Layers in Band Mesh (Maxwell 3D Magnetostatic and Transient)

Maxwell rotating machine models need very precise cloned mesh to get accurate estimates of cogging torque. Thus, the mesh near the interface of the static side and moving side, i.e., band surface, is crucial to the accuracy of this simulation result.

Clone mesh is an initial mesh process and currently provides one layer mesh between band and stator and one layer mesh between band and rotor. However, one layer may not provide sufficient accuracy for some designs. For such cases, multiple layers in band for clone mesh can be used to improve accuracy. By assigning this mesh operation, you can control the number of layers near the band on both the static and the moving side without losing the repeatability of the clone mesh.

Example

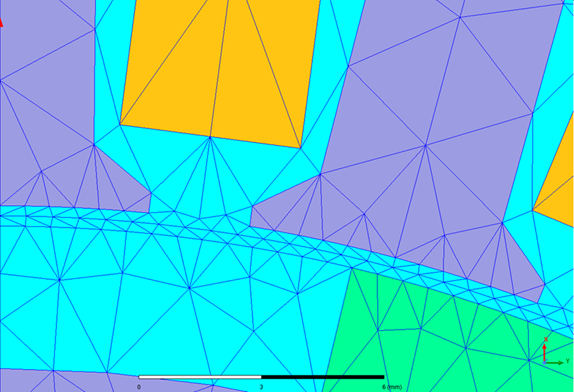

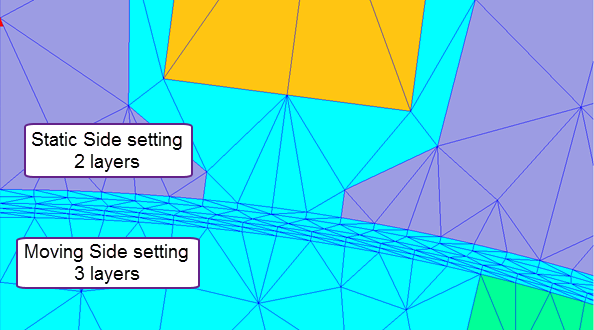

Without multiple layers in the band mesh, when the model is cloned, the static side has clone geometry for which clone mesh is provided. The moving side does not have clone geometry so sweeping mesh is provided for it. This simple mesh type is shown below.

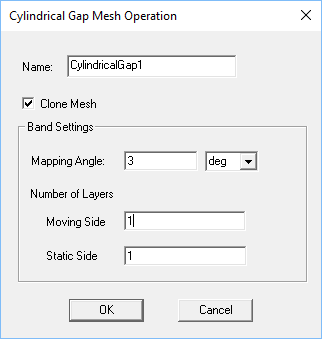

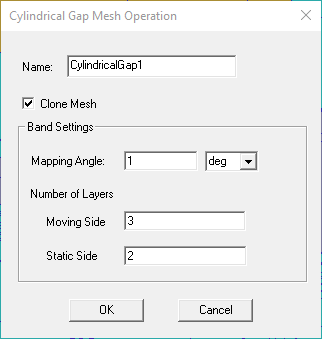

To improve accuracy of results, multiple layers can be specified for a Clone Mesh in the Band Settings section of the Cylindrical Gap Mesh Operation dialog box.

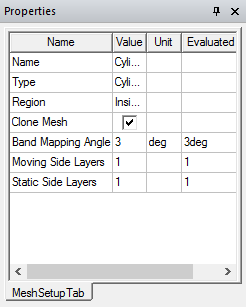

The layers options are also available in the Properties window Mesh Setup Tab when the cylindrical gap mesh operation is selected in the project tree.

By setting the Number of Layers for the Moving Side and/or the Static Side to integer values greater than 1, the number of band layer meshes will be increased accordingly.

Considerations and Limitations

-

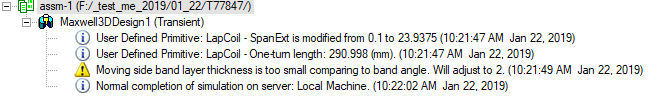

If you specified a number of layers that would result in a lowering of mesh quality, clone mesh will adjust the number of layers, and give a warning message similar to the following:

- If the model it not suitable for clone mesh, or if clone mesh fails to mesh it, this setting will not be respected in TAU regular 3D mesh. A warning message will be given by mesh in this situation.

-

Post processing seeding refinement will respect the layers in the mesh. Adding any post processing mesh operation will not destroy the layers; however, the clone mesh might be destroyed.

Related Topics

Assigning Cylindrical Gap Treatment