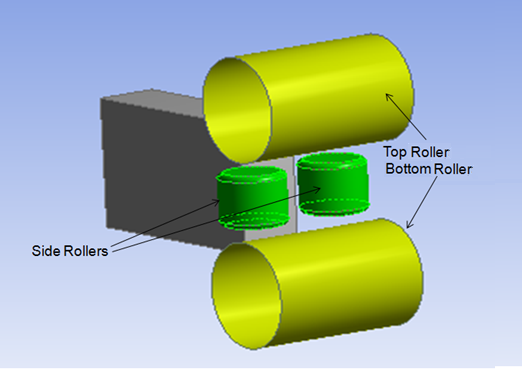

A rectangular block is passed through set of rollers to obtain an I-shaped beam, as shown in the following figure:

Two types of rollers are used:

Top and bottom rollers

Horizontal cylindrical rollers pull the block from the top and bottom to increase the width and reduce the depth of the block. The rollers control the width of the flange parts of the I-shape; they are modeled using rigid target elements.

Side rollers

Vertical cylindrical rollers with small fillets at either end. The fillets are necessary to ensure smooth material flow. The side rollers pull the block from the sides to create the I-shaped cross section. They control the width of the web part of the I-shape. As with the top and bottom rollers, the side rollers are modeled using rigid target elements.

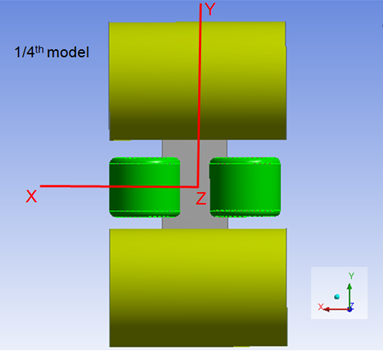

The following figure shows that the problem is symmetrical about two planes (XZ and YZ):

To reduce modeling and computational time, therefore, only one quarter of the model is analyzed. After the analysis has completed, however, the results are viewable in the full model by performing symmetry expansion about two planes of symmetry.

The simulation is performed statically in two load steps. In the first load step, the block is moved towards fully constrained rigid rollers in order to build up the rolling process. In the second load step, hot-rolling is performed by rotating the rollers about their axes of rotation, and the block is free to move in the horizontal direction (Z).

As the rollers rotate, the block passes through them due to the high level of friction between the rollers and the block. Eventually, the full block passes through the rollers to achieve the I-shaped cross section. In such large-deformation problems, however, mesh distortion is common, leading to convergence difficulties or eventual analysis termination.

The analysis diverges in the first load step due to excessive distortion in a few elements. A rezoning operation repairs the distorted mesh and allows the analysis to continue.