There are several different Puck Failure criteria, the following sections describe them.

The two oldest Puck failure criterion formulations are simple Puck and modified Puck. Both criteria consider failure due to longitudinal loads and matrix failure mode due to transverse and shear loads separately ([ 27 ] and [ 28 ]).

For both the simple and modified Puck criteria, failure in fiber direction is calculated the same way as in the maximum stress criterion:

(5–60) |

Matrix failure is calculated differently for each formulation as illustrated in Equation 5–61 for simple Puck. Equation 5–62 demonstrates how tensile or compressive failure stresses are used depending on the stress state.

(5–61) |

where:

(5–62) |

The modified Puck criterion differs from the simple criterion only in the formulation for matrix failure:

(5–63) |

As in Hashin Failure Criterion, the failure occurs

when either or

reaches one, so the failure criterion function

is:

(5–64) |

Despite being called simple in the failure criteria configuration in the Failure Criteria Definition dialog the Puck modified version is actually implemented. The name is referring to the simplicity of that criterion in comparison to Puck's Action Plane Strength Criterion.

The following sections describe the different failure modes for Puck’s action plane strength criterion.

As in the simple Puck criterion, one option for evaluating fiber failure is to use the maximum stress criterion for that case ([ 29 ], [ 30 ], and [ 31 ]):

(5–65) |

and similarly a maximum strain criterion:

(5–66) |

A more complicated version for FF criterion was presented by Puck for the World Wide Failure Exercise, but the maximum stress criterion is considered sufficient for the case of FF.

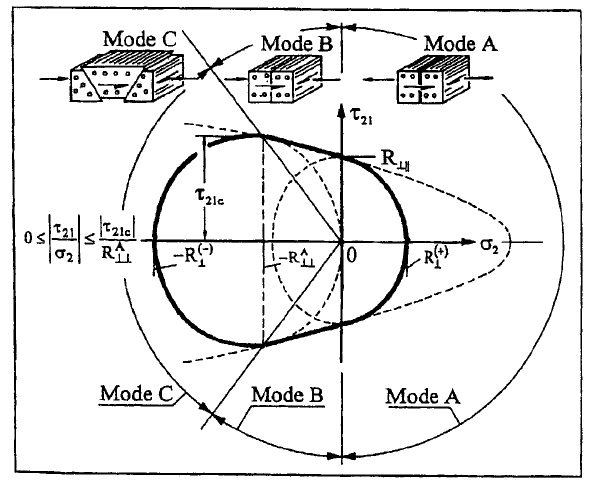

Interfiber failure is formulated differently depending on the model type.

Interfiber failure, or interfiber fracture ([

29

] and [

30

]) can be explained in the cutting plane for which the

principal stress of a UD layer is zero in the case

of plane stress.

The curve consists of two ellipses (modes

and

) and one

parabola (mode

). Generally Puck's action plane

strength criterion is formed utilizing the following 7 parameters,

, where

stands for fracture

resistances and

for slope parameters of the fracture

curves. The symbols

and

denote the

reference to direction parallel to the fibers and transverse (perpendicular)

to the fibers. The values for

and

define the intersections of the curve with

-axis,

as well as

for the intersection with

-axis.

The slope parameters

and

are the inclinations in the latter intersections.

The failure conditions for IFF are:

(5–67) |

The superscript denotes that the fracture resistance

belongs to the action plane.

(5–68) |

The assumption is valid here

and leads to:

(5–69) |

Equation 5–70 is also valid.

(5–70) |

As the failure criterion functions and the functions for their

corresponding stress exposure factors are the same, they can

be written as follows (given Equation 5–69 and Equation 5–70):

(5–71) |

While the latter formulations have been a reduced case working in ()-stress space, the 3D stress state can be described with Equation 5–72:

(5–72) |

where:

|

|

|

|

|

|

From the above equations, the failure criterion function is

formulated in the fracture (action) plane using the corresponding

stresses and strains. The formulations for the stresses ,

, and

in an arbitrary

plane with the inclination angle

are:

(5–73) |

To find the stress exposure factor the angle

is

iterated to find the global maximum, as the failure will occur for

that angle. An analytical solution for the fracture angle is only

available for plane stress-state by assuming:

(5–74) |

which leads to formulations for the exposure factor:

(5–75) |

Puck illustrated in [

29

] that the latter criterion can be used as a criterion to determine

delamination, if an additional weakening factor for the interface is applied, finally

resulting in:

(5–76) |

The active failure mode depends on the fraction angle and

the sign of

. Delamination can occur if

is

positive and

is 90 degree. The failure modes

and

happen

with negative

.

Different default values for the coefficients are set for carbon and glass fiber plies to:

| Carbon: |

| Glass: |

Those values are compliant with recommendations given in [ 32 ].

To take into account that some fibers might break already under

uniaxial loads much lower than loads which cause ultimate failure

(which can be seen as a kind of degradation), weakening factors can be introduced

for the strength parameters. Puck formulated a power law relation

in [

29

]:

(5–77) |

where and

and

can be can

be experimentally determined.

Different approaches exist to handle this problem numerically. The function given in Equation 5–77 can be replaced by an elliptic function:

(5–78) |

where:

|

|

|

|

In ACP, the stress exposure factor is calculated by intersecting the weakening factor ellipse with a straight line defined by the stress vector using the parameters:

|

|

|

|

|

|

|

|

Otherwise the fiber failure criterion determines the stress

exposure factor .

Default values for the degradation parameters are and

.