This simple example of a race car nose and wing demonstrates a possible workflow for composite analyses using variable material data, ACP draping simulation, and temperature dependence. Variable material data is used to simulate incomplete curing of the composite material in the model. Note that the wing geometry, composite lay-up, and material data are fictitious and should not be used in any real world analysis or application.

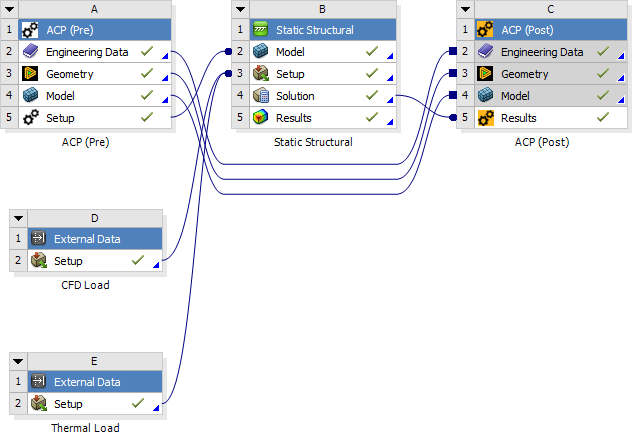

The following figure shows the Workbench setup. Cell D (External Data) contains the results of a Fluent analysis which provides the surface pressure distribution on the race car nose and wing. The composite lay-up, draping, and incomplete curing field are defined in ACP-Pre in cell A. Cell E (External Data) defines the temperature field. The structural effect of the airflow around the race car nose and wing are analyzed in cell B (Static Structural). Cell C (ACP-Post) contains the failure analysis of the composite race car nose and wing.

The model used in this example analysis is available by

downloading this

file.

The model used in this example analysis is available by

downloading this

file.

A general overview of using variable material data can be found in Variable Material Data in Composite Analyses.