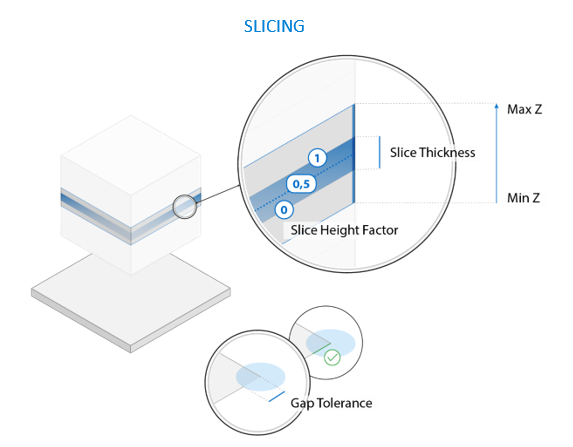

Slice Thickness: The thickness of the individual layers of metal powder.

Slice Height Factor: Identifies where the slice should be within the layer. A value of 0 represents the lowest area of a layer. A value of 0.5 represents half of the layer and a value of 1 represents the uppermost area of a layer.

Gap Tolerance: The maximum length of gaps between vectors. Gaps that are shorter than the defined value are closed automatically.

Use Limits. If enabled, you can define the Z-dimensions for

the part between which the slicing should take place. This means that only a restricted area

of the part is analyzed and time is saved, useful for test purposes, for example.

Use Limits. If enabled, you can define the Z-dimensions for

the part between which the slicing should take place. This means that only a restricted area

of the part is analyzed and time is saved, useful for test purposes, for example.

Min Z: The value on the Z-axis at which slicing should start.

Max Z: The value on the Z-axis at which slicing should stop. If specified, the AM machine will treat the Max Z layer as an up-skin layer. (The last layer is always an up-skin.)