Variable data for composite materials are configured in Engineering Data. The following properties can be functions of up to nine field variables:

Density

Elasticity parameters

Stress limits

Strain limits

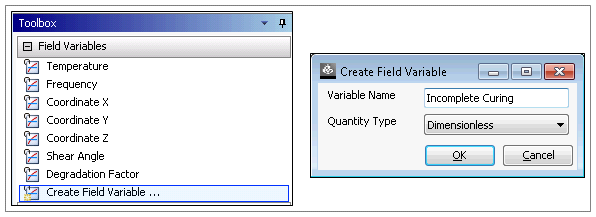

Temperature, Shear Angles and Degradation Factor are predefined field variables. User-defined field variables can also be created. In this example, the effect of incomplete curing across the parts is modeled. As a first step, the field variable Incomplete Curing is defined and specified as dimensionless. A value of 1.0 indicates perfect curing while a value of 0.0 indicates that no curing took place.

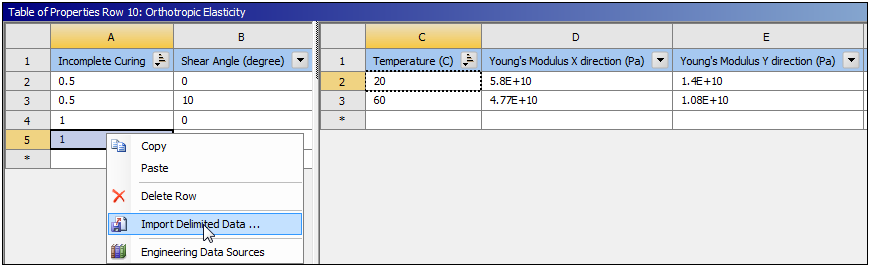

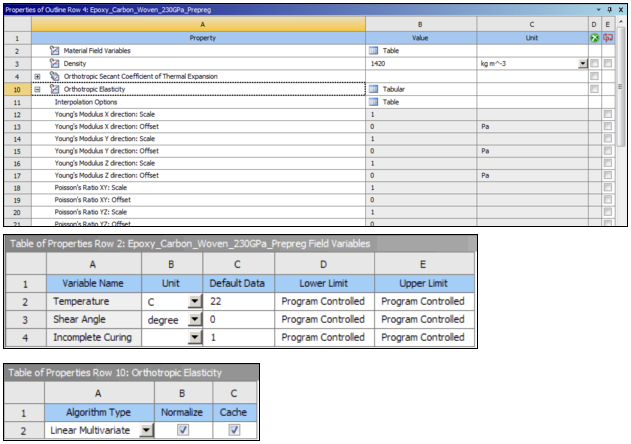

In the next step, the field variables are assigned to the material properties. Make the elasticity parameters of the Epoxy_Carbon_Woven_230GPa_Prepreg material a function of Temperature, Shear Angle, and Incomplete Curing. To accomplish this, select the material and then select the Orthotropic Elasticity property. Double-clicking a field variable assigns it to the Orthotropic Elasticity property. Fill the table for the Orthotropic Elasticity property by manually entering values or by importing a CSV file.

During finite element computations and postprocessing, the effective material properties are interpolated from these tables based on the local field variables state. The interpolation scheme can be controlled when selecting Interpolation Options. When selecting the Material Field Variables property, the unit, default data, lower, and upper limit can be set. The software suggests program controlled values for some of the options. The default data defines the assumed state of the field variable, if it is not specified in the model.

In this way, you can have full material specifications in Engineering Data, but only use a subset of the specified dependencies during the simulation. For more details, see ACP-Pre: Define Fields for Shear Angle, Degradation Factor, and User-Defined Field Variables.