Voxel Size

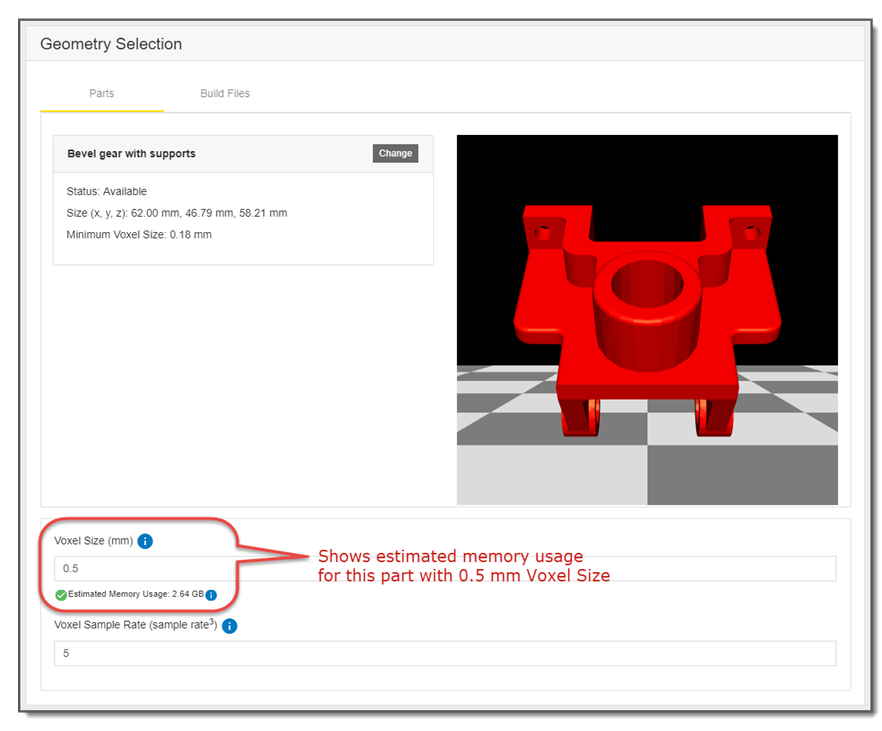

Upon adding a part to the simulation form, you will see a preview of that part as well as a summary of the part’s overall dimensions in millimeters in x, y, and z coordinates, a minimum Voxel Size recommendation, and an estimate for memory usage.

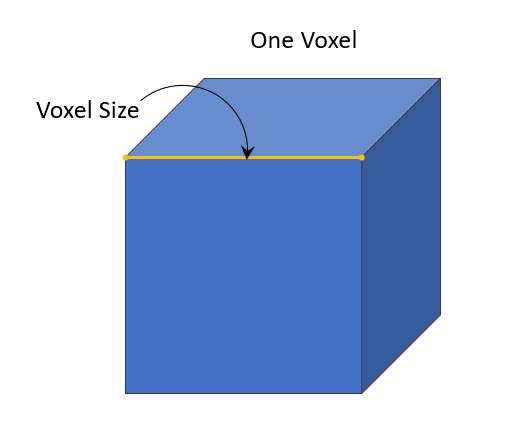

You will need to specify a Voxel Size and a Voxel Sample Rate to be used for your simulation. A voxel is a hexahedral (cubic) element used in the finite element method. In the following figure of a voxel, Voxel Size is the length of the yellow line.

When combined, voxels define the domain of the geometry. Minimum Voxel Size is the estimated Voxel Size that can safely run without the simulation risking failure due to insufficient memory. This is calculated automatically when the part is imported. Voxel size defaults to 0.5 mm.

Voxel Sample Rate

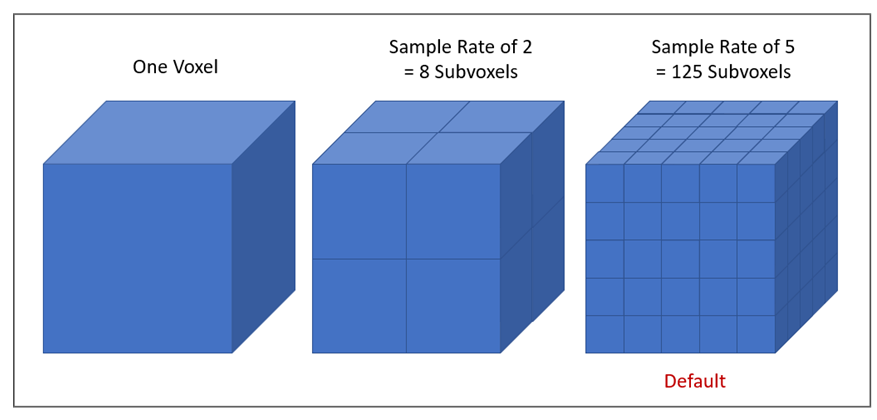

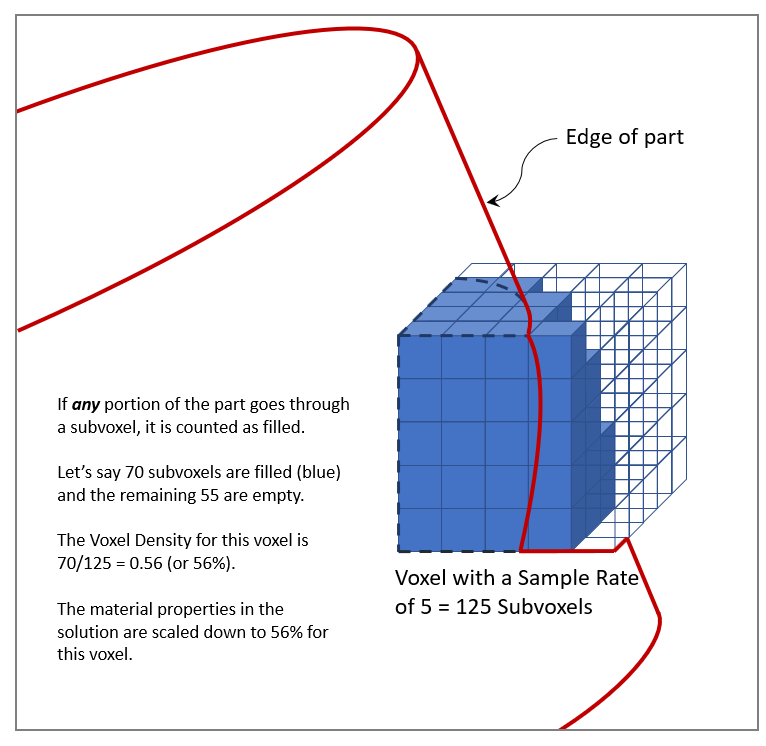

The voxelization function divides the domain into voxels for simulation in the Mechanics Solver. The technique employs subvoxels within each voxel to better represent geometry, in particular at edges and curves. A user input parameter, Voxel Sample Rate, allows control over the number of subvoxels to be used, ultimately controlling the trade-off between voxelization time and accuracy of geometry representation. A higher number than the default of 5 may sometimes be necessary to adequately capture fine supports and part features.

The following figure illustrates how subvoxels are used in defining the edges of geometries.

How Do I Determine Voxel Size?

Currently, the calculated Minimum Voxel Size assumes a Minimum Overhang Angle of 45 degrees and a Minimum Support Height of zero. (See Define Support Options for further details about supports.) A smaller angle could result in fewer support voxels and a Minimum Support Height > 0 will include more support voxels. In both cases, memory requirements will change, and a larger Voxel Size may be required for a successful simulation.

Generally, there should be at least four voxels through the thickness of the finest feature of interest. This is accomplished by setting the Voxel Size to one-fourth the minimum feature dimension. It should be noted however, that for a geometry with highly disproportionate overall dimensions compared to its finest features, some accuracy may be sacrificed in the fine features to obtain a shorter run time by applying the above rule to a thicker area of the part.

How Does Voxel Size Affect Run Time?

Decreasing Voxel Size by any factor can exponentially increase the solution run time by that factor raised to the power of 4 (assuming a uniform part, like a cube).

As an example, if the starting Voxel Size takes 5 minutes of run time, and then the Voxel Size is reduced by a factor of two, the run time could be expected to increase to approximately 5*(2) 4 = 80 minutes.

Currently, Voxel Size is limited to between 0.02 mm and 2 mm. However, due to memory requirements of smaller Voxel Size simulations, this range of Voxel Size is not guaranteed to finish the simulation.