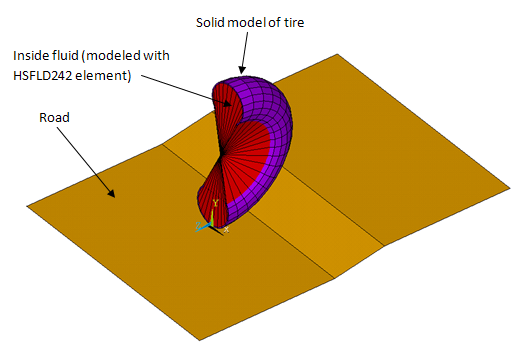

A 3D tire model is inflated and pressed against the road surface and then rolled over a bump on the road. The tire is modeled with hyperelastic material and reinforcing elements. The air inside is modeled with a hydrostatic fluid element, and the pressure, volume and density is monitored as loads are applied to the tire.

The tire is inflated to 36 psi and a mass of 1 ton is added at the axle to simulate the portion of the vehicle's mass resting on that axle.

The analysis occurs over five load steps, as follows:

Apply a gravity load and set the reference temperature for the air.

Inflate the tire.

Move the tire down to seat it on the road surface.

Remove displacement and pressure boundary conditions.

Apply an acceleration boundary condition to roll the tire over a bump.

Load steps 1 through 4 are performed statically, while load step 5 is performed as a transient analysis to study the loading effect on vertical acceleration.