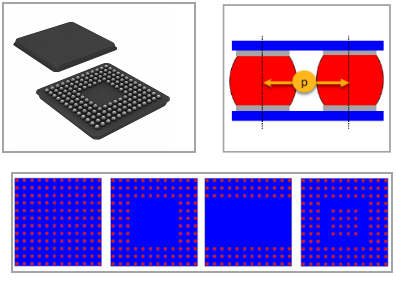

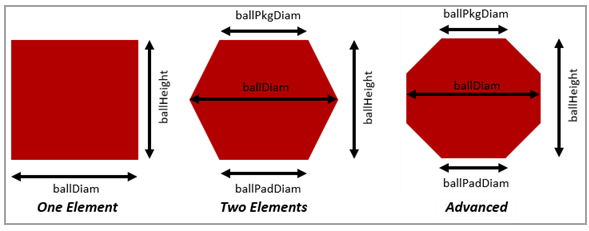

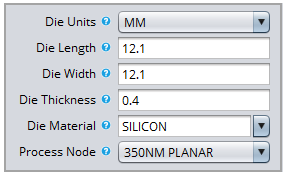

Ball Pattern: Refer to part data

sheet drawing. Ball Count: Refer to part data sheet

drawing. Ball Pitch: Refer to part data sheet

drawing. Ball Diameter: Refer to part data

sheet drawing. Ball Package Diameter: Refer to part

data sheet drawing. Ball Pad Diameter: Refer to part

data sheet drawing.

Tip: Often, data sheets do not provide Ball

Package Diameter or Pad

Diameter. As an approximation, use 90% of

the Ball Diameter.

Ball Height: Refer to part data sheet

drawing.

Tip:For Ball Height, use

max dimension, not

nominal. Datasheet dimensions for solder balls show the

geometry of the loose component before reflow with

solder paste. Add 70 to

100 μm to the stated ball

height. For larger BGAs (40 x

40 mm), the high mass of the

component will cause the solder balls to collapse

slightly, so this edit is not needed.

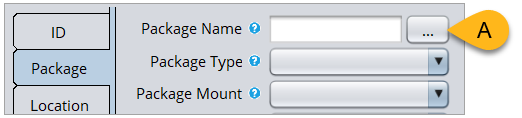

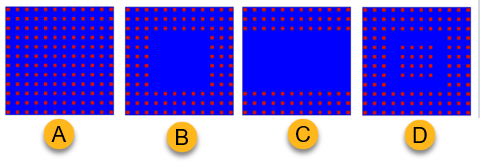

For Ball Grid Layout Properties (Ball Chan

Width, Ball Modeling,

Ball Perimeter Rows, Ball

Perimeter Cols, Ball Island

Rows, Ball Island Cols),

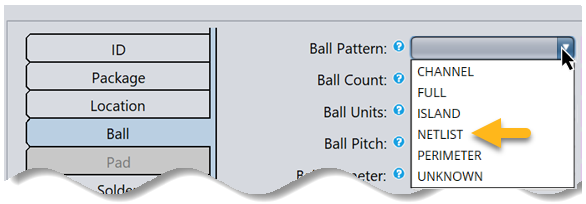

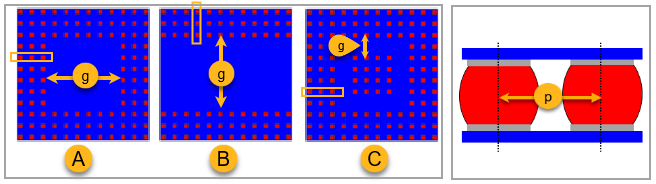

refer to the datasheet drawing, and see notes below. Ball layouts often come in standard patterns that

are defined in Sherlock: FULL

(A, below), PERIMETER (B),

CHANNEL (C), or

ISLAND (D). For non-standard layouts, the

NETLIST

Ball Pattern option will

extract ball location information from the PCB

design files. NETLIST will

also correctly populate ball locations for standard

grid layouts. To correctly populate Ball Chan

Width, Rows, and

Columns for standard BGA

layouts, remember: Ball Channel Width

applies only to Perimeter

(A in the image below),

Channel (B), and

Island (C) patterns.

To Calculate Ball Channel

Width

| Ball Channel Width = [ball pitch] x [the

number of ball columns on one side of the

gap] |

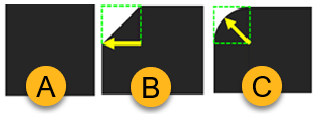

Tip: In some cases, setting the correct ball

pattern properties can be confusing. To confirm

your work is correct, view the component in

Sherlock's 3D Viewer to verify the accuracy of the

model. See Checking Your Work.

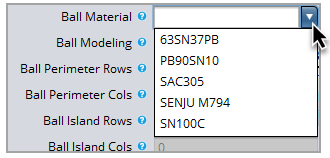

Ball Material: Refer to the part data

sheet. Ball Material is the type of

solder ball used to connect the BGA to the PCB. Supported

values are defined in the solder data file provided by

Sherlock and/or a user-defined data file.

Tip: BGA components may be assembled with solder balls

composed of a different alloy than what was selected for

the PCB solder paste.

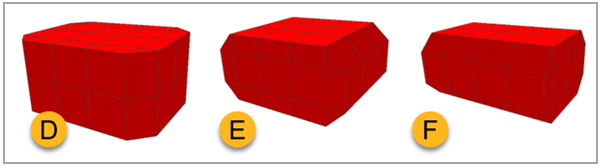

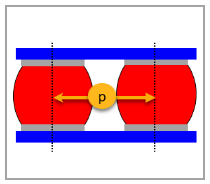

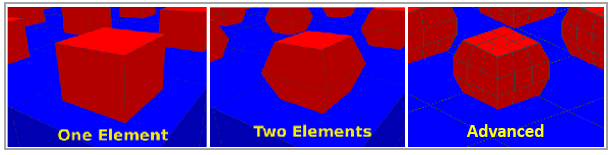

Ball Modeling:

NONE, ONE

ELEMENT, TWO ELEMENT,

or ADVANCED. For a detailed

discussion on ball modeling types, see Solder Ball Modeling in the Sherlock User's Guide.

|