Speos Direct Optimization with Ansys DesignXplorer

Direct Optimization allows you to automate the optimization of a system.

Ansys DesignXplorer is a powerful application in Ansys Workbench for studying and optimizing a Speos design starting from Speos input and output parameters.

The application uses a deterministic method based on Design of Experiments (DOE) and several optimization methods including Direct Optimization.

Direct Optimization is a goal-driven optimization system that generates arrays of design points and finds out solutions candidates. Responses can be studied, quantified, and graphed in Ansys Workbench.

Presentation

Direct Optimization allows you to automate the search of the best candidate values to reach a desired result.

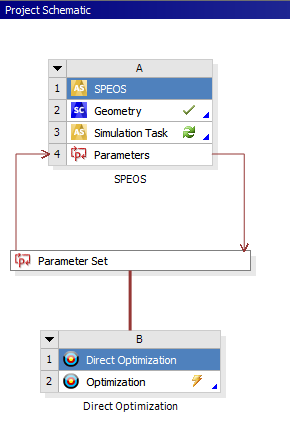

To create a Direct Optimization system, drag the system from the Toolbox and drop it under the Speos system so that the parameters are automatically linked.

Optimization Process

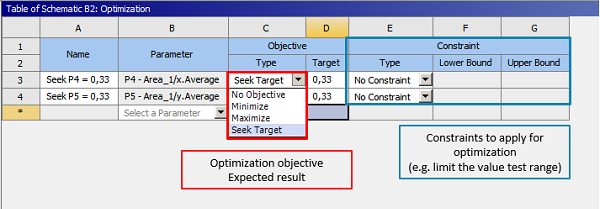

A target or an action to be performed on the results is defined. You can ask the optimizer to seek a target (define a target value to reach), maximize or minimize a result.

To reduce the optimizer field of action, you can also define constraints like an upper and/or a lower bound to limit the field of measure.

The system will then basically compute and test out a large number of configurations and parameters set to find the best candidate values to reach the defined target.

To compute these configurations, the optimizer creates design points with specific parameters set.

At the end of the computation, the best candidate values to reach the expected result are selected.