Maxwell to Ansys Thermal Coupling

Coupling Maxwell 2D/3D with Ansys applications is supported via the Workbench schematic. Thermal feedback is supported for Maxwell magnetostatic, eddy current, AC and DC conduction, and transient types. Users also need to set up the design and geometry appropriately. An appropriate design should be temperature-dependent, and have one or more solve setups that are enabled for thermal feedback.

Maxwell-Specific Considerations

- If there is thermal feedback, each frequency point in an eddy current sweep will be solved with the same feed-back data.

- Temperature distribution data that has already been exported from Ansys Thermal will be invalidated when users continue the Maxwell solution in a way such that the Maxwell mesh is being regenerated.

- Once the Maxwell solution has been integrated with a thermal effect, the adaptive process of a static simulation will be disabled. Users must then manually invalidate the temperature data in the existing solution before the adaptive process will be re-enabled.

- Maxwell solutions can incorporate feedback from both thermal and stress.

- When setting up loss transfers from Maxwell to WorkBench, if the user wants to map loss density on a face shared by two objects, this face only has to be used once in the setup.

Maxwell 2D Coupling Considerations

For Maxwell 2D in RZ mode, geometry either must be exported into the XY plane, or the geometry must be rotated into the XY plane after it is imported into Ansys Mechanical. This is because Mechanical 2D requires geometry to be in XY plane.

There are two modes in Ansys Thermal 2D. The default mode is called Planed Stress where zero stress and non-zero strain are assumed in the z-direction. This is similar to the XY mode in Maxwell 2D. The other mode is called Axisymmetric. This mode will be used when a 3D model can be generated by revolving a 2D section 360 degree. This is similar to the RZ mode in Maxwell 2D. Users must ensure that they use the correct geometry mode in Thermal 2D. Invalid geometry mode selection is prohibited by the Thermal2D interface.

There are two types of Import Load in Mechanical: Heat Generation and Heat Flux. Heat Generation is used when mapping losses from objects in Maxwell 2D/3D and Heat Flux should be used to map the loss from the edges of objects in Maxwell 2D/3D. Heat Flux is supported only for eddy current designs with impedance boundary. Users can insert multiple Heat Generation or Heat Flux loads via the Imported Load (Maxwell 2D/3DSolution) objects.

Convergence of Maxwell-Mechanical Two-Way Thermal Coupling

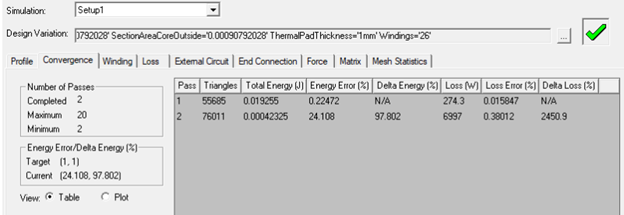

In two-way thermal coupling between the Maxwell static solver (magnetostatic, eddy, AC, DC) and the Mechanical thermal solver, the user may be confused by the Loss value reported in the solution profile (see figure below): when two-way coupling is finished, the difference of the Loss value between the last pass and previous pass is sometimes huge and is NOT aligned with Loss Error(%). The uncertainty arises as to whether the two-way coupling process has truly converged.

The convergence reported in the solution profile primarily reflects the convergence history in mesh refinement, aiming for a field solution independent of mesh size. This mesh refinement process occurs within the AEDT environment.

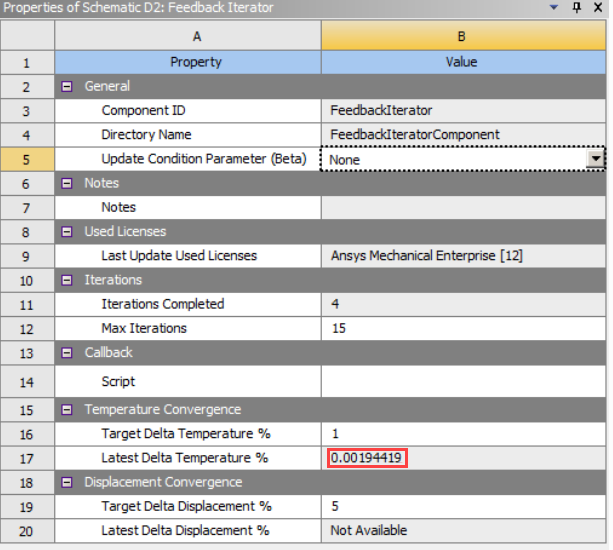

Instead of relying on the convergence reported in the Maxwell solution profile, users should focus on examining properties of the Feedback Iterator in the Workbench:

The true convergence of the two-way thermal coupling process implies the attainment of a steady temperature field and steady loss distribution in Maxwell. The mesh refinement process serves as a preprocessing step for the Maxwell static solvers. In two-way thermal coupling feedback iterations, the mesh in Maxwell solver remains unchanged, but the Maxwell field solution is changing because the material properties are temperature dependent, which affect the solution profile of the last pass.