In turbomachinery engineering, the hot-to-cold method is commonly used to design rotor blades. The rotor blade geometry that would represent the as-manufactured shape is referred as cold geometry, whereas the shape of the rotor blade in the running condition is referred as hot geometry.

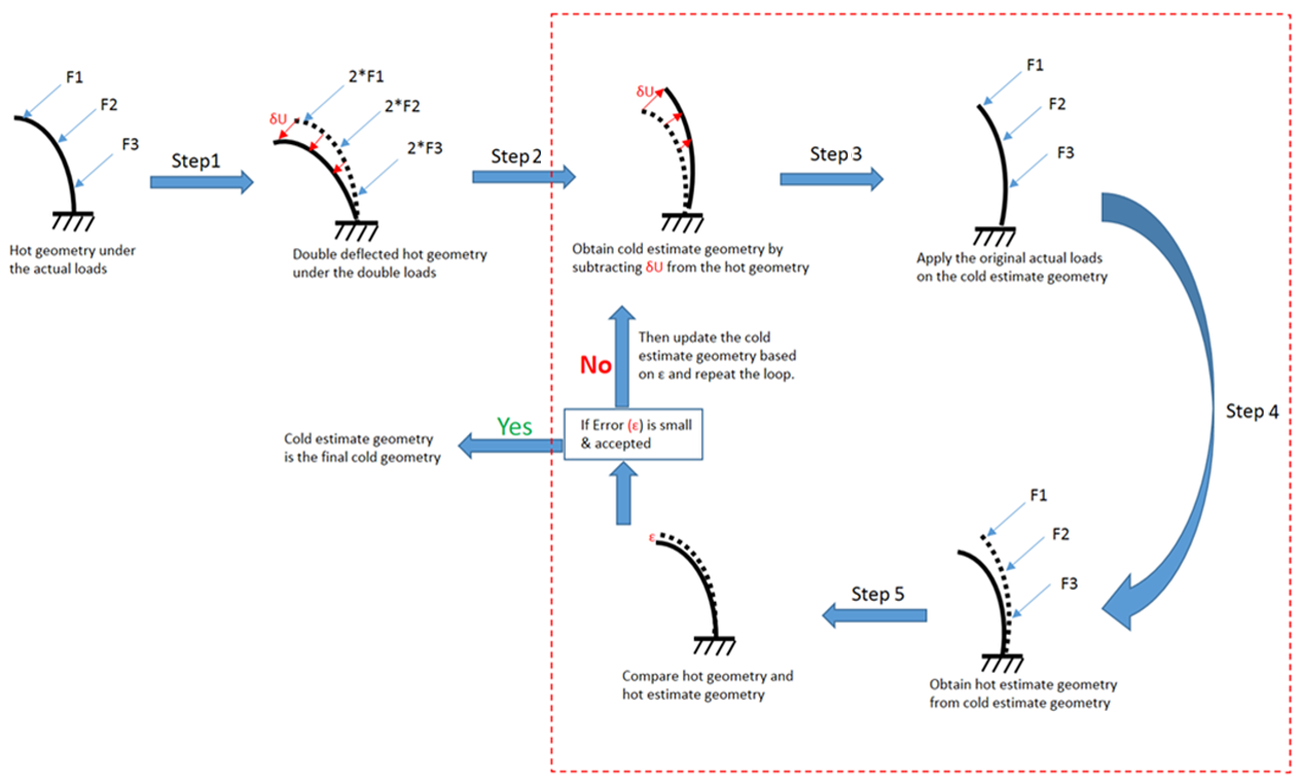

The designer begins with the hot geometry of the blade and determines the final shape of the hot geometry via design optimization. When the desired hot geometry has been determined, the designer uses an iterative approach to obtain the cold geometry of the blade to manufacture. Following is a typical work flow of the iterative approach for a simple beam model:

The first step of the iterative approach is to solve the hot geometry again with the aerodynamic, centripetal, and other loads to obtain the double-deflected hot geometry. The displacement results of this analysis are applied to the original hot geometry in the negative direction to obtain the first cold-estimate geometry. The cold-estimate geometry is again subjected to the same loads to obtain the hot-estimate geometry.

The hot-estimate geometry is then compared to the original hot geometry. If the difference is acceptably small, the cold estimate geometry is considered to be the final cold geometry; otherwise, the cold-estimate geometry is updated based on the difference and the process is continued until an acceptable comparison is obtained.

Achieving the desired accuracy via the iterative approach is resource- and time-intensive, as each iteration is a nonlinear solution involving perhaps many substeps.

By using inverse solving, however, it is possible to obtain the cold geometry from the hot geometry in a single solution.

Generally, inverse solving is useful in following cases:

When the input geometry is deformed and the material properties and loads that caused the deformation geometry are known, but the undeformed reference geometry and stresses/strains associated with the deformed input geometry are unknown. The problem presented here demonstrates this case.

When the input geometry is deformed and the material properties and loads that caused the deformed geometry are known, but it is necessary to solve the model with additional loadings. This case is common in biomechanical simulations, where the goal is to determine the stresses and strains on the input geometry and, more importantly, the deformed shape with further loading and the stresses/strains produced. In such cases, a nonlinear static analysis using inverse solving is required to recover the undeformed reference geometry, followed by a standard forward-solving analysis to apply further loading.

For more information, see Nonlinear Static Analysis with Inverse Solving in the Structural Analysis Guide.