The magnitude of the outlet velocity is specified and the direction is taken to be normal to the boundary at mesh resolution.

These are handled the same way as for an Inlet (Subsonic) boundary condition.

The Outlet Relative Static Pressure allows the pressure profile

at the outlet to vary based on upstream influences while constraining

the average pressure to a user-specified value , where:

(1–229) |

where is

the imposed pressure at each integration point and the integral is

evaluated over the entire outlet boundary surface. To enforce this

condition, the pressure at each boundary integration point is set

to:

(1–230) |

So, the integration point pressure in this case is set to the specified value plus the difference between the local nodal value and the average outlet boundary pressure. In this way the outlet pressure profile can vary, but the average value is constrained to the specified value.

In this case, the average pressure is only constrained in the region above or below the specified radius by shifting the calculated pressure profile by the difference between the specified average and the nodal average above or below the specified radius.

The circumferential averaging option divides the exit boundary condition into circumferential bands (oriented radially or axially depending on the geometry). The pressure within each band is constrained to the specified average pressure value the same way as is done for the overall averaging:

(1–231) |

where the specified value is applied within a band and the nodal average pressure is also calculated within a band.

The mass flux distribution across the outlet is determined by starting with the local mass flow rate distribution calculated by the flow solver at each integration point:

(1–232) |

From that distribution, you calculate the estimated total mass flow rate through the outlet boundary condition:

(1–233) |

where the summation is over all boundary integration points. A scaling factor is computed at the end of each coefficient loop that is used to scale the local integration point mass flows such that they add up to the specified mass flow rate:

(1–234) |

Iteratively, during the computation, can be greater than

or less than unity. The final integration point mass flows are reset

by multiplying the integration point mass flows by the scaling factor:

(1–235) |

In this way, the mass flux profile is an implicit result of the solution and at the same time gives exactly the specified mass flow rate.

This condition differs from the last one in that pressure is shifted in the continuity equation to get the specified mass flow rate. Generally speaking, the mass flow rate at each boundary integration point is dependent upon both velocity and pressure:

(1–236) |

where the integration point velocity depends upon nodal velocity and integration point pressures through the Rhie-Chow coupling. For this boundary condition, the integration point pressures are given by an expression of the form:

(1–237) |

where is an optional

specified pressure profile,

is the boundary

node pressure,

is the outlet boundary nodal average pressure,

is the Pressure Profile Blend factor that sets how much the specified

profile influences the boundary condition, and

is the level shift factor automatically computed

by the CFX-Solver each coefficient loop to enforce the specified mass

flow rate, such that:

(1–238) |

where the sum, in this case, is over all the outlet boundary condition integration points.

A further extension of the shift pressure feature for outlet mass flow rate conditions (or outlet boundaries using an Average Static Pressure specification) enforces the specified profile as an average pressure profile (or average pressure) in circumferential bands (radial or axial), held at a particular value.

Starting with the original formula for the integration point pressure in Equation 1–237: instead of imposing a particular profile distribution, an average pressure profile within bands is introduced:

(1–239) |

where: is the average pressure desired in band

, and

is the current average nodal value

in band

.

corresponds

to the Pressure Profile Blend factor. When

the specified profile spatially varies, the flow solver will compute

the average of that profile within each band and then use those

values for

.

The Exit Corrected Mass Flow Rate (ECMF) boundary condition allows you to specify an equivalent mass flow rate corrected to a user specified reference temperature and pressure. If the reference conditions are not provided, reference conditions will default to 1 [atm] and 15 [°C], corresponding to Standard Atmosphere Sea Level Static conditions.

Performance of compressible turbomachinery is generally dependent on ten variables; blade tip diameter, rotational speed, mass flow rate, inlet total temperature and pressure, exit total temperature and pressure, gas constant, specific heat ratio, and viscosity. These ten variables may be reduced to six similarity criteria: pressure ratio, temperature ratio, non-dimensional mass flow, non-dimensional speed, Reynolds number, and the ratio of specific heats.

The non-dimensional mass flow parameter () is taken as the ratio of

the actual mass flow rate to that which would pass through an orifice

of diameter

with a velocity equal to the stagnation speed of sound.

(1–240) |

where and

are the stagnation (total)

density and speed of sound at the outlet, respectively. The ECMF is

obtained by multiplying the non-dimensional mass flow by a constant

value equal to the mass that would pass through an orifice of the

same diameter,

, at a speed equal to the speed of sound at reference conditions.

(1–241) |

For ideal gases, we can substitute and

with:

at the local and reference conditions, where is the ratio of specific

heats and

is the specific gas constant.

This reduces Equation 1–241to:

(1–242) |

where and

are the stationary

frame total pressure and total temperature at the outlet.

To obtain a mass flow at the boundary, Equation 1–242is rearranged to obtain the actual mass flow rate based on the current outlet conditions and the specified corrected mass flow, written as:

(1–243) |

where, and

are mass averaged values of total pressure and temperature

in the stationary frame at the outlet.

Note that the current implementation is based on the ideal gas

reduction above. While the boundary condition will still provide the

stability benefits for non-ideal gas simulations, the specified corrected

mass flow may not correspond exactly to Equation 1–241due to differences in how and

are computed from the equation of state.

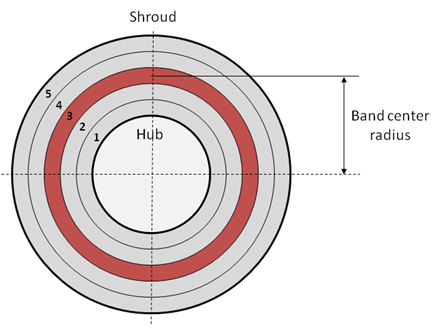

The radial equilibrium option divides the boundary condition into radially oriented circumferential bands. The pressure within each band is constrained by the radial equilibrium condition:

(1–244) |

This equation is used to calculate the pressure gradient in each band,

, based on the band

averaged tangential velocity,

, and density,

, as well as the band center

radius,

. The band edge pressures,

, are obtained by

integrating this equation starting from the specified pressure at

the radial reference position. This pressure is used to constrain

the solution pressure with the following equation:

(1–245) |

where:

is the area average nodal pressure, within a band

is linearly interpolated between the band edge values to the local face radius, r

and

is the evaluated pressure at the band mid-radius.

As for all average static-pressure options, the pressure profile

blend factor, F, can be applied to this boundary

condition. If the factor F=,1 then the pressure

at each face is fully constrained to the pressure obtained from the

radial equilibrium condition, , so that a circumferential profile

is not allowed within the band. If the factor F=0, then a circumferential profile is allowed to develop with the

average of that profile equal to the radial equilibrium pressure.