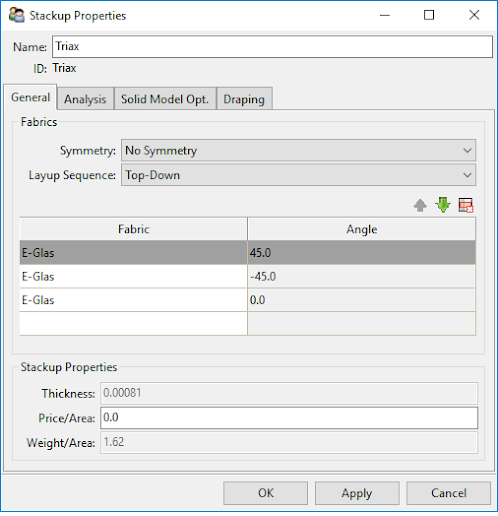

A stackup is a non-crimp fabric with a defined stacking sequence. From a production point of view, it is considered as one ply, which is applied on the form. For the analysis, all plies forming the stackup are considered. For every ply of the stackup, the fabric and its orientation must be given:

These stackups have different Price/Area and solid model options than a laminate of single plies. For this reason, Price/Area can be entered again. Stackups can be exported to an ESAComp XML file format and are converted to laminates in the process.

The definition of the stackup can be given in both directions (Bottom-Up and Top-Down). In the Top-Down sequence, the first defined ply (the first one in the list) is placed first on the mold and is the bottom of the stackup. The other plies are placed over it. During analysis, the sequence can be checked. In the above figure, the ply 45 direction is on top (see Figure 2.20: Stackup Properties - General).

For a quicker definition, the stackup can be defined with symmetries.

The Even Symmetry option defines the symmetry axis on the top of the sequence, and uses all plies.

In the Odd Symmetry option, the ply on the top is not used for the symmetry. So the middle of the top ply is the symmetry axis of the final sequence.

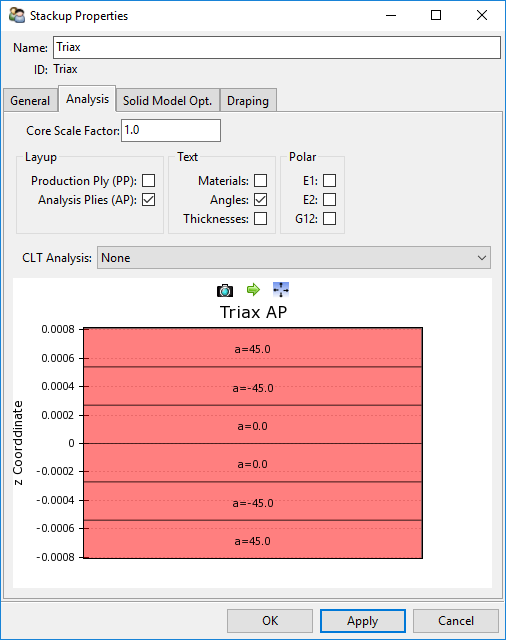

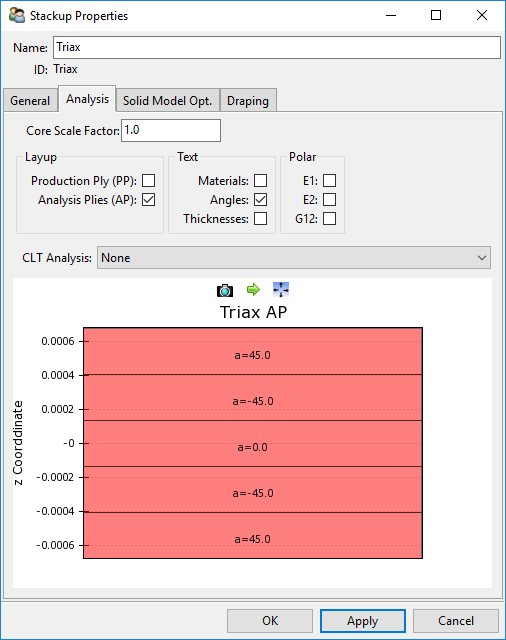

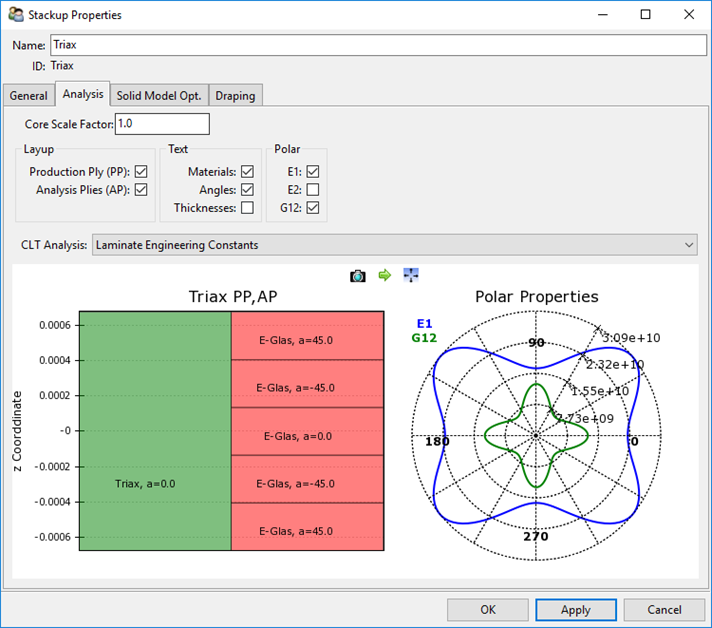

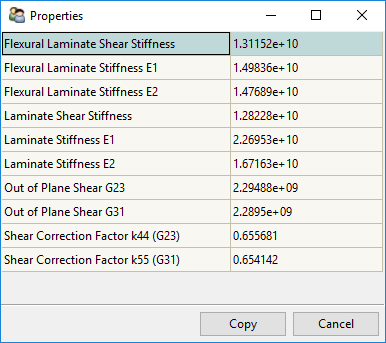

The Analysis tab provides evaluation of the laminate properties of the stackup, which can be plotted as graphical information.

This plot can be exported as a picture ( ) or as a

.csv file (

) or as a

.csv file ( ). It is

possible to translate and zoom into the lay-up

distribution with the mouse button. To come back to

a fit view, click

). It is

possible to translate and zoom into the lay-up

distribution with the mouse button. To come back to

a fit view, click  . In addition,

laminate properties (stiffness matrix or flexural

stiffness), which are based on Classical

Laminate Theory (CLT), can be

calculated.

. In addition,

laminate properties (stiffness matrix or flexural

stiffness), which are based on Classical

Laminate Theory (CLT), can be

calculated.

The following results based on Classical Laminate Theory can be calculated by selecting them from the CLT Analysis drop-down:

Laminate Stiffness and Compliance Matrices

Normalized Laminate Stiffness and Compliance Matrices

Laminate Engineering Constants

The material handling settings for Solid Models are identical for Fabrics and Stacks. For more information, see Fabric Solid Model Options.

The Draping settings are identical for Fabrics and Stacks. For more information, see Draping .