VM18

VM18

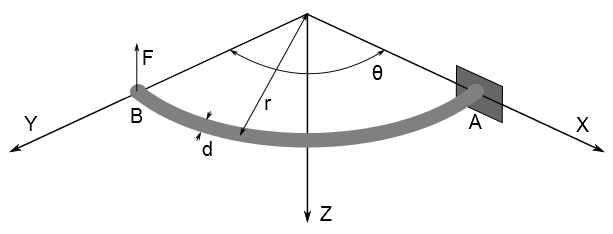

Out-of-Plane Bending of a Curved Bar

Test Case

A portion of a horizontal circular ring, built-in at A, is loaded

by a vertical (Z) load F applied at the end B. The ring has a solid

circular cross-section of diameter d. Determine the deflection δ

at end B, the maximum bending stress σBend, and the maximum torsional shear stress τ.

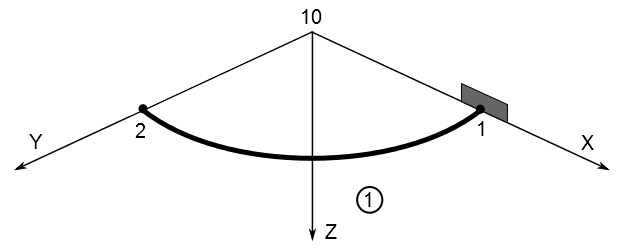

Analysis Assumptions and Modeling Notes

Node 10 is arbitrarily located on the

radius of curvature side of the element to define the plane of the

elbow when PIPE18 elements are used. The

wall thickness is set to half the diameter for a solid bar. Since

the section has no hole in the middle, ovalization cannot occur and PIPE289 elements can be used to determine the deflection

and stresses.

Results Comparison

Corresponds to maximum SAXL at

0° angle location in element solution output.

Corresponds to SXH at 0°

angle location in element solution output.