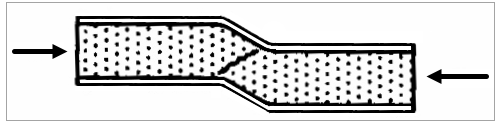

Although formulated as a local failure criterion, shear crimping describes a form of general overall buckling failure. It applies to cases where the wavelength of the buckles is very small if compared with global buckling because of low core shear modulus. The crimping of the sandwich occurs suddenly and usually causes the core to fail in shear at the crimp. It may also cause shear failure in the bond between the facing and core. This kind of failure often appears because of a post-buckled state (out-of-plane deformations) when out-of-plane forces appear due to the deformations.

The critical shear crimping load proposed by Vinson ([39]) is

(5–119) |

where

|

|

Vinson ([39]) assumed very thin face sheets so that their contribution to the critical shear crimping load can be disregarded. Experience shows that shear crimping can also occur in sandwich panels with relatively thick face sheets, especially in regions where the laminate stiffness changes abruptly or close to loadings. Therefore, other theories take the stiffness of the face sheets into account ([39]):

(5–120) |

where

The critical shear crimping load is sensitive towards imperfections as shown by Léotoing ([41]). So a slightly adjusted formulation is implemented in ACP which provides maximum flexibility to configure the criterion to take application and material specific characteristics into account.

(5–121) |

The shear crimping factors and

are derived from test data. The defaults for

and

are 1 and 0, respectively. So, by default, the critical shear crimping load

in ACP is equal to Equation 5–119 (Vinson) (for laminates where the face sheets

are much thinner than the core material). In case of

=

= 1, the predicted critical load is slightly different if compared with Equation 5–120 (Sullins), depending on the thickness ratio

between the face sheet and core.

For uniaxial compression the effort is:

(5–122) |

| where |

In the case of shear loading, the effort in Equation 5–122 is evaluated with respect to the principal

direction of loading. The material parameters of Equation 5–121 are rotated into the principal direction of

loading to get the allowable forces and

with respect to the first and second principal directions of loading.

In the case of biaxial compression, the failure condition of shear crimping is the sum of the efforts in the first and second loading direction:

(5–123) |

| where |

In general, it is recommended you validate the numerical results with experimental measurements because the shear crimping failure mode is sensitive to imperfections and local effects (stiffness changes, for example).