The failure initiation criteria can be considered as surfaces that define regions of valid stress. If a state of stress is found to lay outside of this surface a backward-Euler algorithm is used to return the stress to the failure surface. The resulting inelastic increment in strain is then accumulated as crack strain εcr . The maximum stress that can be sustained in an element is then reduced as a function of crack strain.

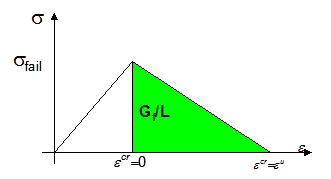

In this approach the area under the softening portion of the stress/strain curve is related to the fracture energy Gf , which is a material property. This is simply illustrated in Figure 4.1: Schematic Illustration of Crack Softening Algorithm.

A mathematical description of Figure 4.1: Schematic Illustration of Crack Softening Algorithm can be written as,

(4–7) |

where L is a characteristic cell dimension in the direction of failure and is included to improve the objectivity of the solution.

Failure is initiated when the stress reaches the value required for failure σfail . At this point the crack strain εcr is zero. A linear softening slope is assumed and therefore the ultimate crack strain εU , the strain at which tensile stresses can no longer be sustained, is calculated as:

(4–8) |

The gradient of the linear softening slope is given by:

(4–9) |

After failure initiation a linear damage law is used to reduce the maximum material stress in a cell as a function of crack strain.

(4–10) |

At initiation εcr = 0, therefore Dam = 0 . When the cell has no strength, Dam = 1. At any point between these times the maximum tensile material stress that can be supported in the cell is:

(4–11) |

Rather than define an effective crack strain analogous to effective plastic strain, damage has been implemented as a full tensor

(4–12) |

Each component of Equation 4–12 has an independent damage variable associated with it resulting in orthotropic damage. If we examine the 11-plane softening surface, damage is included for each stress component as follows,

(4–13) |

As with the hardening behavior of Orthotropic Yield Strength and Hardening Model an associative flow rule is assumed when returning the stresses to the softening surfaces,

(4–14) |

Considering the flow rule Equation 4–14 the incremental crack strain components are calculated as follows for the 11-plane softening surface Equation 4–13,

(4–15) |

The possibility that an increase in damage in a particular direction may reduce the maximum strength in other directions can be incorporated via the damage coupling coefficient, C. The value of C can vary between 0 and 1. For example, for the failure surface considered above, the damage increments are updated as,

Similar equations are trivially derived for the other softening surfaces.

If an element is fully damaged in two or more material directions, bulk failure is assumed:

| Damage Direction | Post Failure Response |

|

D11 = 1.0 | Zero tensile stress in all directions |

|

D22 = 1.0 | Zero tensile stress in all directions |

|

D11 = 1.0 | Zero tensile stress in all directions |