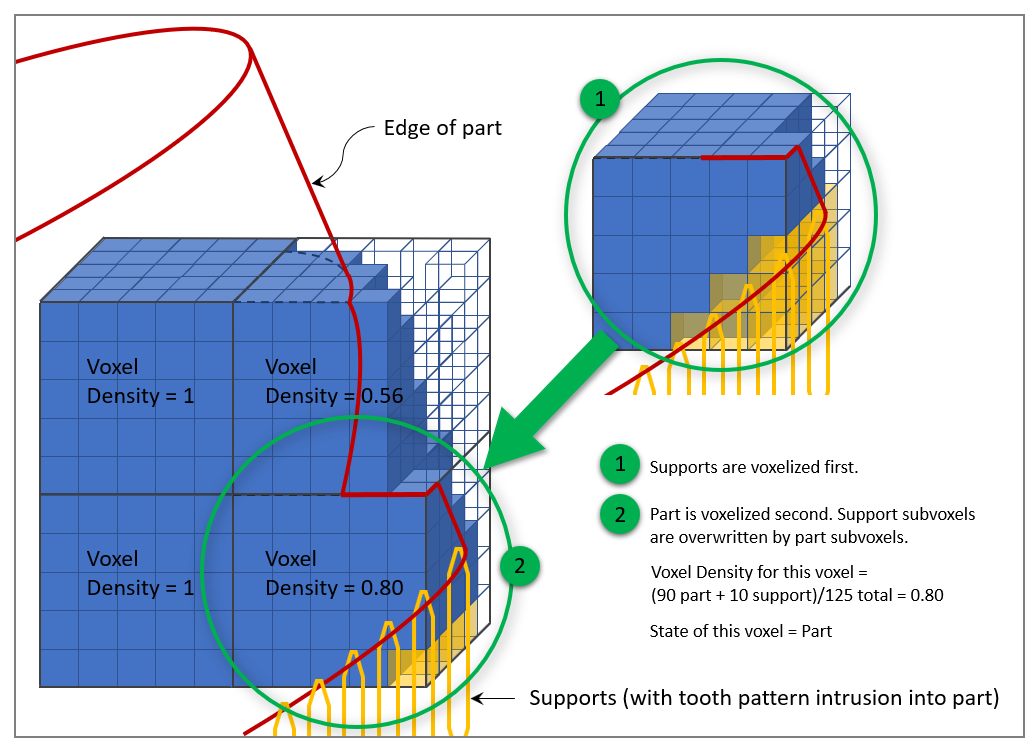

It is common practice when additively manufacturing parts for supports to intrude, or penetrate, into part geometry. This ensures a good connection between the part and the support. The following steps describe how the Additive application handles the interface between part and support when an stl support file includes intrusion of support walls into part geometry:

The support is voxelized at subvoxel resolution, marking the state of support subvoxels as support material.

The part is voxelized at subvoxel resolution, marking the state of part subvoxels as part material, and overwriting any support subvoxels that happen to be in the way (that is, coincident).

For each voxel, the resulting part subvoxels and support subvoxels are tallied up.

The voxel's density = (# non-empty subvoxels) / (# total subvoxels).

The voxel's state is considered support material if the voxel contains only support subvoxels. Otherwise, if there is at least one subvoxel marked as part, the voxel's state is considered part material.

So where there is overlap, there is no double-counting of density; the part material takes precedence over the support material. This is relevant because, as discussed later, the support material's strength is multiplied by a knockdown factor called Support Yield Strength Ratio.