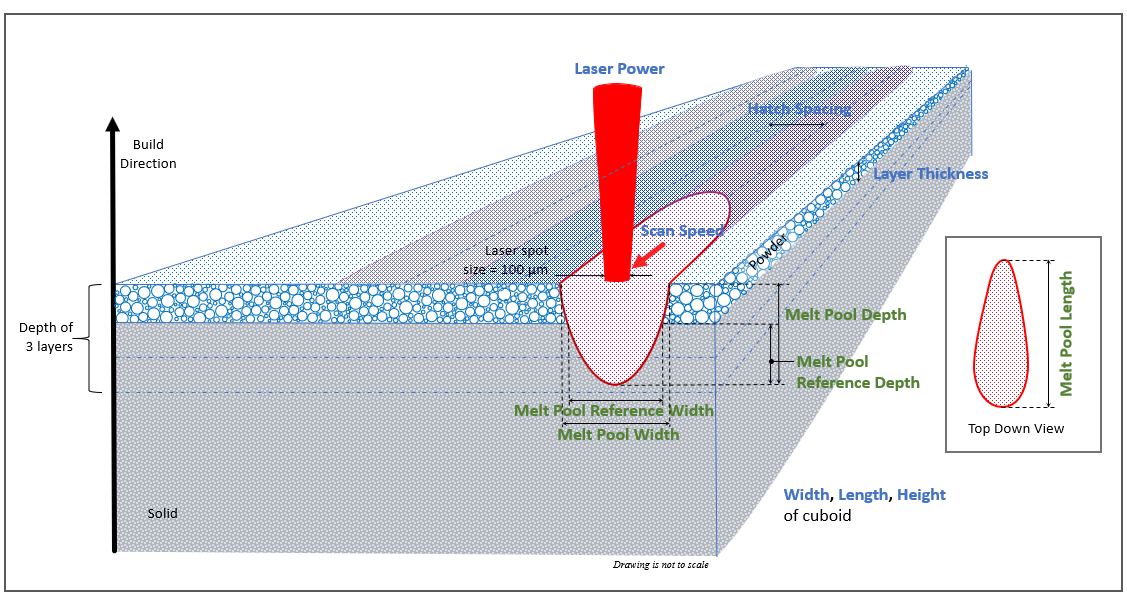

Following Single Bead Parametric simulations, typically you will want to expand your exploration to include Porosity Parametric simulations. Porosity simulations are used to obtain information about the level of porosity in additively manufactured material. They are set up to follow the industry practice of building full 3D cubes (or cuboids) on PBF machines in which many layers are printed using your chosen material and scan pattern.

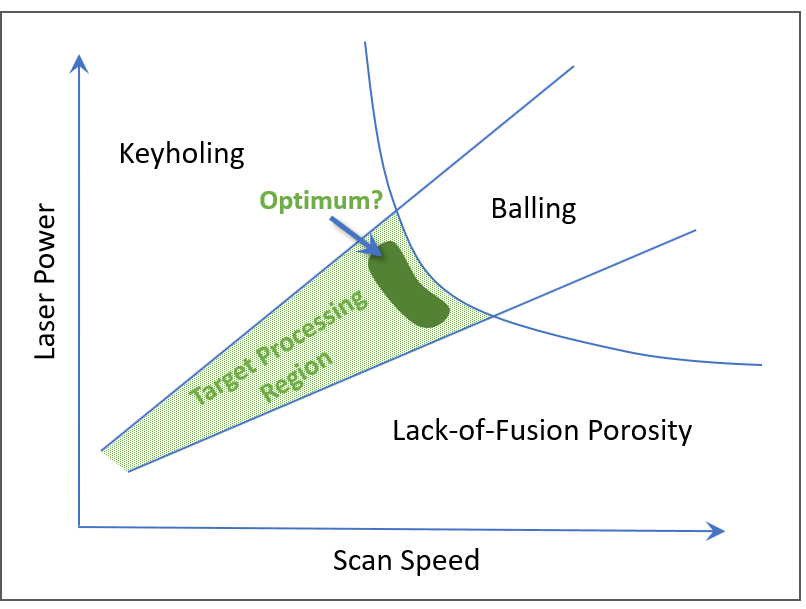

Let us now revisit the power/speed process map. In our single bead example, we made some assumptions about melt pool criteria that would yield good-candidate power/speed combinations based on hypothetical experimental data. Without the benefit of experimental data, however, it becomes a wide open exploration with many variables. The Additive application solves for only lack-of-fusion porosity. Accurate simulations of the other two porosity mechanisms (keyholing and balling) would require full fluids analyses and would consider the effects of other physics within the melt pool. Still, our software can guide you toward a more informed approach when choosing process parameters, and provide essential information about lack-of-fusion porosity, in particular.

As in Single Bead Parametric simulations, up to 300 permutations are possible for Porosity Parametric simulations. However, each permutation takes a much longer time to complete because, now, many layers are being simulated in the cuboid geometry, not just a single bead. The general approach is to select the best candidate process parameters as determined from the Single Bead Parametric simulation and introduce a new variable, such as Hatch Spacing.

Note: Porosity simulations require a considerable amount of hard drive space. See Guidelines for Managing Porosity Simulation Data before beginning a Porosity simulation.

![]()

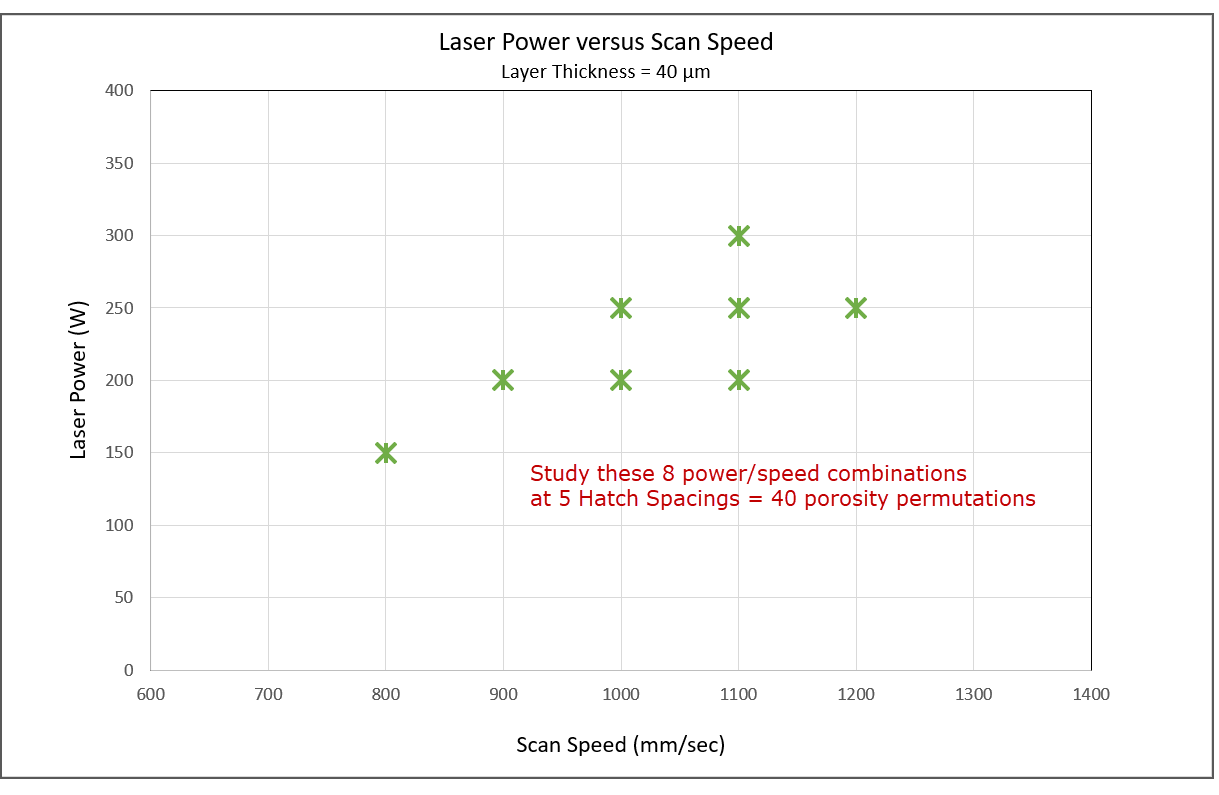

In our case study, we identified 8 target power/speed combinations to study further. If we introduce 5 hatch spacing values, we will have 40 porosity permutations.