As with an isotropic yield criteria that includes work hardening,

we can use a uniaxial tension test to obtain the relationship between and

. In practice the master

curve can be calculated from any normal or shear

stress-strain test. In this example we choose to use a 0° uniaxial

tension test.

In this case the quadratic yield function Equation 3–29 reduces to,

(6–3) |

and using the definition of effective stress Equation 3–38, the relationship between effective stress and σ22 is

(6–4) |

In general for uniaxial loading the following relationship results:

(6–5) |

and, from Equation 3–33 the associated incremental plastic strain components are

(6–6) |

On substitution of Equation 6–6 into the expression for incremental effective plastic strain Equation 3–40 we find that for uniaxial loadings

(6–7) |

For pure shear loading the same arguments result in the following relationship for effective stress and effective plastic strain increment,

(6–8) |

(6–9) |

where rr = 44, 55, or 66 depending on shear stress components.

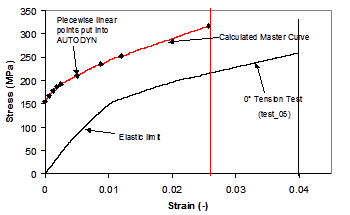

Derivation of the plasticity parameters is best illustrated

by an example. In the following discussion results from tension tests

on a 0°/90° woven Kevlar-epoxy composite material are presented

[2]. In this case the stress-strain

behavior in the 0°, or 22 direction, is considered to define

the master curve. The plasticity parameter a22

in this case is

a free parameter and we are at liberty to set its value simply to

1.0. Equation 6–5 and Equation 6–6 are now used to transform the

measured values of σ22 and ε22 into effective stresses and effective incremental

plastic strains thus determining the required master curve, as shown

in Figure 6.1: Derivation of Master

Relationship from Uniaxial Tension

Test.

Kevlar-epoxy is a 0°/90° woven material and is assumed

to be transversely isotropic, therefore a22

= a33

= 1.0. The in-plane plastic Poisson’s ratio was

calculated as 0.26 from 0° tension tests where strain was measured

in both in-plane directions. It was calculated from the average gradient

of measured strains immediately after yielding (see Figure 6.2: Longitudinal Versus Transverse Strain Measured in 0° Tension

Tests. Red Line Indicates Region used to Calculate Value for In-Plane

Poissons Ratio. (Picture Courtesy of EMI [2])).

Figure 6.2: Longitudinal Versus Transverse Strain Measured in 0° Tension Tests. Red Line Indicates Region used to Calculate Value for In-Plane Poissons Ratio. (Picture Courtesy of EMI [2])

![Longitudinal Versus Transverse Strain Measured in 0° Tension Tests. Red Line Indicates Region used to Calculate Value for In-Plane Poissons Ratio. (Picture Courtesy of EMI [])](graphics/adyn_comp_mat_props2.png)

Therefore from Equation 3–35, a23 can now be calculated as follows:

(6–10) |

The out-of-plane PPR was estimated as 0.698

from the 0° tension tests where strain was additionally measured

in the through thickness direction.

Therefore from Equation 3–35, a12 , and hence a13 , can now be calculated as follows:

(6–11) |

(6–12) |

The a44 plasticity coefficient was calibrated through simulation of the uniaxial tension test with loading at +/- 45° to the fibers. Using the plasticity coefficients derived so far in this section the quadratic yield function is sufficiently described to allow a44 to be modified until the 45° tension test results were reproduced.

Best agreement with experiment is achieved with a44 = 4.0 (see Figure 6.3: Results from Simulations of 45° Tension Tests. (Experimental Result Courtesy of EMI [2])).

Figure 6.3: Results from Simulations of 45° Tension Tests. (Experimental Result Courtesy of EMI [2])

![Results from Simulations of 45° Tension Tests. (Experimental Result Courtesy of EMI [])](graphics/adyn_comp_mat_props3.png)

In the absence of further experimental data it was assumed the out-of-plane shear plasticity coefficients are equal to the in-plane properties. Therefore,

(6–13) |