°/36 blades). The pitch ratio at the interface between the rotor passage and the stator passage is 0.8571 (that is, 6/7).

For the Time Transformation method, you should always maintain an ensemble pitch ratio within a range of 0.75 to 1.4. Note that the range of permissible pitch ratios narrows significantly with slower rotation speed. A full machine analysis can be performed (modeling all rotor and stator blades), which always eliminates any pitch change, but will require significant computational time. For this rotor-stator geometry, a 1/6 machine section (7 rotor blades, 6 stator blades) would produce a pitch ratio of 1.0, but this would require a model about 7 times larger than in this tutorial example.

In this example, the rotor rotates about the Z axis at 3500 rev/min (positive rotation following the right hand rule) while the stator is stationary. Rotational periodicity boundaries are used to enable only a small section of the full geometry to be modeled.

The flow is modeled as being turbulent and compressible. Profile boundary conditions are used at the inlet and outlet. In this tutorial, the profiles are a function of the radial coordinate only. These profiles were obtained from previous simulations of the upstream and downstream stages.

The overall approach of this tutorial is to run a transient blade row simulation initialized with the results of a steady-state simulation. First, you will define a steady-state simulation using the Turbomachinery Wizard followed by General mode. While the steady-state simulation is running, you will modify a copy of it to define a transient blade row simulation that uses the Time Transformation model. After running the transient blade row simulation, you will create contour plots and an animation showing blade rotation.

If this is the first tutorial you are working with, it is important to review the following topics before beginning:

Create a working directory.

Ansys CFX uses a working directory as the default location for loading and saving files for a particular session or project.

Download the

time_blade_row.zipfile here .Unzip

time_blade_row.zipto your working directory.Ensure that the following tutorial input files are in your working directory:

TBRTurbineRotor.gtmTBRTurbineStator.gtmTBRInletProfile.csvTBROutletProfile.csv

Set the working directory and start CFX-Pre.

For details, see Setting the Working Directory and Starting Ansys CFX in Stand-alone Mode.

This tutorial uses the Turbomachinery wizard in CFX-Pre. This preprocessing mode is designed to simplify the setup of turbomachinery simulations.

In CFX-Pre, select > .

Select Turbomachinery and click .

Select > .

Under File name, type

TimeBladeRowIni.Click .

If you are notified that the file already exists, click .

In the Basic Settings panel, configure the following settings:

Setting

Value

Machine Type

Axial Turbine

Axes

> Rotation Axis

Z

Analysis Type

> Type

Steady State

Leave the other settings at their default values.

Click .

You will define two new components and import their respective meshes.

Right-click in the blank area and select Add Component from the shortcut menu.

Create a new component of type

StationarynamedS1and click .Configure the following setting(s):

Setting

Value

Mesh

> File

TBRTurbineStator.gtm [a]

Create a new component of type

Rotating, namedR1and click .Configure the following setting(s):

Setting

Value

Component Type

> Value

3500 [rev min^-1] [a]

Mesh

> File

TBRTurbineRotor.gtm

Click .

In this section you will set properties of the fluid domain and some solver parameters.

In the Physics Definition panel, configure the following:

Setting

Value

Fluid

Air Ideal Gas

Model Data

> Reference Pressure

0 [atm] [a]

Model Data

> Heat Transfer

Total Energy

Model Data

> Turbulence

Shear Stress Transport

Inflow/Outflow Boundary Templates

> P-Total Inlet P-Static Outlet

(Selected)

Inflow/Outflow Boundary Templates

> Inflow

> P-Total

169000 [Pa][b]

Inflow/Outflow Boundary Templates

> Inflow

> T-Total

306 [K][b]

Inflow/Outflow Boundary Templates

> Inflow

> Flow Direction

Normal to Boundary

Inflow/Outflow Boundary Templates

> Outflow

> P-Static

110000 [Pa][b]

Interface

> Default Type

Stage (Mixing-Plane)

Continue to click until you reach

Final Operations.Set Operation to

Enter General Modebecause you will continue to define the simulation through settings not available in the Turbomachinery wizard.Click .

Verify the following settings, which affect the accuracy of the simulation:

Edit

R1.Configure the following setting(s):

Tab

Setting

Value

Basic Settings

Domain Models

> Domain Motion

> Alternate Rotation Model

(Selected)

Fluid Models

Heat Transfer

> Incl. Viscous Work Term

(Selected)

Click .

The inlet and outlet boundary conditions are defined using profiles in your working directory. Boundary profile data must be initialized before they can be used for boundary conditions.

Select Tools > Initialize Profile Data.

The Initialize Profile Data dialog box appears.

Beside Profile Data File, click Browse

.

.The Select Profile Data File dialog box appears.

From your working directory, select

TBRInletProfile.csv.Click .

Click .

The profile data is read into memory.

Beside Profile Data File, click Browse

.

.The Select Profile Data File dialog box appears.

From your working directory, select

TBROutletProfile.csv.Click .

Click .

Note: After profile data has been initialized from a file, the profile data file should not be deleted or otherwise removed from its directory. By default, the full filepath to the profile data file is stored in CFX-Pre, and the profile data file is read directly by CFX-Solver each time the solver is started or restarted.

Edit

S1 Inlet.Configure the following setting(s):

Tab

Setting

Value

Basic Settings

Profile Boundary Conditions

> Use Profile Data

(Selected)

Profile Boundary Setup

> Profile Name

inlet

Click .

This causes the profile values of

Total PressureandTotal Temperatureto be applied at the nodes on the inlet boundary. It also causes entries to be made in the Boundary Details tab. In order to later reset the velocity values at the main inlet to match those that were originally read from the profile data file, revisit the Basic Settings tab for this boundary and click Generate Values.Configure the following setting(s):

Tab

Setting

Value

Boundary Details

Mass and Momentum

> Option

Total Pressure (stable)

Mass and Momentum

> Relative Pressure

inlet.Total Pressure(r)

Flow Direction

> Option

Cylindrical Components

Flow Direction

> Axial Component

1

Flow Direction

> Radial Component

0

Flow Direction

> Theta Component

0

Heat Transfer

> Total Temperature

inlet.Total Temperature(r)

Click .

Edit

R1 Outlet.Configure the following setting(s):

Tab

Setting

Value

Basic Settings

Frame Type

Rotating

Profile Boundary Conditions

> Use Profile Data

(Selected)

Profile Boundary Setup

> Profile Name

outlet

Click Generate Values.

Configure the following setting(s):

Tab

Setting

Value

Boundary Details

Mass And Momentum

> Option

Static Pressure

Mass and Momentum

> Relative Pressure

outlet.Pressure(r)

Click .

You can plot scalar profile values and vectors on inlet and outlet boundaries. In this section, you will edit a boundary so that you can visualize the pressure profile values at the inlet.

Edit

S1 InletConfigure the following setting(s):

Tab

Setting

Value

Plot Options

Boundary Contour

(Selected)

Profile Variable

Relative Pressure

Click Apply

CFX-Pre plots the total pressure radial profile at the inlet with the pressure values displayed in a legend.

Ensure that the Define Run dialog box is displayed in CFX-Solver Manager.

Click Start Run.

CFX-Solver runs and attempts to obtain a solution. At the end of the run, a dialog box is displayed stating that the simulation has ended.

Ensure that the Post-Process Results check box is cleared.

Click .

In the second part of the tutorial, you will modify the simulation from the first part of the tutorial to model the transient blade row.

This step involves opening the original simulation and saving it to a different location.

Ensure that the following tutorial input files are in your working directory:

TBRInletProfile.csvTBROutletProfile.csvTimeBladeRowIni.cfxTimeBladeRowIni_001.res

Set the working directory and start CFX-Pre if it is not already running.

For details, see Setting the Working Directory and Starting Ansys CFX in Stand-alone Mode.

If the original simulation is not already opened, then open

TimeBladeRowIni.cfx.Save the case as

TimeBladeRow.cfxin your working directory.

In this section, you will make use of the transient blade row feature.

Modify the analysis type as follows:

Edit

Analysis Type.Configure the following setting(s):

Setting

Value

Analysis Type

> Option

Transient Blade Row

Analysis Type

> Initial Time

> Option

Automatic with Value

Analysis Type

> Initial Time

> Time

0 [s]

Click .

Edit

R1 to S1.Configure the following setting(s):

Setting

Value

Interface Models

> Frame Change/Mixing Model

> Option

Transient Rotor Stator

Click .

You will set the simulation to be solved using the Time Transformation method.

Edit

Transient Blade Row Models.Set Transient Blade Row Model > Option to

Time Transformation.Under

Time Transformation, click Add new item , accept the default name, and click OK.

, accept the default name, and click OK.Configure the following setting(s):

Setting

Value

Transient Method

> Time Period

> Option

Passing Period

Transient Method

> Time Period

> Domain

S1

Transient Method

> Time Steps

> Option

Number of Timesteps per Period

Transient Method

> Time Steps

> Timesteps/Period

35

Transient Method

> Time Duration

> Option

Number of Periods per Run

Transient Method

> Time Duration

> Periods per Run

10

Note:The passing period is automatically calculated as: 2 * pi / (Passages in 360 * Signal Angular Velocity). The Passing Period setting cannot be edited.

The number of time steps per period should always be larger than 2 * Number of Fourier Coefficients + 1 to be used for postprocessing.

The time step size is also automatically calculated as: Passing Period / Number of Timesteps per Period. The Timestep setting cannot be edited.

Click .

For transient blade row calculations, a minimal set of variables

are selected to be computed using Fourier coefficients. It is convenient

to postprocess variables in the stationary frame when multiple frames

of reference are present. Here, you will add the Velocity

in Stn Frame and Mach Number in Stn Frame variables to the default list.

In addition, monitor points can be used to effectively compare the Time Transformation results against a reference case. They provide useful information on the quality of the reference phase and frequency produced in the simulation. They should be used to monitor convergence and, as the simulation converges, the user points should display a periodic pattern.

Note:

When comparing to a reference case, make sure monitor points are placed in the same relative locations with respect to the initial configuration in both cases.

It is important to check that the solver equations are being solved correctly. Monitoring pressure provides feedback on the momentum equations while monitoring temperature provides feedback on the energy equations.

Set up the output control and create monitor points as follows:

Click Output Control

.

.Click the Trn Results tab.

Configure the following setting(s):

Setting

Value

Transient Blade Row Results

> Extra Output Variables List

(Selected)

Transient Blade Row Results

> Extra Output Variables List

> Extra Output Var. List

Velocity in Stn Frame, Mach Number in Stn Frame[a]

Click the Monitor tab.

Configure the following setting(s):

Setting

Value

Monitor Objects

(Selected)

Monitor Objects

> Efficiency Output

(Cleared)

Create a monitor point named

rotor_P1.Under Monitor Objects > Monitor Points and Expressions > rotor_P1, configure the following settings:

Setting

Value

Option

Cylindrical Coordinates

Output Variables List

Pressure, Temperature, Total Pressure, Total Temperature, Velocity

Position Axial Comp.

0.211 [m]

Position Radial Comp.

0.2755 [m]

Position Theta Comp.

182 [degree]

Create an additional monitor point named

stator_P1.Under Monitor Objects > Monitor Points and Expressions > stator_P1, configure the following settings:

Setting

Value

Option

Cylindrical Coordinates

Output Variables List

Pressure, Temperature, Total Pressure, Total Temperature, Velocity

Position Axial Comp.

0.202 [m]

Position Radial Comp.

0.2755 [m]

Position Theta Comp.

178 [degree]

Note: Transient blade row cases use monitor points to monitor the periodic fluctuating variable values. For diagnostic purposes, you should have several monitor points. Here, two monitor points will be used for demonstration purposes.

Click .

Click Define Run

.

.Configure the following setting(s):

Setting

Value

File name

TimeBladeRow.def

Click .

Ignore the error message (the initial values will be specified in CFX-Solver Manager) and click to continue.

CFX-Solver Manager automatically starts and, on the Define Run dialog box, Solver Input File is set.

If using stand-alone mode, quit CFX-Pre, saving the simulation (

.cfx) file at your discretion.

At this point, CFX-Pre has been shut down, and the Define Run dialog box is displayed in CFX-Solver Manager. You will now obtain a solution to the CFD problem. To reduce the simulation time, the simulation will be initialized using a steady-state case.

Ensure that the Define Run dialog box is displayed. If an error message appears, ignore it and click to continue.

Solver Input File should be set to

TimeBladeRow.def.Under the Initial Values tab, select Initial Values Specification.

Under Initial Values Specification > Initial Values, select

Initial Values 1.Under Initial Values Specification > Initial Values > Initial Values 1 Settings > File Name, click Browse

.

.Select

TimeBladeRowIni_001.resfrom your working directory.Click Open.

Under Initial Values Specification > Use Mesh From, select

Solver Input File.Click .

CFX-Solver runs and attempts to obtain a solution. At the end of the run, a dialog box is displayed stating that the simulation has ended.

Note:Before the simulation begins, the "Transient Blade Row Post-processing Information" summary in the CFX-Solver Output file will display the time step range over which the solver will accumulate the Fourier coefficients.

Similarly, the "Time Transformation Stability" summary in the CFX-Solver Output file displays whether the rotor–stator pitch ratio is within the acceptable range.

After the CFX-Solver Manager has run for a short time, you can track the monitor points you created in CFX-Pre by clicking the Time Corrected User Points tab that appears at the top of the graphical interface of CFX-Solver Manager.

After the simulation has proceeded for some time, observe the periodic nature of the monitor point values.

When CFX-Solver is finished, select the check box next to Post-Process Results.

Click .

In a transient blade row run, flow field variables are compressed using the Fourier coefficient method. These variables are accumulated at the end of the simulation. This enables you to navigate through any time instance, within the common period, without having to load multiple transient results files. By default CFD-Post displays results corresponding to the end the simulation.

To get started, follow these steps:

Start CFD-Post and load

TimeBladeRow_001.res.When CFD-Post opens, if you see the Domain Selector dialog box, ensure that all the domains are selected, then click to load the results from these domains.

If you see a message regarding transient blade row postprocessing, click .

Create a turbo surface to be used for making plots:

Click the Turbo tab.

If you see the Turbo Initialization dialog box, click , otherwise click the button, which is visible initially by default, or after double-clicking the Initialization object in the Turbo tree view.

Select Insert > Location > Turbo Surface.

Change the name to

Span 50.Configure the following setting(s):

Tab

Setting

Value

Geometry

Definition

> Method

Constant Span

Definition

> Value

0.5

Click .

Turn off the visibility of

Span 50by clearing its check box in the Outline tree view.

Click Insert > Vector and accept the default name.

Configure the following setting(s):

Tab

Setting

Value

Geometry

Definition

> Locations

Span 50

Definition

> Variable

Velocity in Stn Frame

Click .

The vector plot shows

Velocity in Stn Framevalues corresponding to the end of a common period.The rotor domain is in the angular position corresponding to its location after 10 passing periods. Now you will align the rotor with the stator, as it was in the solver input file.

Click Timestep Selector

.

.Select the 1st time step.

Click to load the time step, and then click Close to exit the dialog box.

The rotor blades move to their starting positions.

Turn off the visibility of

Vector 1.Click Insert > Contour and accept the default name.

Configure the following setting(s):

Tab

Setting

Value

Geometry

Locations

Span 50

Variable

Pressure

Range

Local

# of Contours

21

Click .

The contour plot shows Pressure values

corresponding to the specified time step.

In this section, you will compute and plot the magnitude of the forces that the flow applies on the rotor blade. For a transient blade row case, CFD-Post automatically reconstructs variables for the flow solution time based on the last time step. Intermediate time steps for time instances in the common period are located in the Timestep Selector. In Setting up a Transient Blade Row Model, you set 35 time steps per stator blade passing period and there are six rotor blade passing periods in a common period. Therefore, the total number of intermediate time steps in the common period is 210. For this case, the solver has reconstructed results over two common periods (420 time steps). You will reduce the total number of time steps to 140 to speed up the generation of the time chart.

Reduce the number of time steps in the period:

Click Timestep Selector

.

.Configure the following setting(s):

Tab

Setting

Value

Timestep Selector

Timestep Sampling

Uniform

Number of Timesteps

70

Click .

The Timestep Selector now shows a total of 140 steps over two common periods (shown under the Phase column).

Compute the forces on the blade:

Select Insert > Expression.

In the Insert Expression dialog box, type

forces on rotor blade.Click .

Set Definition to

sqrt(force_x()@ R1 Blade ^2 + force_y()@ R1 Blade ^2 + force_z()@ R1 Blade ^2)Click to create the expression.

Create a transient chart showing force:

Select Insert > Chart and accept the default name.

Configure the following setting(s):

Tab

Setting

Value

General

XY - Transient or Sequence

(Selected)

Data Series

Series 1

> Data Source

> Expression

(Selected)

Data Series

Series 1

> Data Source

> Expression

forces on rotor blade

Click .

A chart showing force on a single rotor blade against time is created, added to the chart object, and displayed in the Chart Viewer.

In this section, you will create additional copies of the original passages that replicate mesh nodes at different locations with correct space and time interpolation values. After the data instancing process, CFD-Post will create additional mesh nodes proportional to the number of extra passages created, and populate them with solution variables correctly updated to their corresponding position in time and space.

From the Outline tree view, edit

R1.In the Data Instancing tab, set Number of Data Instances to 7.

Click .

From the Outline tree view, edit

S1.In the Data Instancing tab, set Number of Data Instances to 6.

Click .

Turn off the visibility of

Wireframe.

On the 3D Viewer tab, CFD-Post displays the group of blades corresponding to 1/6 of a full wheel (the minimum number of blades that makes a unity pitch ratio between stator and rotor passages).

The data-dependent transient forces on rotor blade on Chart 1 is still showing the result computed

on a single blade passage. After you expand the number of rotor blades

in the rotor passage to 7, the R1 Blade groups all 7 rotor blades together and the total force should be

updated. To update the chart, click the Refresh button at the top of the Chart Viewer.

The forces on rotor blade expression is

now being computed on all 7 blades in the extended number of passages

in the rotor.

In this section, you will create additional copies of the original

domain passage. For the current example, the original passage was

replicated by a number to assemble 1/6 of the wheel using the Data Instancing tool. Therefore, by applying the graphical

instancing on R1 and S1 you

will be making copies of the extended version of these passages.

From the Outline tree view, edit

R1.In the Instancing tab configure the following settings:

Tab

Setting

Value

Instancing

Number of Graphical Instances

6

Instance Definition

Custom

Passages per Component

7

Click .

From the Outline tree view, edit

S1.In the Instancing tab configure the following settings:

Tab

Setting

Value

Instancing

Number of Graphical Instances

6

Instance Definition

Custom

Passages per Component

6

Click .

The Graphics Instancing feature makes graphical copies of objects and places them at an angular position computed using the Number of Passages and Number of Passages per Component on the Instancing panel. To complete the full wheel, you replicated the 1/6 wheel sector, which was obtained using data instancing, six times. On the 3D Viewer tab, CFD-Post displays the pressure plot on

Span 50over the full wheel.

With the Timestep Selector set to time

step 0, you will make an animation showing the

relative motion starting from this time step and lasting for one stator

blade passing period.

Click the 3D Viewer tab.

Position the geometry for the animation by right-clicking on a blank area in the viewer and selecting Predefined Camera > View From -X.

Click Animation

.

.The Animation dialog box appears.

Set Type to Keyframe Animation.

Click New

to create

to create KeyframeNo1.Select

KeyframeNo1, then set # of Frames to70, then press Enter while in the # of Frames box.Tip: Be sure to press Enter and confirm that the new number appears in the list before continuing.

This will place 70 intermediate frames between the keyframes, for a total of 72 frames.

Use the Timestep Selector to load time step

70and then close the dialog box.In the Animation dialog box, click New to create

KeyframeNo2.Click More Animation Options

to expand the Animation dialog

box.

to expand the Animation dialog

box.Select Save Movie.

Specify a filename for the movie.

Set Format to

MPEG1.Click To Beginning

to rewind the active keyframe to

to rewind the active keyframe to KeyframeNo1.Note: The active keyframe is indicated by the value appearing in the F: field in the middle of the Animation dialog box. In this case it will be

1.Wait for CFD-Post to finish loading the objects for this frame before proceeding.

Click Save animation state

and save the animation to a file. This will enable

you to quickly restore the animation in case you want to make changes.

Animations are not restored by loading ordinary state files (those

with the

and save the animation to a file. This will enable

you to quickly restore the animation in case you want to make changes.

Animations are not restored by loading ordinary state files (those

with the .cstextension).Click Play the animation

.

.Note: It takes a while for the animation to be completed. To view the movie file, you will need to use a media player that supports the MPEG format.

From the animation and plots, you can see that the flow is continuous across the interface. This is because CFD-Post is capable of interpolating the flow field variables to the correct time and position using the computed Fourier coefficients.

When you have finished, close the Animation dialog box and then close CFD-Post, saving the animation state at your discretion.