The Butt Joint Sequence allows you to define butt joints between Modeling Plies. A butt joint consists of sequences (primary and secondary plies) which specify the lay-up on both sides of a butt joint. The Butt Joint Sequence object automatically detects where the selected plies join and generates butt joints instead of drop-offs.

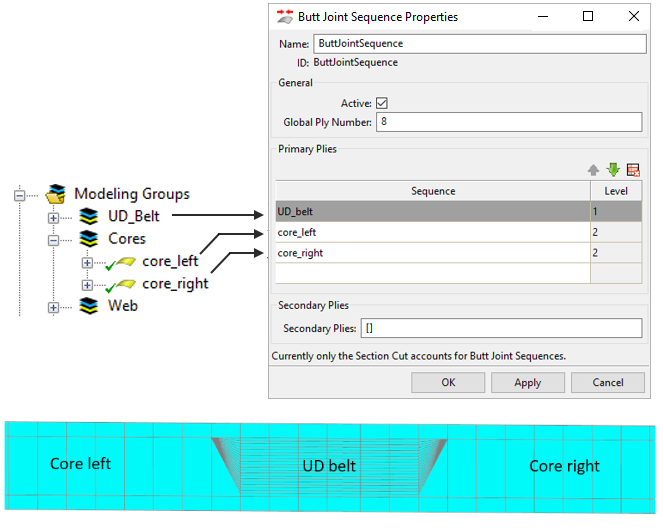

The Butt Joint Sequence Properties window contains the following options:

Active: Active plies are considered in an analysis. Inactive plies are present but not considered.

Global Ply Number: Defines the global ply order. By default, a new Sequence is added after the last one in the Modeling Group. The order of the Plies in the Modeling Groups is equal to this value.

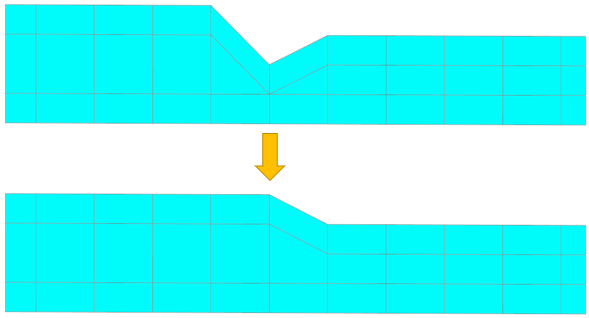

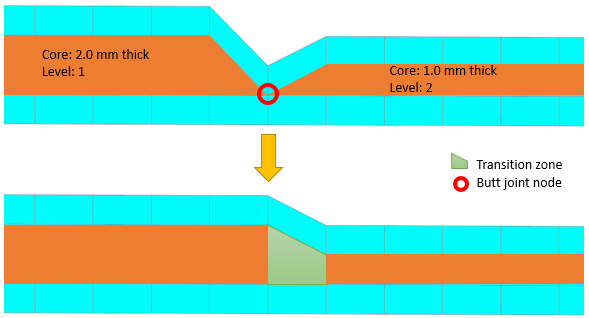

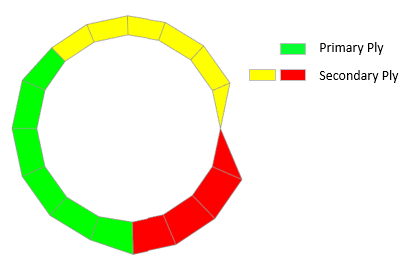

Primary Plies: Sequences which pass their thickness onto the other plies of a Butt Joint Sequence. A Primary Ply can be a Modeling Ply or a Modeling Group. The Level column specifies which sequence defines the thickness at a butt joint. The sequence with the lower level is dominant where the other sequence inherits the thickness. Potential differences in the thickness between the sequences are graduated over one element within the sequence with the higher level (the transition zone in the following image). No butt-joint is created between plies with equal level.

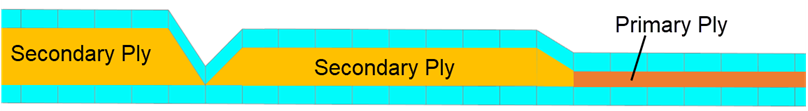

Secondary Plies: Secondary plies inherit the thickness from Primary Plies, but do not pass it further. So, drop-offs are generated where two secondary plies join.

In most cases, you can define a Butt Joint Sequence without the use of secondary plies. An example where secondary plies may be necessary would be a butt joint on a cylinder where you need drop-offs:

The following is a list of notes limitations of the Butt Joint Sequence:

A Modeling Ply can only be used in one Butt Joint Sequence

Butt Joint Sequences do not affect shell models. They are only considered in Section Cuts

Solid model extrusion does not consider butt joints

A Butt Joint Sequence can only be linked to Modeling Plies with a lower Global Ply Number.

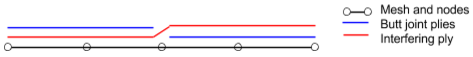

The butt joint can not be updated if a ply sequenced between the first and last ply of the butt joint covers the node where the plies join, shown in the following diagram:

Modeling groups may be easier to work with if a butt joint consists of a large number of plies