Often, for an injection molding process, the exact properties of the constituent materials are not known. Furthermore, the choice of reaction and bonding agents influences the resin's underlying properties, and the mixing process induces deviations of the fiber aspect ratio from its nominal value. Because of these factors, some of the constituent properties can only be obtained by reverse engineering from experimental data.

In Material Designer, you can calibrate the Young's modulus of the matrix material and the aspect ratio of the fibers based on the elastic response of the composite. For Analytical Short Fiber Composite Models, you can use the following procedure (assuming you already created an experimental Dataset as described in the previous section):

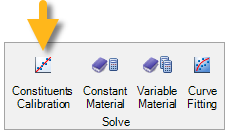

Add a Constituents Calibration analysis from the Ribbon Bar.

In the Constituents Calibration Options dialog, select the Dataset(s) of interest and specify the range of variation for the Young's modulus of the matrix material and the aspect ratio of the fibers. You will find further details in Constituents Calibration for Short Fiber Analytical Models in the Material Designer User's Guide.

When the calibration is complete, you can review the computed material properties and assess the fit quality in the Results panel.