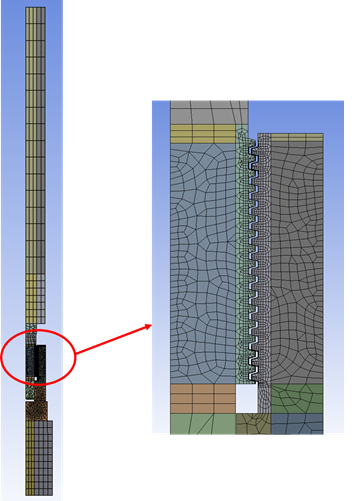

The model uses the PLANE182 2D four-node structural solid element with axisymmetric behavior (KEYOPT(3) = 1):

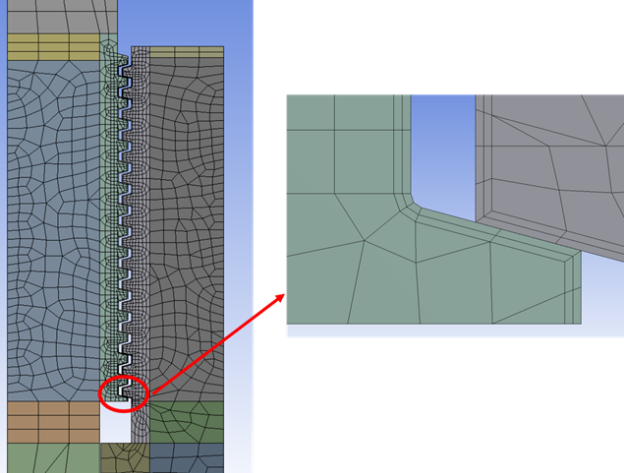

The mapped mesh for threads at critical locations are given an adequate mesh density:

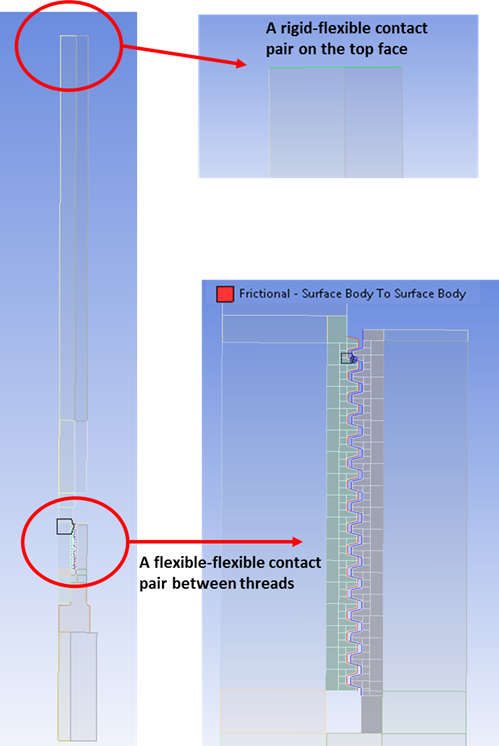

The 2D axisymmetric model of the threaded connection has two contact pairs:

The flexible-to-flexible contact pair uses a low value of friction (µ= 0.05). A very small amount of initial penetration (included in the contact analysis) exists between threads. You can change some properties of this contact pair (such as including/excluding the initial penetration or modifying the pinball region) during the 2D to 3D mapping process. Some experimentation may be necessary to determine the contact parameters to resolve convergence issues (if any) occuring during solution mapping (MAP2DTO3D,SOLVE).

The rigid-to-flexible contact pair plays no role in the 2D axisymmetric analysis. It is required for the 3D model, however, when applying the bending load on the extruded 3D model (via a pilot node created for this contact pair).

When the 2D axisymmetric mesh is extruded to the 3D mesh (EEXTRUDE), the program creates both contact pairs for the 3D model.

For more information about the 2D to 3D mapping process, see Analysis and Solution Controls.