VM233

VM233

Static Force Computation of a 3D Solenoid Actuator

Overview

| Reference: |

M. Gyimesi, D. F. Ostergaard, "Analysis of Benchmark Problem TEAM20 with Various Formulations", Proceedings of TEAM Workshop, COMPUMAG, Rio, 1997. M. Gyimesi, D. F. Ostergaard, "Mixed Shape Non-Conforming Edge Elements", IEEE Transactions on Magnetics, Vol. 35 No. 3, 1999, pp. 1407-1409. M. Gyimesi, D. F. Ostergaard, "Non-Conforming Hexahedral Edge Elements for Magnetic Analysis", IEEE Transactions on Magnetics, Vol 34 No. 5, 1998, pp. 2481-2484. |

| Analysis Type(s): | Static (ANTYPE = 0) |

| Element Type(s): | Tetrahedral Coupled-Field Solid Elements (SOLID98) |

| Input Listing: |

VM233 requires a supplemental .cdb input file which is too long to include full input listings. This file must be present in your working directory for the test case to run properly. Additionally, the geometry and mesh should be regenerated. Download link: MAPDL Test Case Files for 2024 R2 vm233.cdb vm233.iges |

Test Case

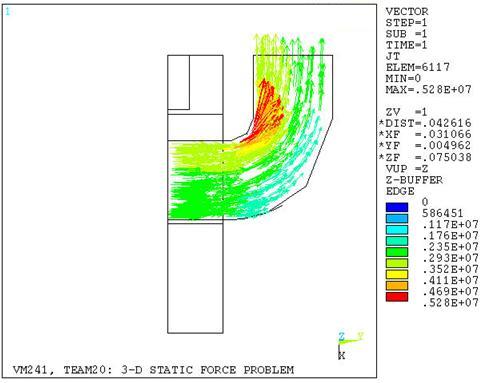

For the given solenoid actuator with an applied total coil current of 5000 A-turns, find the magnetic flux density (BZ) of the Pole, the magnetic flux density (BZ) of the Arm, and the Virtual Work Force in the Z-direction (See Problem Description for location of parts).

| Material Properties | Geometric Properties | Loading | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

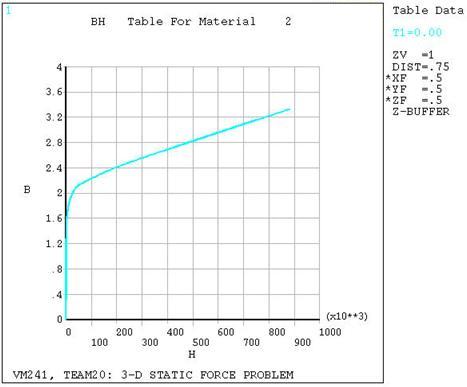

|

|

|

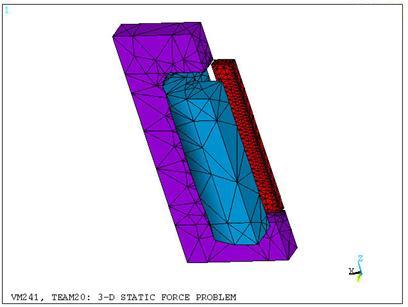

Analysis Assumptions and Modeling Notes

This analysis is based on the TEAM workshop problem 20. It utilizes the Difference Scalar Potential (DSP) element formulation with tetrahedral shaped SOLID98 elements. DSP formulation was used because it has much better accuracy than the Magnetic Vector Potential (MVP) method. Additionally, it is more efficient than the EDGE formulation method. To simplify meshing, the SMRTSIZE meshing option was used to automatically determine line divisions and spacing ratios while taking into account the line proximity effects. Mesh density can be adjusted using the SmartSize parameter, for this case, a SmartSizing level of 10 was applied. The analysis is performed using a quarter symmetry model of the solenoid actuator. The magnetic coil was created using the RACE command.