To create a variable material that depends on one or more parameters, click the Solve Variable Material icon under the Solve menu to perform the homogenization analysis. The resulting parameterized material will then be exported to Workbench.

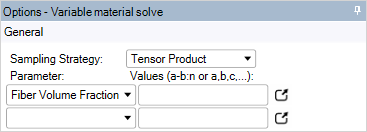

Sampling Strategy: Choose the sampling method. Two options are available:

Tensor Product: All possible parameter combinations are sampled. For instance, if you sample Fiber Volume Fraction at 0.4, 0.5, and 0.6 and the Temperature at 20 C and 100 C, then the following six design points are evaluated:

Fiber Volume Fraction 0.4 0.4 0.5 0.5 0.6 0.6 Temperature 20 C 100 C 20 C 100C 20 C 100 C Custom: Specify exactly which parameter combinations you want sampled. For instance:

Fiber Volume Fraction 0.4 0.5 0.5 0.6 Temperature 20 C 20 C 100 C 40 C For this sampling strategy, the number of sampling points per parameter must be equal, as each value corresponds to one design point.

When you select a Short Fiber Composite Model, you can generate a predefined sampling strategy using the Short Fiber Wizard.

Parameter: Select the parameter and set the values to be sampled. Click the

icon to open a

dialog box where you can edit the values more easily. For the values, you

can specify either:

icon to open a

dialog box where you can edit the values more easily. For the values, you

can specify either:A comma separated list. For instance, 0.2,0.4,0.7.

The start and end value as well as the number of sample points. For instance, 0.2-0.7:6 corresponds to 0.2,0.3,0.4,0.5,0.6,0.7.

Note: When specifying the parameter values, you must use a dot when expressing decimals, even if the Windows number format is set to using the comma as the decimal delimiter.

The parameters that can be varied are geometry parameters (for example, Fiber Volume Fraction, Shear Angle, etc.) and the Temperature. Temperature is shown only if any of the constituent materials is temperature dependent.

Note: You should specify Temperature as the last parameter because then the geometry and mesh update can be skipped in some cases (namely when the same geometry is solved more than once consecutively).

The following properties are available only for homogenization using the finite element method:

Number of Samples per Design Point: The number of samples generated for each combination of parameter values (only for randomized RVEs).

Seed: The seed number used to generate the seeds for each RVE (only for randomized RVEs).

Continue after Failed Evaluation: If an update of an RVE fails, continue with the evaluation of the next RVE.

Keep Scdocs of Failed RVE Evaluations Open: If you wish to investigate a failed RVE update, this option will keep the corresponding document open after a failure.

File Handling: Choose how to proceed with generated files.

Note:

The Material Designer opens new documents to evaluate the variable material.

If Continue after failed evaluation is active and some of the evaluations fail, then the Variable Material Evaluation is in a partially up-to-date state (indicated by an orange check-mark). You can continue with the generation of the material.

In addition, you can also try to redo the failed evaluations by choosing Recompute Failed in the context menu.