Using Design of Experiments

Design of Experiments (DOE) is a technique used to scientifically determine the location of sampling points and is included as part of the Response Surface, Goal Driven Optimization, and Analysis systems. Design of Experiments plus a mathematical approximation of output parameters lets you:

- Reduce the number of simulations

- Interactively explore the design space before running optimization

Design of Experiments describes the relationship between the design variables and the performance of the product by using Design of Experiments (DOE), combined with response surfaces. DOE and response surfaces provide all of the information required to achieve Simulation Driven Product Development. Once the variation of the performance with respect to the design variables is known, it becomes easy to understand and identify all changes required to meet the requirements for the product.

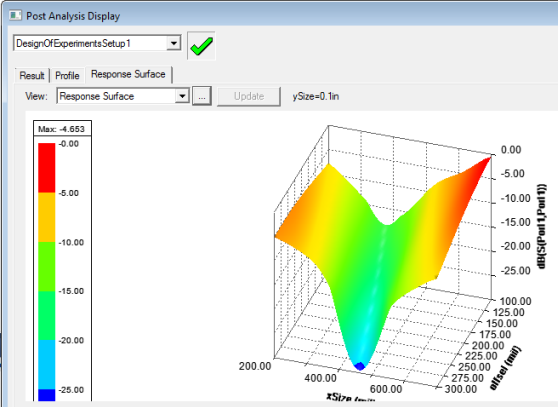

The goal is to create a response surface by interpolating through calculated points (a best curve fit). For each design, you can create a response surface for each output parameter. Once the response surfaces are created, you can share the information can in easily understandable terms: curves, surfaces, sensitivities, etc. They can be used at any time during the development of the product without requiring additional simulations to test a new configuration.

The Design of Experiments feature is integrated inside Electronics Desktop. Combined with Electronics Desktop‘s distributed solve feature, you can build the response surfaces from the DOE variation table much faster.

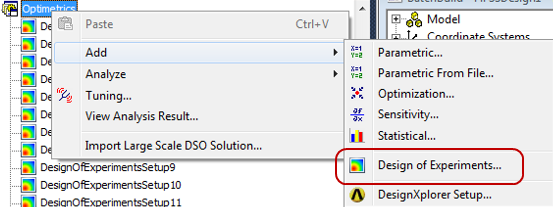

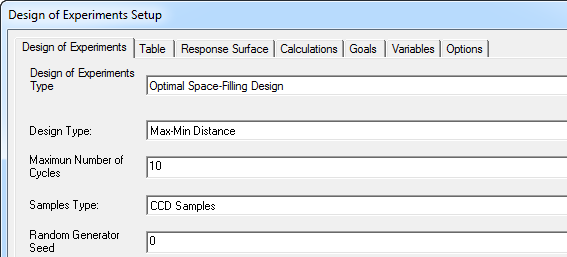

Selecting a Design of Experiments under Optimization opens a dialog with several tabs:

In the Design of Experiments setup, you select the DOE type, select the Response Surface, specify goals, view and include variables.

There are a wide range of DOE algorithms or methods available in engineering literature. These techniques all have one common characteristic: they try to locate the sampling points such that the space of random input parameters is explored in the most efficient way, or obtain the required information with a minimum of sampling points. Sample points in efficient locations only reduce the required number of sampling points and increases the accuracy of the response surface generated. For more information on the available types of DOE, see Design of Experiments Types.

Once you have set up your input parameters, you can update the DOE, which submits the generated design points to the analysis system for solution. Design points are solved simultaneously if the analysis system is set up to do so; sequentially, if not. After the solution is complete, you can update the Response Surface cell, which generates response surfaces for each output parameter based on the data in the generated design points.

Requirements and recommendations regarding the number of input parameters vary according to DOE type. For more information, see Number of Input Parameters for DOE Types.

If you change the Design of Experiments type after doing an initial analysis and preview the Design of Experiments Table, any design points generated for the new algorithm that are the same as design points solved for a previous algorithm will appear as up-to-date. Only the design points that are different from any previously submitted design points need to be solved.

You should set up your DOE Properties before generating your DOE Design Point matrix. The following topics describe setting up and solving your Design of Experiments, and viewing the results.