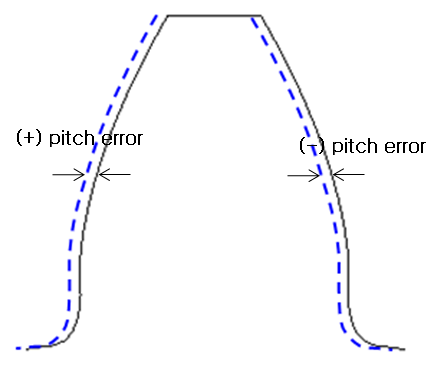

The deviation between actual measured pitch value between any adjacent teeth and the theoretical circular pitch at the mean cone distance. Motion Drivetrain provide a single pitch error method by each flank.

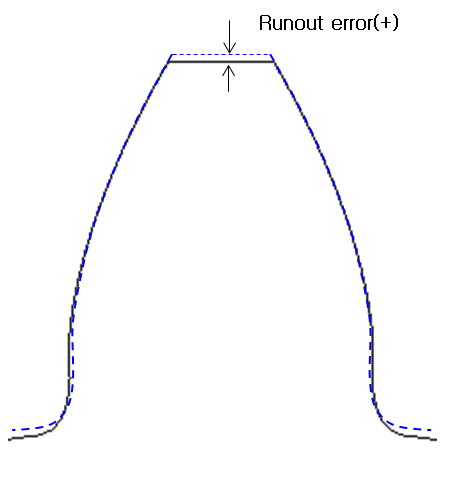

This is the maximum amount of tooth runout in the radial direction, measured by indicating a pin or ball placed between two teeth at the central cone distance.

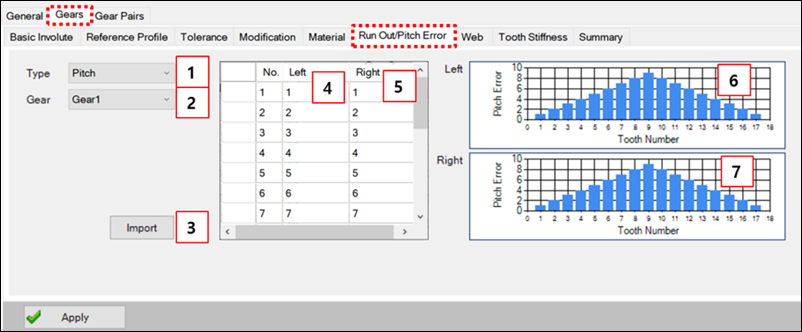

Figure 14.168: Parameters in Run Out/Pitch Error tab

| Parameter | Description |

Dimension (Range) |

| 1. Type |

Use to set a tolerance type. - Pitch - Runout | N/A |

| 2. Gear | Use to set the target gear. | N/A |

| 3. Import |

User can use a data file for tolerance. The file format is as following. (Pitch error) - First column : Gear tooth number - Second column : Left flank error - Third column : Right flank error (Runout error) - First column : Gear tooth number - Second column : Runout error | N/A |

| 4. Data grid(Left) | Use to set left flank tolerance. | N/A |

| 5. Data grid(Right) | Use to set right flank tolerance. | N/A |

| 6. Graph(Left) | Show amount of left tolerance by using chart. | N/A |

| 7. Graph(Right) | Show amount of right tolerance by using chart | N/A |