The following sections of this chapter are:

- 2.1. Computing Aerodynamic Coefficients on an ONERA M6 Wing at a Range of Angles of Attack

- 2.2. Computing Aerodynamic Coefficients and Wall Heat Flux on a Re- Entry Capsule at Different Altitudes in Earth and Mars Atmospheres Using Mixtures

- 2.3. Introduction to Component Groups on a CRM Aircraft at Different Flight Altitudes and Engine Regimes

- 2.4. Mesh Adaptation on a Subsonic/Transonic CRM Wing With Engine On

- 2.5. Computing Aerodynamic Coefficients on an Aircraft Horizontal Tail Wing in a Wind Tunnel Domain at Different Mass Flow Rates

- 2.6. Fluent Aero AET – Creating a VBM Input File for Blade Sections

The objective of this tutorial is to use Fluent Aero™ to obtain lift, drag and moment coefficients on an ONERA M6 swept wing geometry at a range of angles of attack. This part of the tutorial will focus on using the Fluent Aero graphical user interface to complete the setup, calculation and post processing of the multiple design points in the simulation.

Download the fluent_aero_tutorial.zip file here .

Unzip fluent_aero_tutorial.zip to your working directory.

Extract the oneram6-wing.msh.h5 file and the reference_data folder for this tutorial. The reference_data folder contains several .csv formatted text files. Their content will be compared to the CFD results of the current calculation. The reference data files are provided for demonstration purposes only.

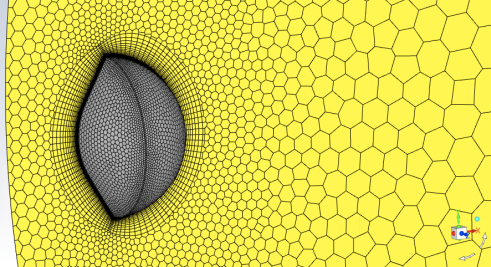

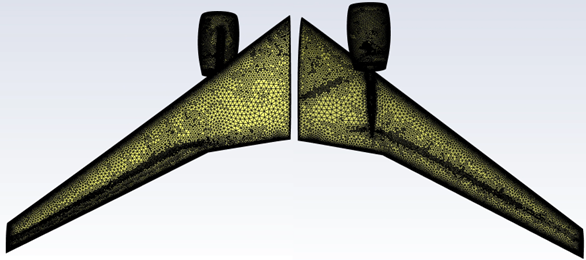

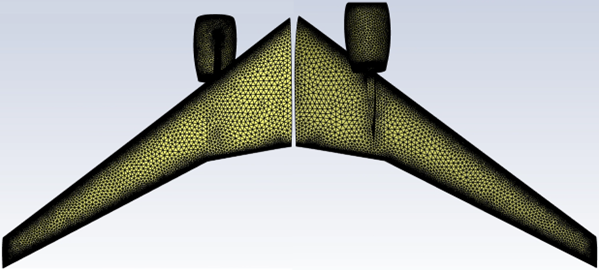

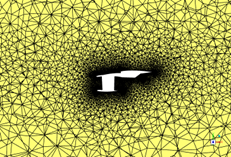

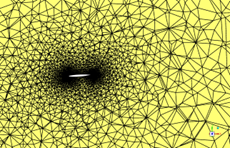

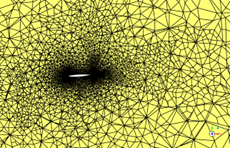

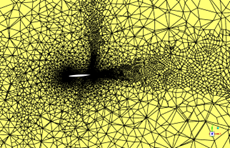

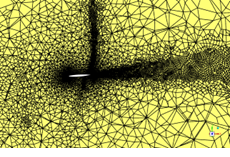

The oneram6-wing.msh.h5 file contains a grid of an ONERA-M6 swept wing that is an all-poly mesh and consists of 478,848 nodes, and 114,219 cells. This is a very coarse grid. Its purpose is to ease calculation time and resources while demonstrating the most common features of Fluent Aero. Four layers of prisms are grown off the wing’s wall boundaries and are used to capture the boundary layer. This number is insufficient if the goal is to obtain precise and accurate solutions. The limits of the computational domain are defined by a hemispherical boundary that acts as a pressure-farfield, and a flat circular boundary defined as a symmetry plane in the Z direction. This mesh follows the Freestream domain type requirements of a Fluent Aero simulation. For a Freestream domain type, the external boundary of the domain should be defined with a pressure-far-field zone, and can optionally include a connected pressure-outlet zone. Refer Freestream or WindTunnel Domain Type Requirements for more information.

Launch Fluent™ 2025 R2 on your computer. On the Fluent Launcher panel, set the Capacity Level to . Then select Aero. Set the number of Solver Processes to

4-8. Click .Alternatively, Fluent Aero can be opened using the aero (on Linux) or aero.bat (on Windows) file inside the fluent/bin/ folder.

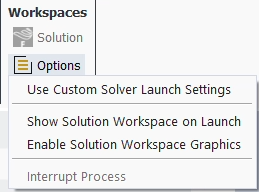

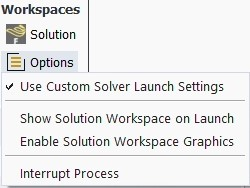

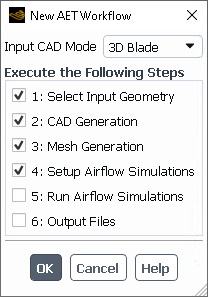

In the Fluent Aero workspace, go to the Project ribbon. Click Workspaces → , and make sure to uncheck , , and .

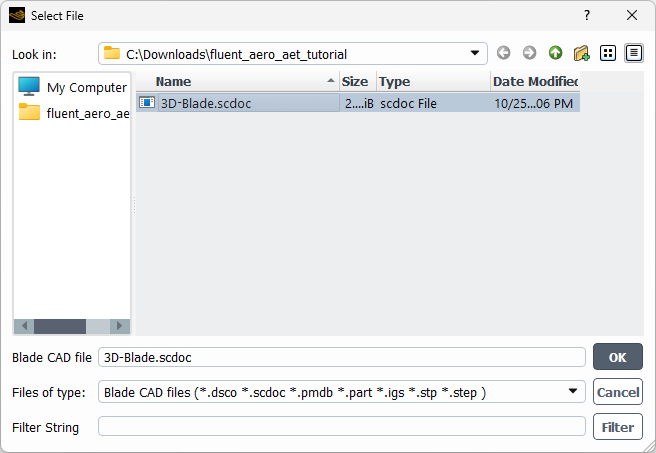

In the Project ribbon panel, select Project → and enter

Fluent_Aero_Tutorial_01to create a new project folder.In the Project ribbon, select Simulation → , and browse to and select the oneram6-wing.msh.h5 file. A New Simulation window will appear. Enter the Name of the New Simulation as

oneram6-aoa-exploration, and check . Click .

The case file will open and a background solver session will load. A new simulation folder will be created in your project folder. Fluent Aero will convert the .msh.h5 grid file to a .cas.h5 format case file and the latter will be imported in the simulation folder as oneram6-wing.cas.h5.

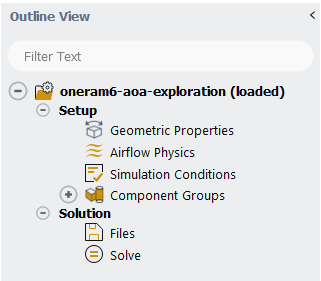

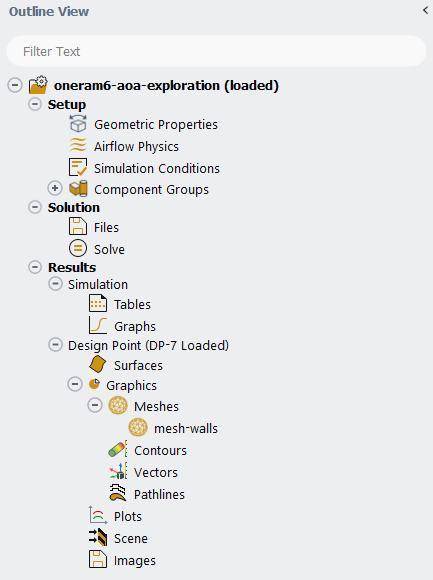

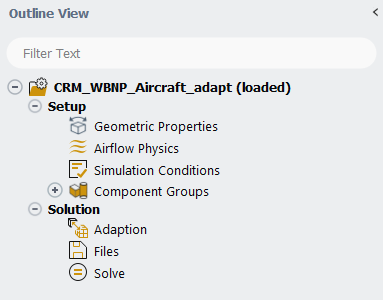

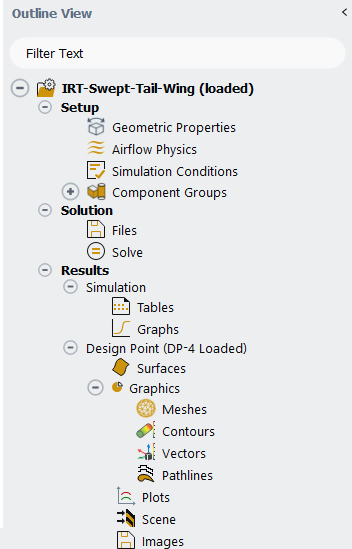

After the .cas.h5 file has been successfully loaded, a new Outline View tree appears under oneram6_aoa_exploration (loaded).

While importing, Fluent Aero will search for and find the pressure-far-field zone that defines the external boundary of the domain. If present, this will cause Fluent Aero to determine that this case is using a domain type, and the following message will be reported in the Console.

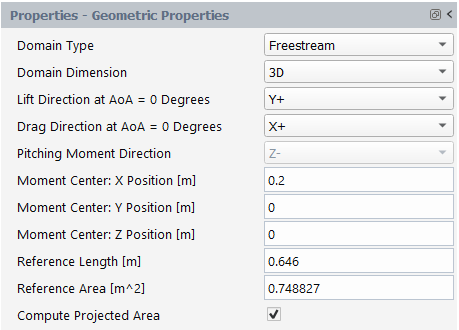

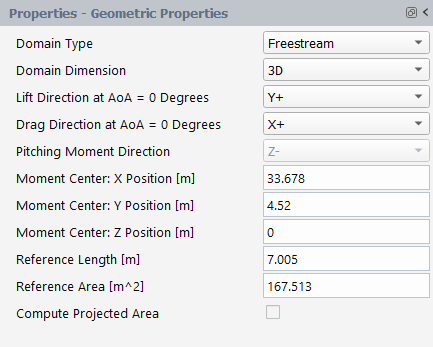

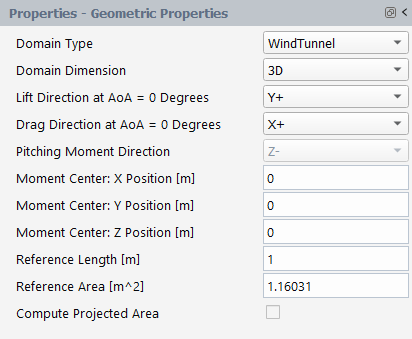

In the Outline View window, click Geometric Properties. A Properties - Geometric Properties window appears below the Outline View window. At the top of this new properties window, notice that the Domain Type has been automatically set to .

Define the orientation of the geometry within the computational domain, which will be used to compute the aerodynamic forces.

Set Domain Dimension to .

Set Lift Direction at AoA = 0 Degrees to .

Set Drag Direction at AoA = 0 Degrees to .

Set the Moment Center X, Y and Z Position [m] to

0.2,0, and0, respectively.Set the Reference Length [m] to

0.646, which corresponds to the mean chord length.Set the Reference Area [m^2] to

0.748827.

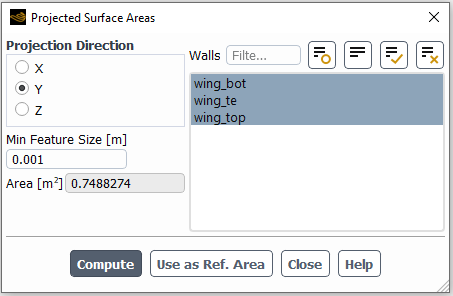

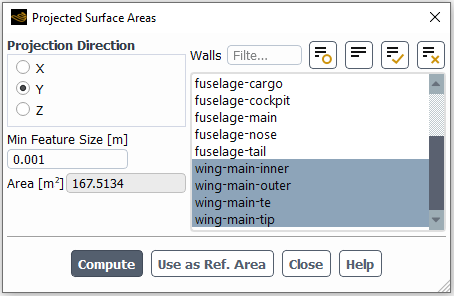

Alternatively, the reference area can be computed by enabling the option. A Projected Surface Areas dialog will appear. Set the Projection Direction to and select all wall surfaces. Click the button and then click the button to copy the computed area to the Reference Area [m^2] box.

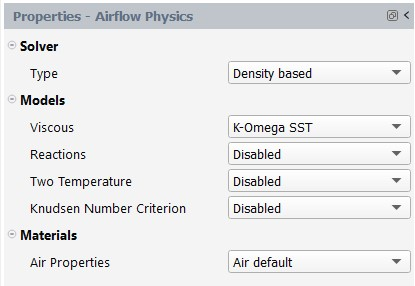

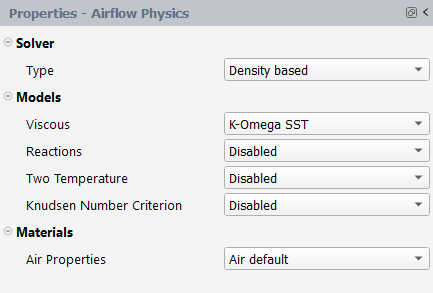

In the Setup tree, go to Airflow Physics. A Properties – Airflow Physics window appears below the Outline View window.

In the Solver section:

Set Type to .

In the Models section:

Set Viscous to .

Set Reactions to .

Set Two Temperature to .

Set Knudsen Number Criterion to .

In the Materials section:

Set Air Properties to .

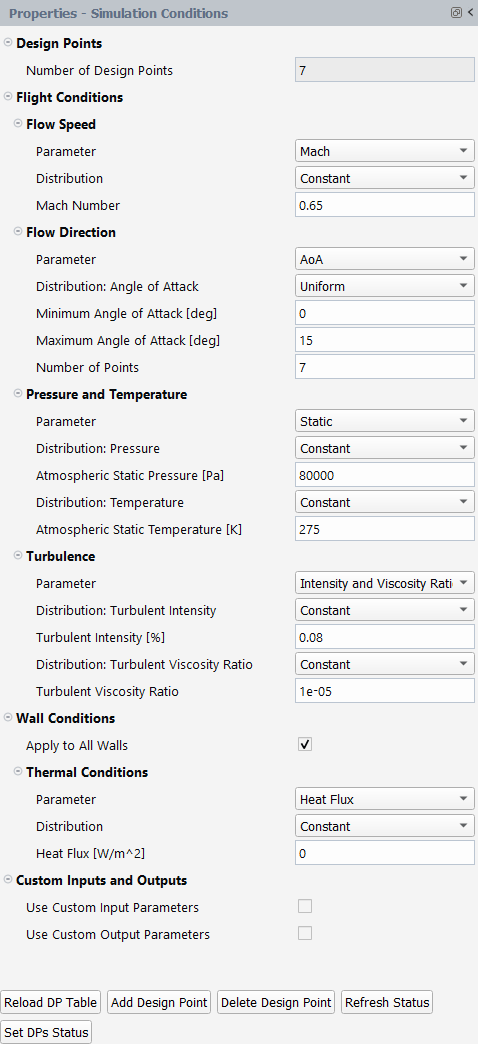

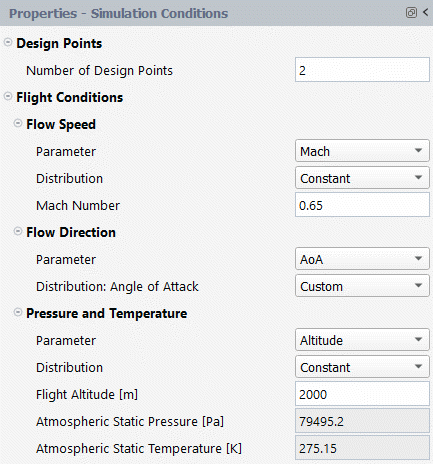

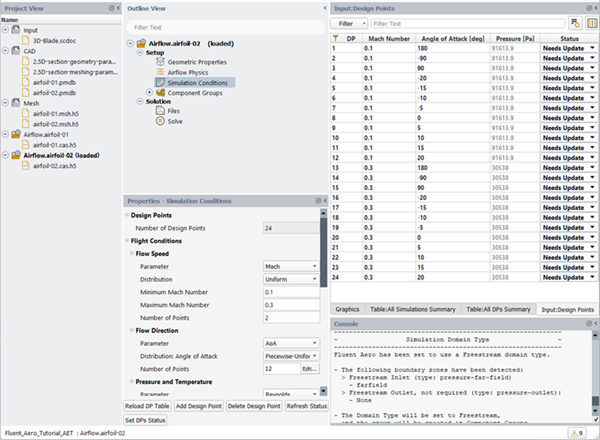

In the Setup tree, go to Simulation Conditions. In the Properties – Simulation Conditions window, go to Flight Conditions.

In the Flow Speed section:

Set Parameter to .

Set Distribution to .

Set the Mach Number to

0.65.

In the Flow Direction section:

Set Parameter to .

Set Distribution: Angle of Attack to .

Set the Minimum Angle of Attack [deg] to

0.Set the Maximum Angle of Attack [deg] to

15.Set the Number of Points to

7.

In the Pressure and Temperature section:

Set Parameter to .

Set Distribution: Pressure to .

Set the Atmospheric Static Pressure [Pa] to

80000.Set Distribution: Temperature to .

Set the Atmospheric Static Temperature [K] to

275.

In the Turbulence section:

Set Parameter to .

Set both Distribution: Turbulent Intensity and Distribution: Turbulent Viscosity Ratio to .

Set Turbulent Intensity [%] to

0.08.Set Turbulent Viscosity Ratio to

1e-5.

In the Wall Conditions section:

Enable .

In the Thermal Conditions section:

Set Parameter to .

Set Distribution to .

Set Heat Flux [W/m2] to

0.

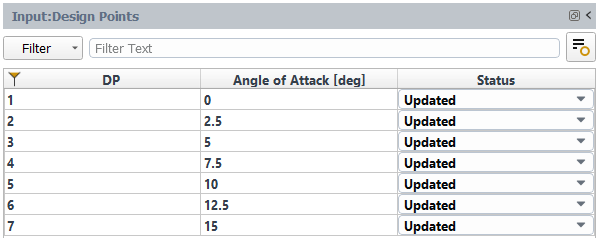

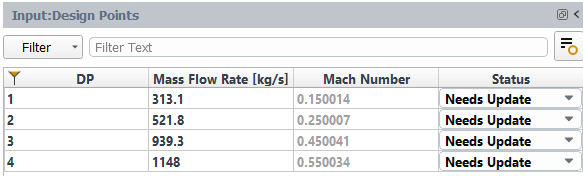

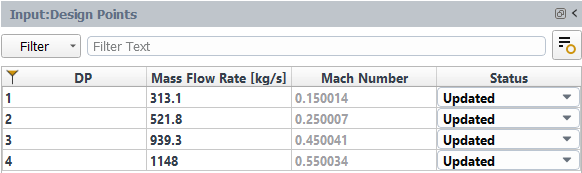

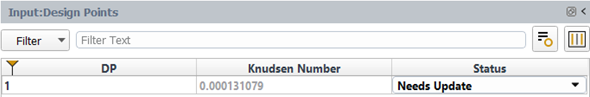

An Input:Design Points table will be created in the Graphics window on the right-hand side of the user interface. This table shows all the design points that will be simulated. The initial status of each design points (DP) has been set as . The status can be set as if you decide not to update one or several design points. In this tutorial, you will keep all design points as .

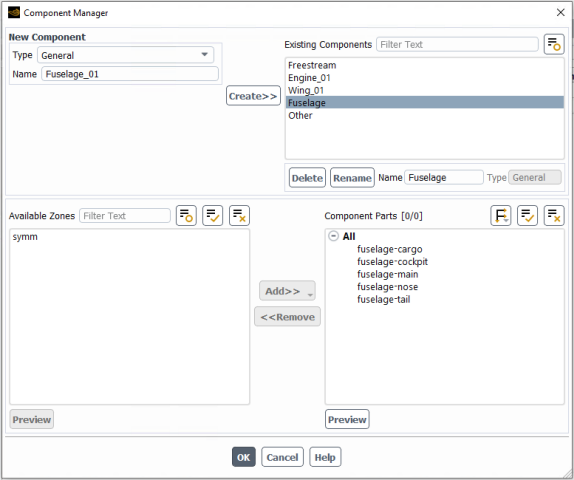

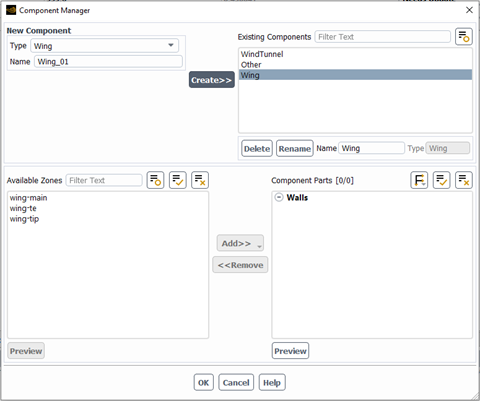

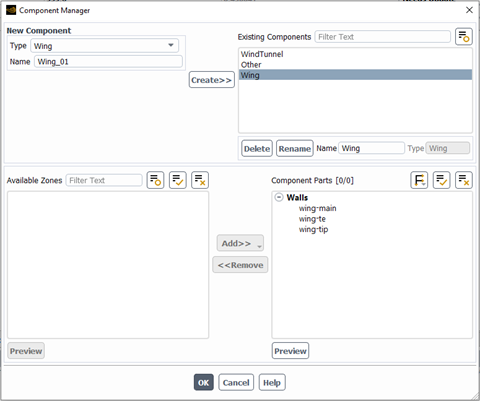

Go to Component Groups. Two default Component Groups have been created after the simulation is loaded.

The group contains the pressure-far-field zone that defines the external boundary of the domain and is where the freestream atmospheric flight conditions for each design point are defined as boundary conditions.

The Other group contains the remainder of the boundary zones which are the walls of the oneram6 wing geometry and the symmetry plane of the simulation domain.

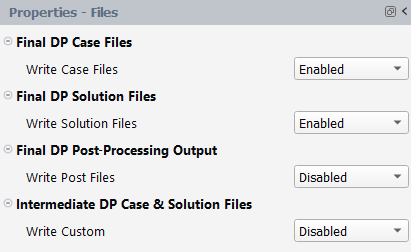

In the Outline View, go to Solution → Files. This step allows you to control the output files written per design point. Keep the default options.

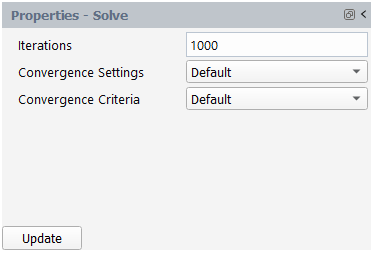

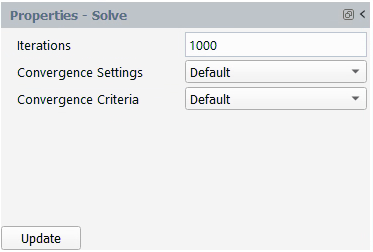

Under Solve, keep the default number of Iterations of

1000. Keep both Convergence Settings and Convergence Criteria as .

Click the button at the bottom of the Properties - Solve panel.

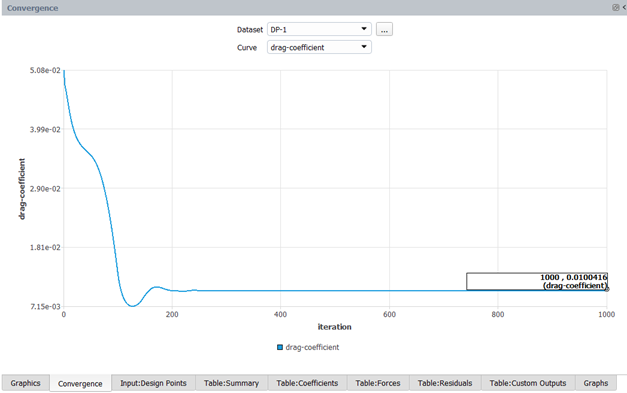

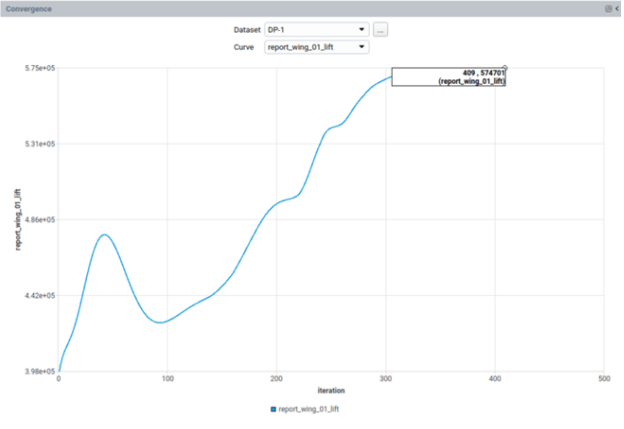

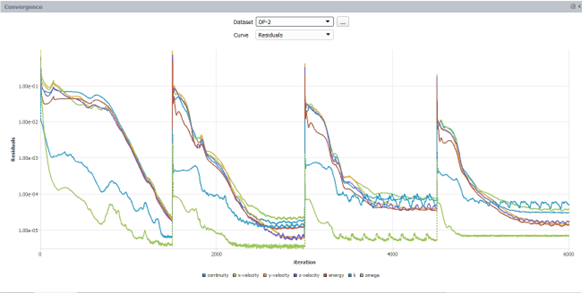

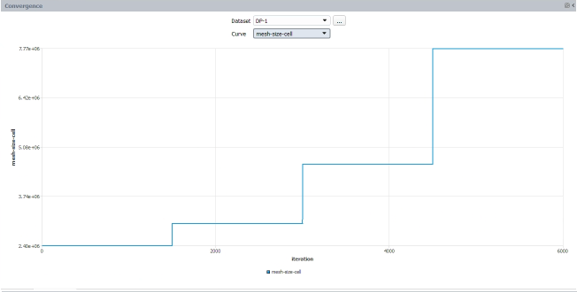

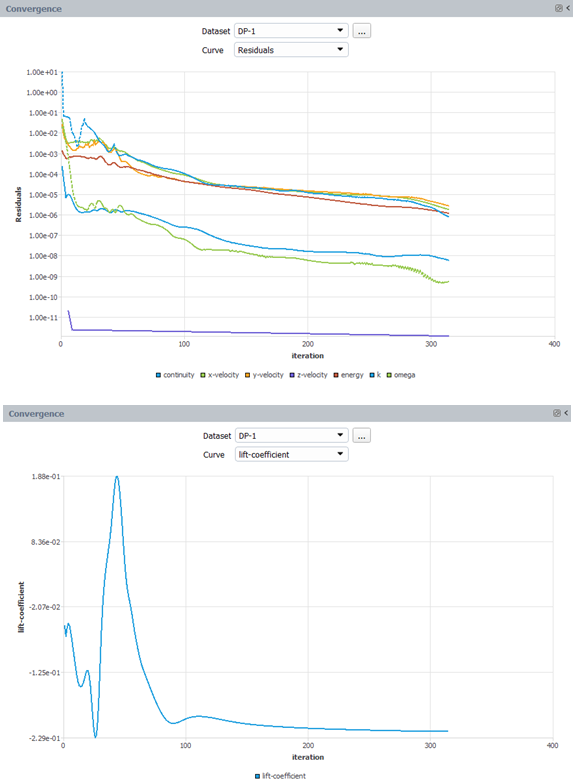

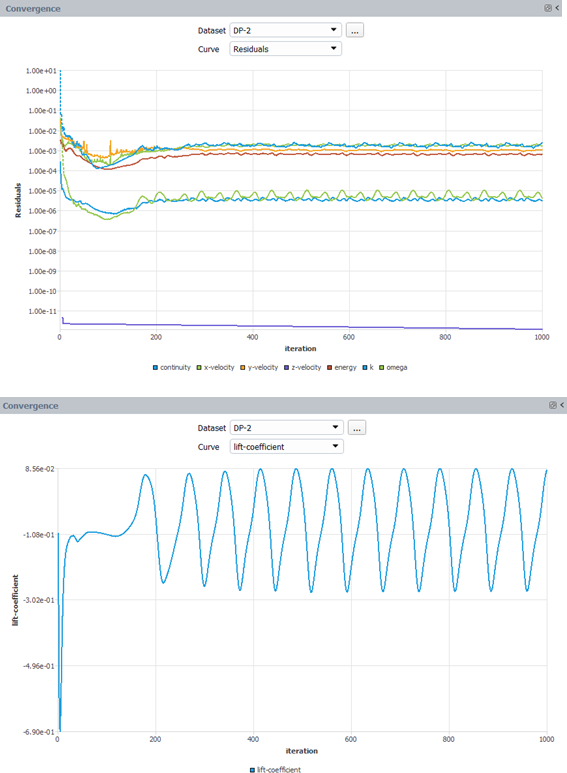

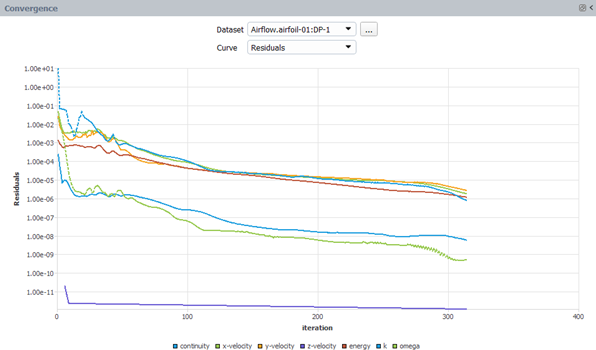

The calculation will start, and the first design point, DP-1, featuring the minimum Angle of Attack, will be simulated. A Convergence window will appear in place of the Graphics window and display the residuals and monitors for DP-1.

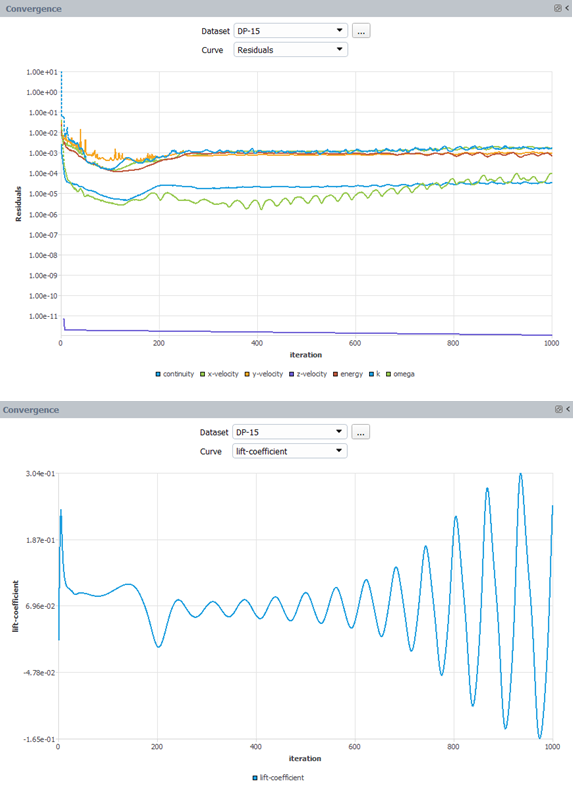

Design point DP-1 will calculate until the total Iterations (1000) or the Residuals Convergence Cutoff (1e-5) and Aero Coeff Conv. Cutoff (2e-5) are reached, whichever comes first. In this example, DP-1 will calculate for about

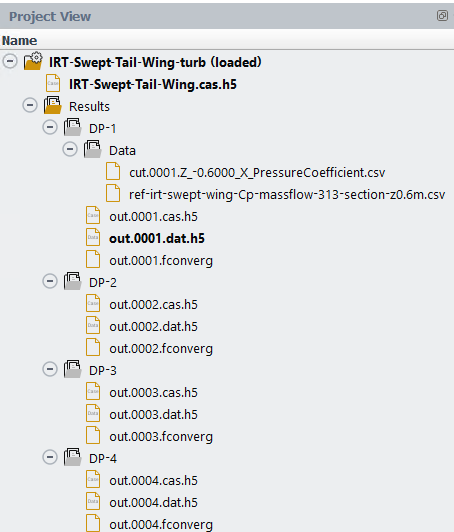

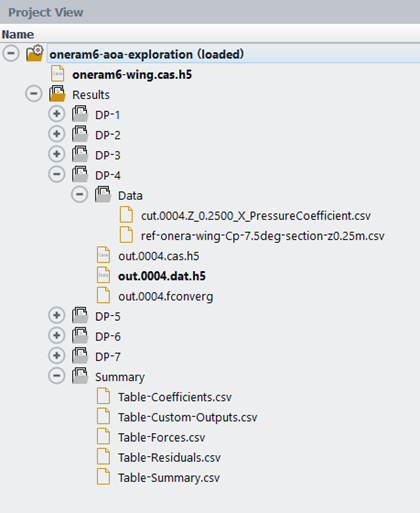

350iterations. At that point, the Angle of Attack will be updated for the next design point and the calculation will resume. This process repeats until all design points are simulated.Moreover, in the Project View, a Results folder will be created after the calculation starts. A folder for each design point along with an associated case file, data file, and convergence file will appear inside the Results folder.

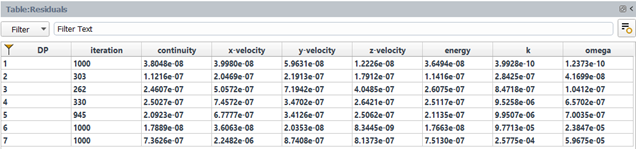

Examine the simulation's convergence history in the Convergence window, which is located on the right side of your screen. Set the Dataset to and the Curve to , to view the continuity, x-, y-, z-velocity, energy, and turbulence residuals for the first design point. You can left-click a residual curve to show the iteration number and the corresponding residual value. Here, the residual y-velocity at iteration 1000 is shown and equals to 5.90306e-8. The calculation has ended after reaching the maximum number of iterations.

Note: While all residuals in the image above meet the residual convergence cutoff criterion of 1e-5, it is still recommended for you to investigate your solutions to ensure that appropriate convergence levels have been achieved and that convergence remains stable. A residual convergence cutoff of 1e-5 may be appropriate for some cases, but not for others, and therefore care should be taken when selecting this value. If a stricter convergence criterion is required, you can go to Solve, change Convergence Criteria to and set a lower value (

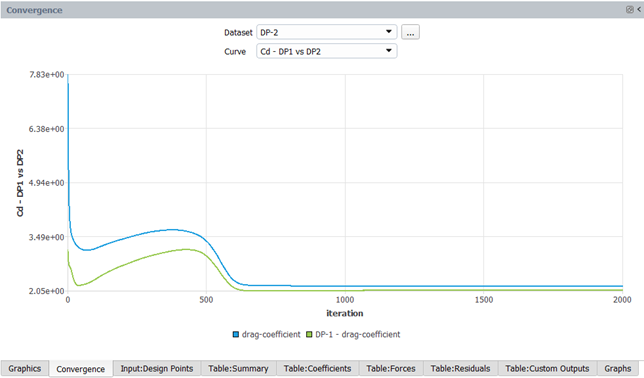

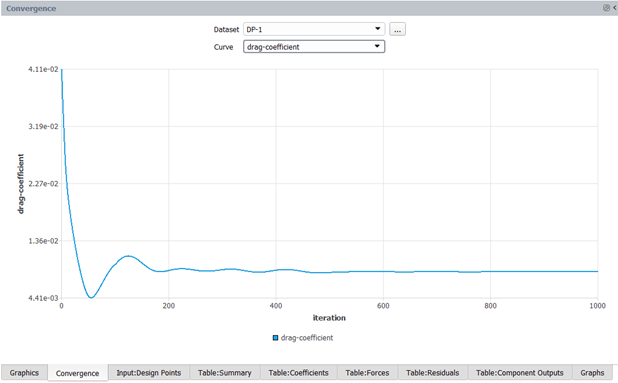

1e-6for example) next to Residuals Convergence Cutoff.In the Convergence window, set Curve to . The evolution of the drag coefficient for DP-1 will be displayed. Left-click the last iteration of the drag-coefficient plot, to show the drag coefficient value.

When the calculation of DP-1 is complete, the status column in row 1 of the Input:Design Points table will be set to , and the calculation of DP-2 will begin.

After all the design points have been updated, the status of the Input:Design Points table will be set to for all the design points.

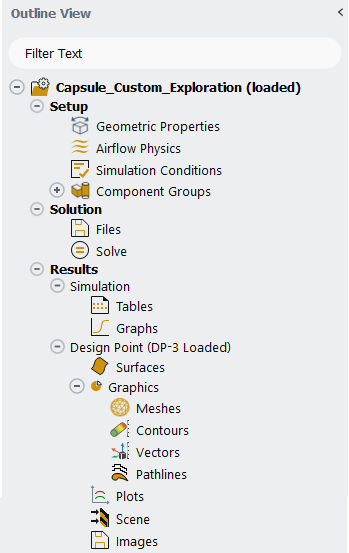

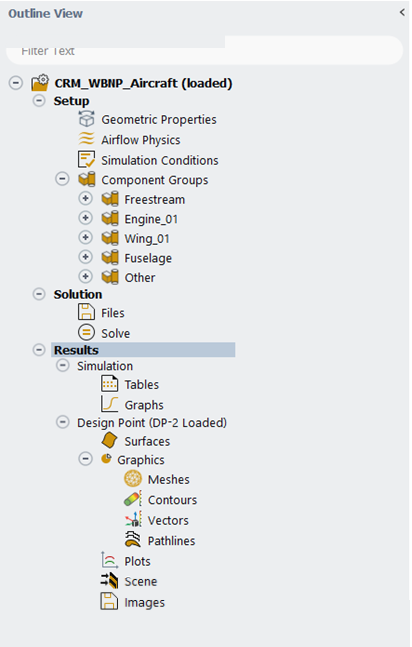

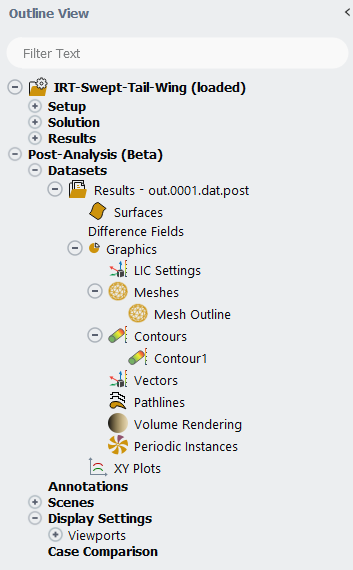

A Results node will be displayed in the Outline View tree after the simulation starts. The Results node contains a Simulation and Design Point (DP-# Loaded) sub-components. This allows you to quickly post-process design point solutions, by obtaining aerodynamic coefficient plots, creating contour plots of solution fields, comparing solution fields to experimental data, and more.

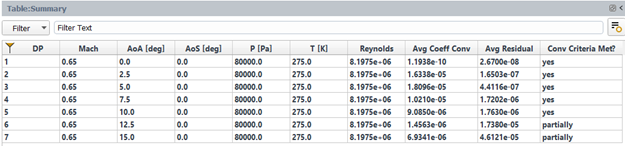

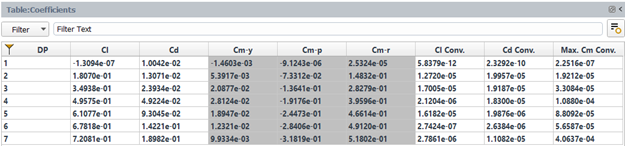

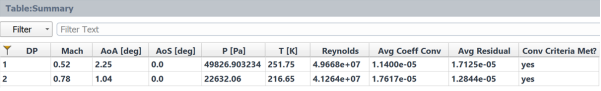

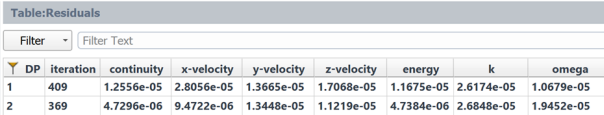

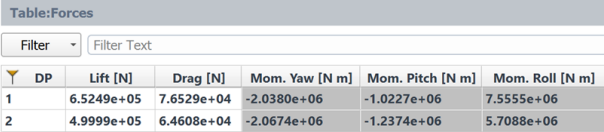

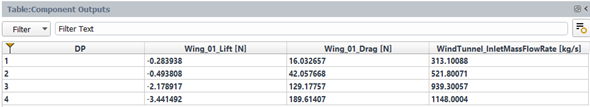

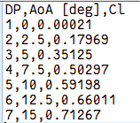

Go to the Simulation node. This node provides a comprehensive view of aerodynamic coefficients across all design points. The first element in the Simulation node is Tables. In the current tutorial, four different tables will be created automatically in the Graphics window area when the calculation is complete.

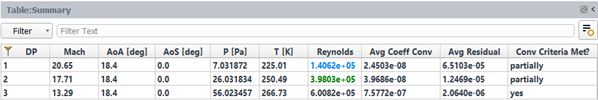

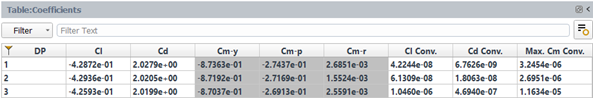

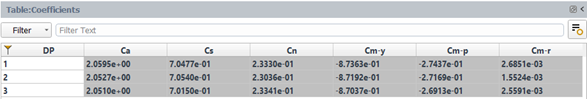

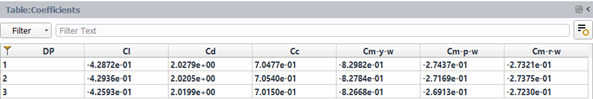

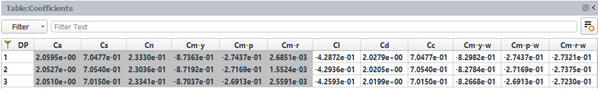

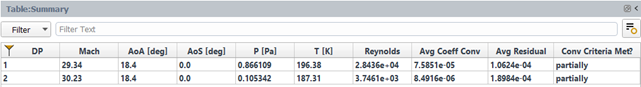

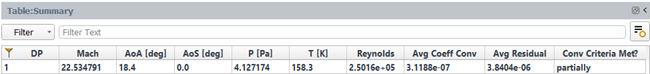

Click the Table:Summary, Table:Coefficients, Table:Forces and Table:Residuals tabs at the bottom of the Graphics window to reveal each table.

Table:Summary summarizes the flight conditions and convergence information for each design point. In the current simulation, most design points have met or partially met the convergence criteria.

Note: Depending on the number of CPUs used to calculate the design points, there may be some differences in the convergence achieved.

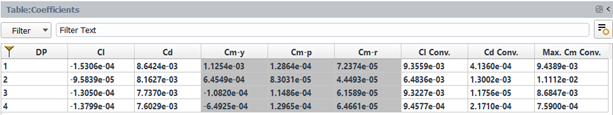

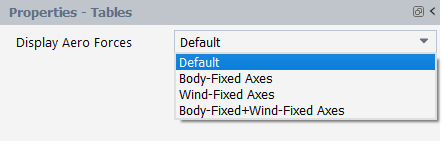

Table:Coefficients contains lift and drag coefficients calculated in wind-fixed coordinate systems, as well as yaw, pitching, and rolling moment coefficients calculated in body-fixed coordinate systems, which are highlighted in gray. Display Aero Forces in the Properties - Tables panel can also be changed to show forces and moments in the body-fixed, wind-fixed, or both coordinate systems at the same time. The convergence of the lift and drag coefficients is measured by the Cl Conv. and Cd Conv. columns. These are used to determine whether or not the convergence criteria have been met. The maximum value of the convergence of the yaw, pitching, and rolling moments is shown in the last column, Max. Cm Conv..

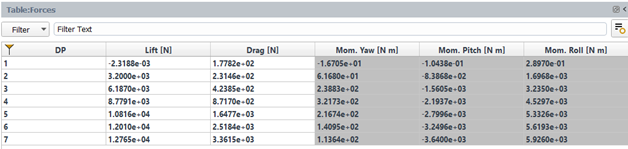

Table:Forces contains the lift, drag and moment forces. Coefficients, lift, and drag forces are computed in the wind-fixed coordinate system, while moment forces are computed in the body-fixed coordinate system.

Table:Residuals shows the final residuals as well as the number of iterations run for each design point.

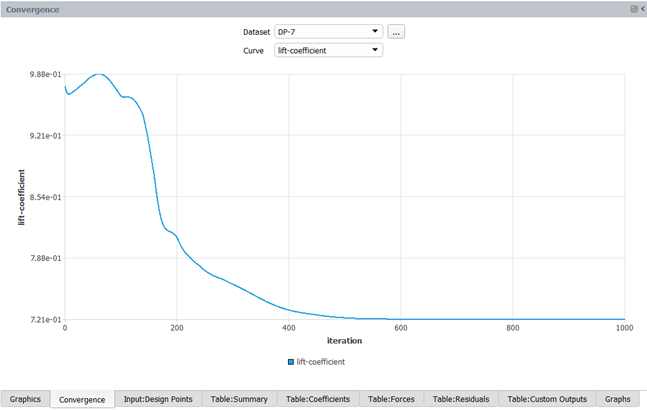

Based on the convergence status, you can continue to calculate selected design points from the current results. Although the convergence criteria have been partially met for design points 6 and 7, which have high angle of attacks, the average residual and the residual of aerodynamic coefficients are very low. The aerodynamic forces plateaued after 600 iterations, as shown in Figure 2.11: Convergence History of the Lift Coefficient for Design Point 7 and Figure 2.12: Convergence History of the Drag Coefficient for Design Point 7.

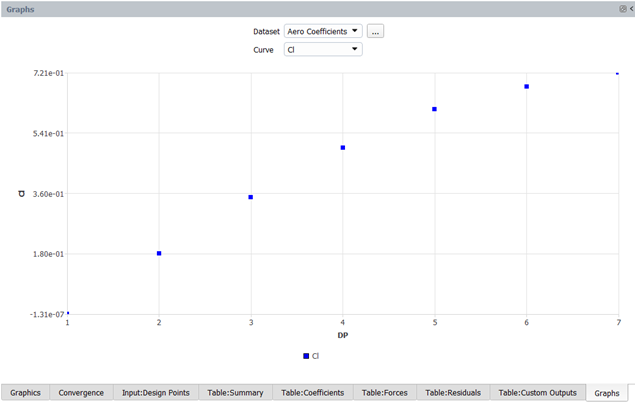

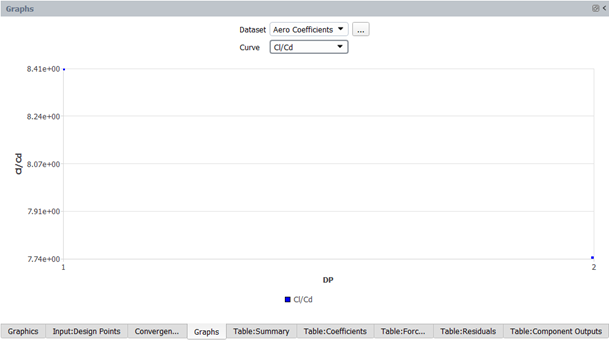

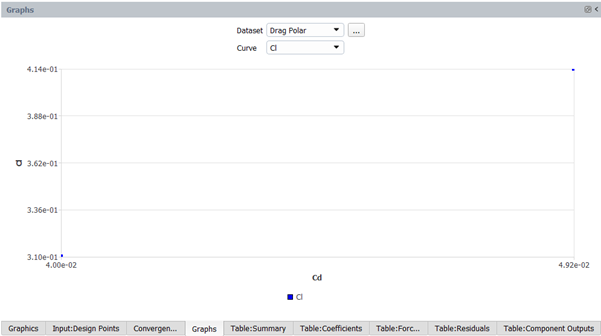

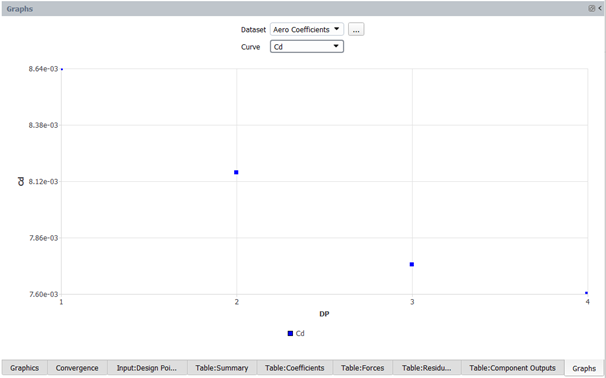

Click Graphs in the Outline View to show the plots of the aerodynamic coefficients defined in Fluent Aero. At the bottom of the Properties - Graphs window, click Plot Coefficients.

An X- Y plot of lift coefficient () vs. design point () will appear in the Graphics window. The drag and moment coefficients can be shown by selecting and from the Curve selection drop-down list.

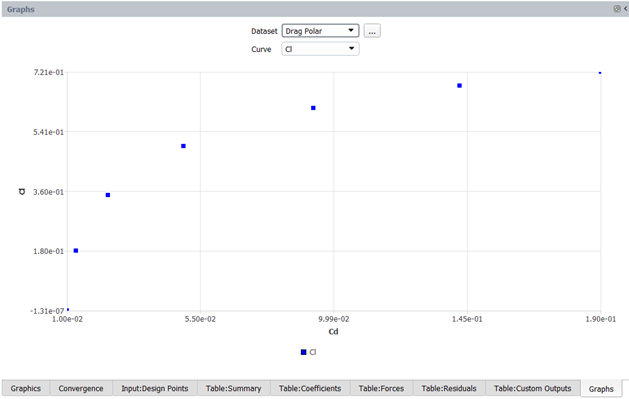

Click the button. An X-Y plot of Lift Coefficient (Cl) vs. Drag Coefficient (Cd) will appear in the Graphics window. Alternatively, you can simply change Dataset to from the Graphics window to show the drag polar plot.

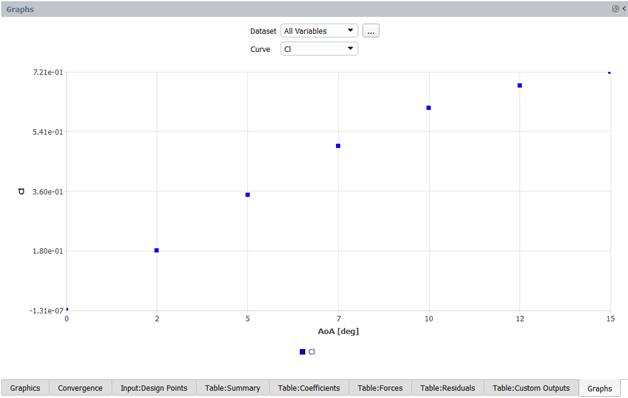

Click the button. An X-Y plot AoA vs. DP will appear in the Graphics window. Select from the Curve drop-down. There is an option button located on the right of the Dataset drop-down. This button can be used to modify some of the plot settings and export the plot to the disk. Click the option button and select → → to change the x variable to AoA. The plot of the lift coefficient vs the angle of attack will be shown.

In the Properties – Graphs window, you can load and plot a reference dataset to compare with the simulation results by using the function. To compare the Cl vs AoA curve from simulation with a reference data, set Dataset to and Curve to from the Graphs plot window. Ensure that AoA [deg] is the x-axis variable. Click . A file browser will appear. For this tutorial, you will use the results from a finer mesh to demonstrate this functionality. Browse to the reference_data folder inside the tutorial folder and select the ref-onera-wing-Cl-vs-AoA.csv file. The reference data will be loaded to the Cl curve.

Note: The reference file should contain row data separated by commas. The first line contains the x- and y- axis names of the plot that you want to compare to. The remaining lines contain the data values you would like to plot. The format of the file used here is shown in the image below:

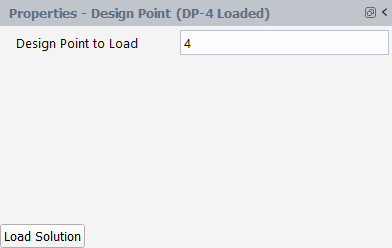

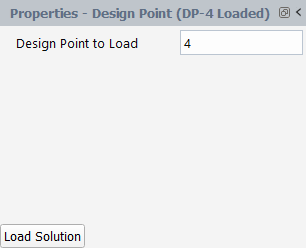

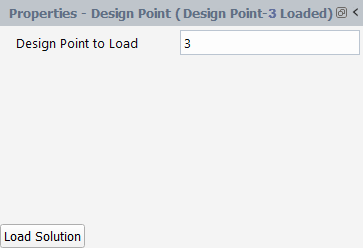

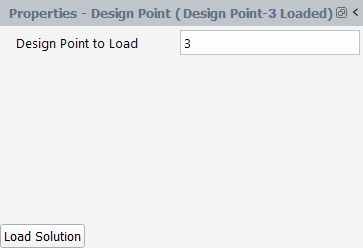

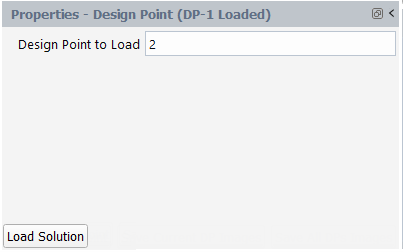

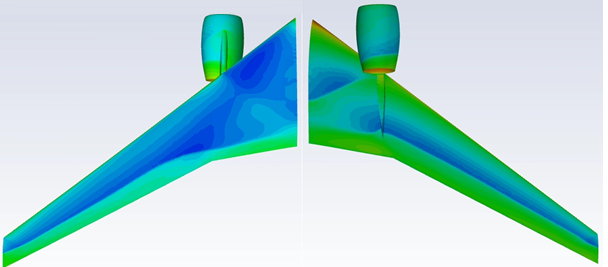

You will now go to the Design Point (DP-# Loaded) section. This section is used to visualize graphical results such as contours, vectors, pathlines, XY plots and scenes for a specific design point in the Graphics window. After creating these graphic objects, you can easily replicate them for the remaining design points with a single click. From the Properties – Design Point (DP-# Loaded) panel.

Set Design Point to Load to

4.Click to load the solution file of design point 4.

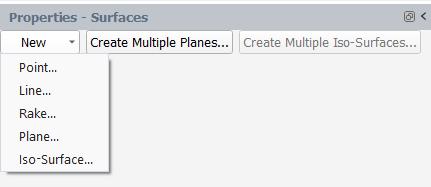

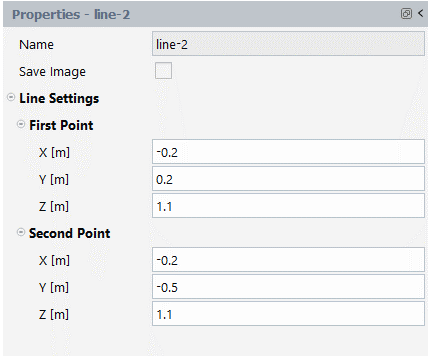

Go to the Surfaces node to create lines upstream of the wingtip, which will be used to generate pathlines in a later step.

Create a new line.

Results → Design Point → Surfaces → New → Line

A line type object line-1 appears under Surfaces.

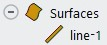

Set the following settings for line-1 in the Properties – line-1 panel.

In the First Point section:

Set X [m] to

-0.2.Set Y [m] to

0.2.Set Z [m] to

1.

In the Second Point section:

Set X [m] to

-0.2.Set Y [m] to

-0.5.Set Z [m] to

1.

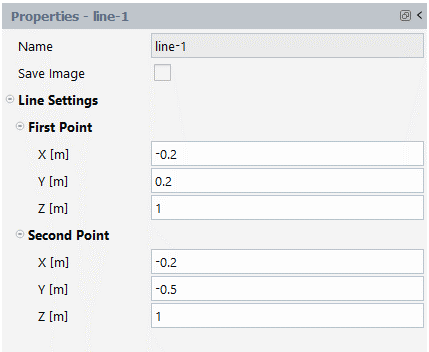

Create another new line. A line type object line-2 appears under Surfaces. To create line-2, follow the same steps as above, using the settings shown in the image below.

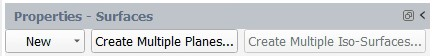

Create two wing crossing planes used to create contours.

Results → Design Point → Surfaces → Create Multiple Planes

In the Create Multiple Planes dialog box:

Set Name Format to

plane-z={z:+.2f}.Set Number of Planes to

2.Set Option to .

Set Normal Specification to .

Set Spacing [m] to

0.5.In the Point on First Plane section:

Set X [m] to

0.Set Y [m] to

0.Set Z [m] to

0.05.

When you're finished, click . Two planes now appear under Surfaces. The first plane is located near the wing root and the other closer to the mid span of the wing.

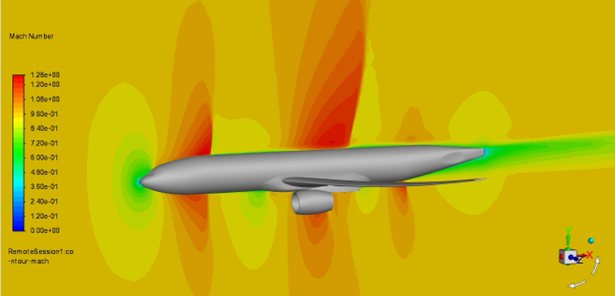

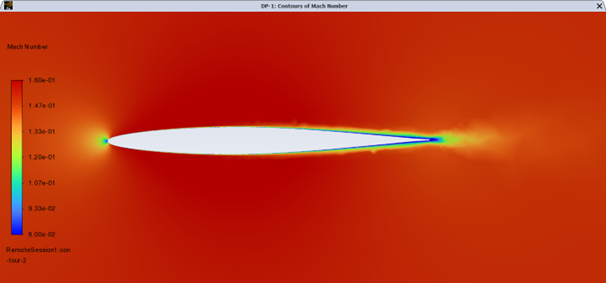

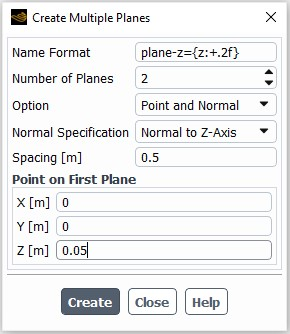

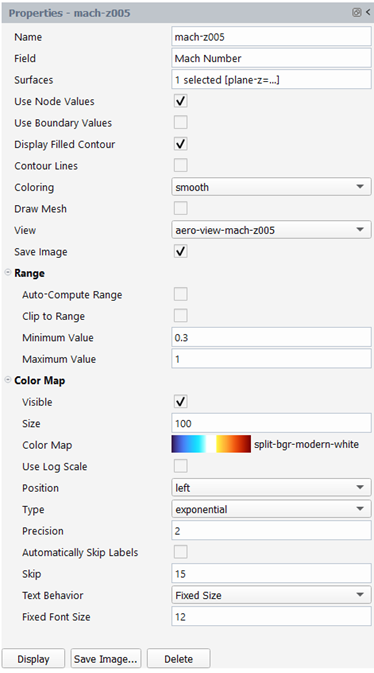

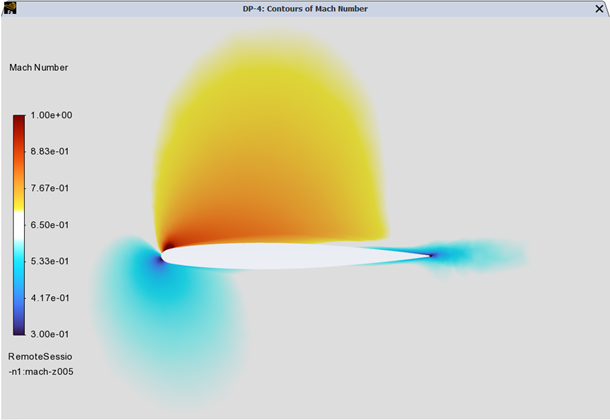

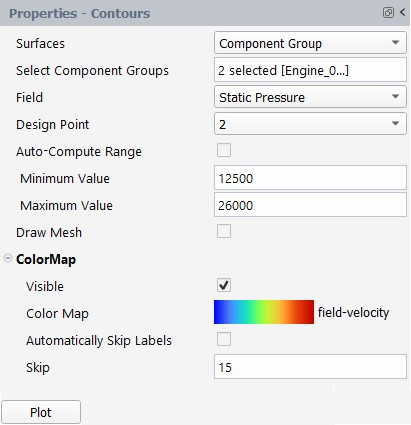

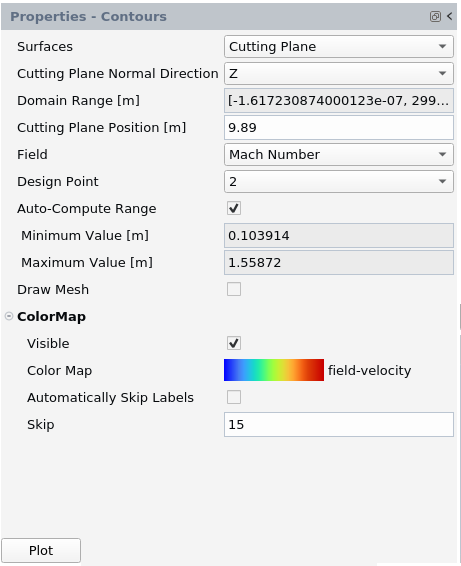

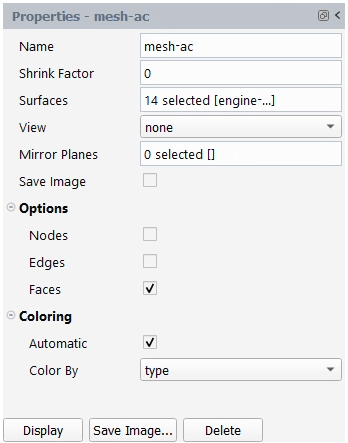

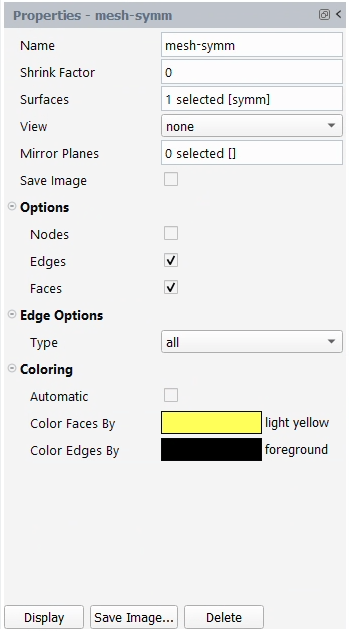

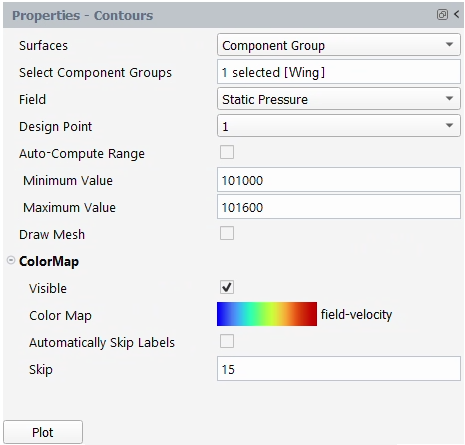

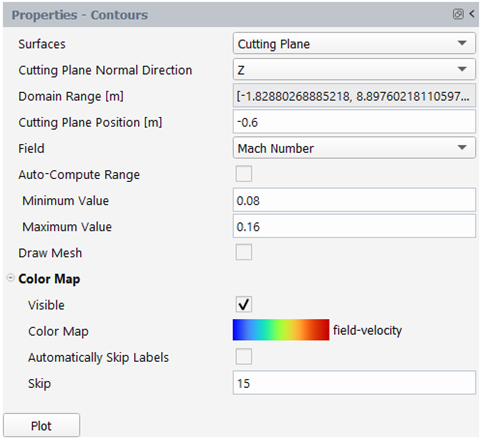

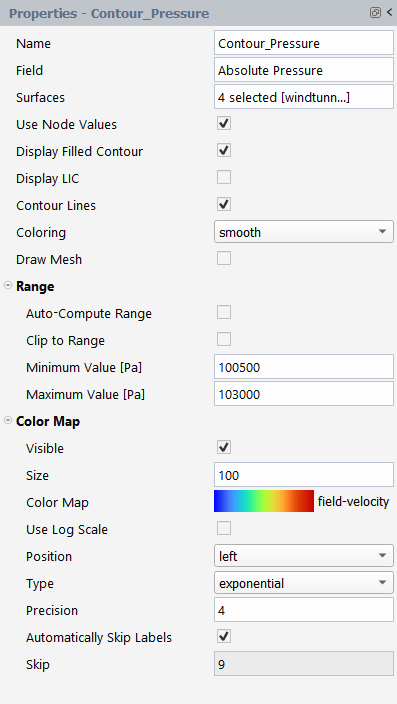

Select Contours under Graphics. There are two methods to creating contour. The first method is to right-click on Contours, select and specifying the contour properties. The second method is to predefine the properties from the Properties - Contours panel before creating the contour:

Results → Design Point → Graphics → Contours

Set Surfaces to Selected Surfaces.

Set Select Surfaces to .

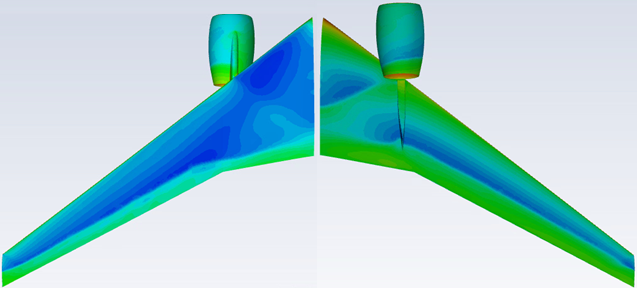

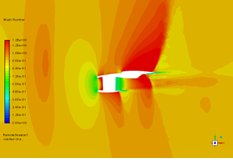

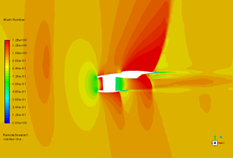

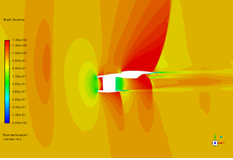

Set Field to Mach Number.

Disable .

Set Minimum Value and Maximum Value to 0.3 and 1 respectively.

In the Color Map section:

Enable .

Set Color Map to .

Disable .

Set Skip to

15.

Click to create and display the contour in the Graphics window. A contour-1 node now appears under Contours.

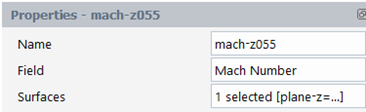

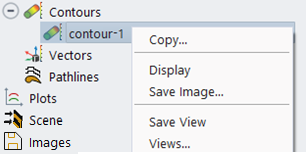

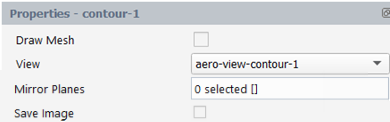

You will further adjust certain settings of contour-1. Select contour-1 under Contours and from the properties panel:

Change Name to

mach-z005.Enable the option to save the current contour image when executing the or command.

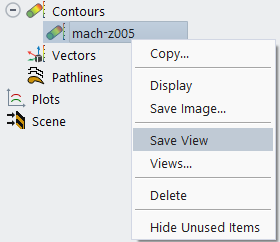

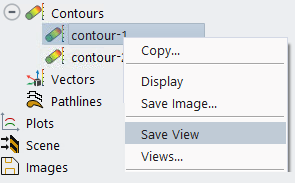

Go to the Graphics window and adjust the perspective view and position of the contour to your preference. From the Outline View, right click on mach-z005 and select the command. This will save the current view as aero-view-mach-z005 under the View option in the properties panel.

You can further adjust the remaining contour settings for mach-z005 in the properties panel. In the current example, keep the remaining default settings.

Click to update the contour in the Graphics window.

Note: The mesh used in this tutorial is very coarse. Its purpose is to quickly demonstrate a typical workflow in Fluent Aero and should not be relied upon for precise and/or accurate simulations. This mesh will not capture well viscous effects (such as viscous drag) or complex flow features (such as separation or wake).

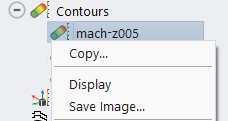

You will now use the command to create a contour of Mach number on plane-z=+0.55.

Right-click on contour mach-z005 and select .

From the properties panel of the new contour that appears:

Change Name to

mach-z055.Set Surfaces to .

Keep the remaining settings, including the View that you previously saved.

Click to show the contour in the Graphics window.

You will now create a contour of wall shear stress. Right-click on Contours and select . From the properties panel of the new contour:

Change Name to

wall-shear-stress.Set Field to under Wall Fluxes….

Select wing_bot, wing_te and wing_top for Surfaces.

Enable and .

Enable and .

Set Coloring to .

Disable .

Click to show the wall-shear-stress contour.

Adjust the view from the Graphics window. Right-click on wall-shear-stress and then select to save the view as

aero-view-wall-shear-stressunder View.

Enable the option to save the current contour image when executing the or command.

In the Range section:

Disable and .

Set Minimum Value and Maximum Value to

2.5and150respectively.

In the Color Map section:

Enable .

Set to

30.Set Color Map to .

Disable .

Set Skip to

5.For the remaining settings, keep the default options.

Click to update the contour in the Graphics window.

Create a vector plot.

Results → Design Point → Graphics → Vectors

New...

Set Name to

velocity-vector.Set Vector Field to .

Set Field to .

Set Surfaces to plane-z=+0.55.

Set View to .

In the Range section:

Disable and .

Set Minimum Value and Maximum Value to

0.3and1respectively.

In the Color Map section:

Disable .

Set Skip to

14.Set Fixed Font Size to

18.For the remaining settings, keep the default options.

Click .

Create a pathline object to show the flow near the wing tip.

Results → Design Point → Graphics → Pathlines

New...

Set Name to

pathlines-wing-tip.Set Color by to .

Set Release from Surfaces to line-1 and line-2.

Enable .

In the Range section:

Disable .

Set Minimum Value and Maximum Value to

0.3and1respectively.

In the Style section:

Set Style to .

Set Line Width to

3.

In the Accuracy Control section:

Enable .

Set Tolerance to

0.0001.

In the Color Map section:

Disable .

Change Color Map to .

Keep all other settings to their default values.

Click .

Note: The coarse mesh shows only limited details of the complex wingtip flow.

Adjust the view for your plot of pathlines around the wing tip from the Graphics window.

Right click on pathlines-wing-tip from the Outline View and select the command. The view will be saved as aero-view-pathlines-wing-tip under View.

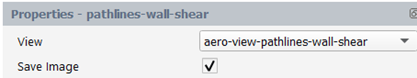

Create a pathline object to show the wall shear stress lines.

Results → Design Point → Graphics → Pathlines

New...

Set Name to

pathlines-wall-shear.Set Steps to

1500.Set Path Skip to

10.Under Options,

Enable .

Set On Zone to wing_bot, wing_te, and wing_top.

Set Color by to .

Set Release from Surfaces to wing_bot, wing_te, and wing_top.

In the Range section:

Disable .

Set Minimum Value and Maximum Value to

2.5and150respectively.

In the Style section:

Set Style to .

Set Line Width to

3.

In the Color Map section:

Set Position to .

Keep all other settings to their default values.

Click Display.

Adjust the view for your plot of pathlines on the wing surfaces from the Graphics window.

Right click on pathlines-wall-shear from the Outline View and select the command. The view will be saved as aero-view-pathlines-wall-shear under View.

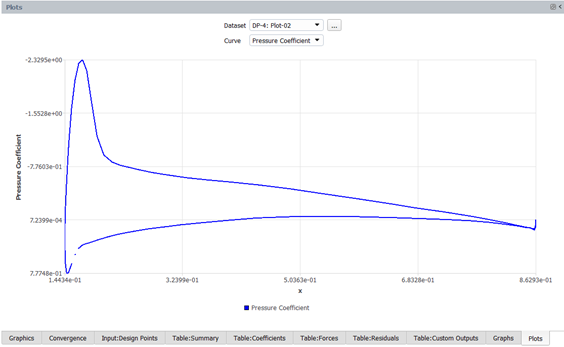

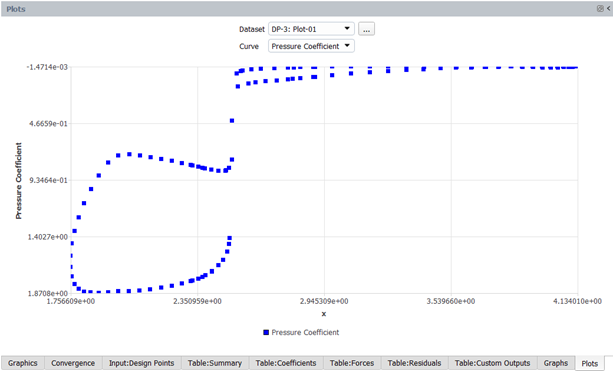

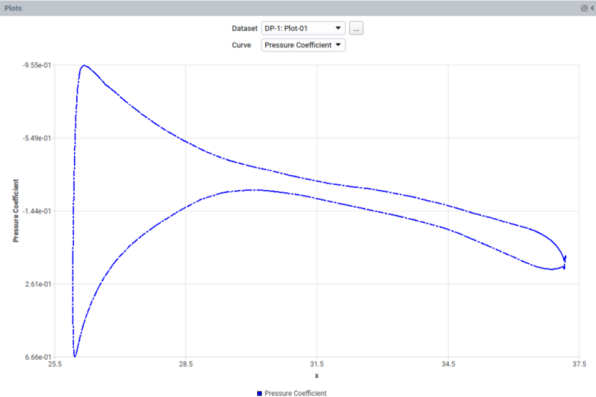

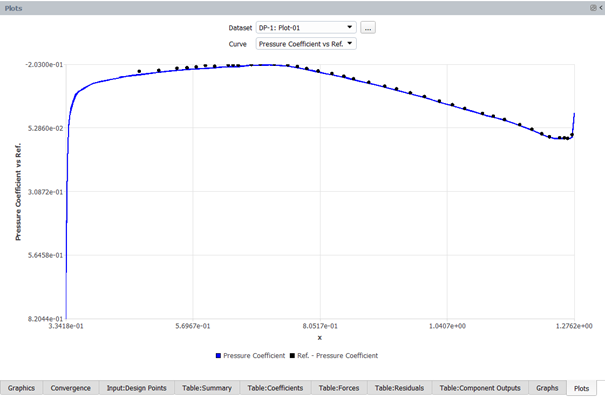

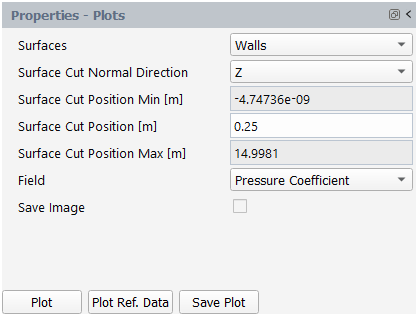

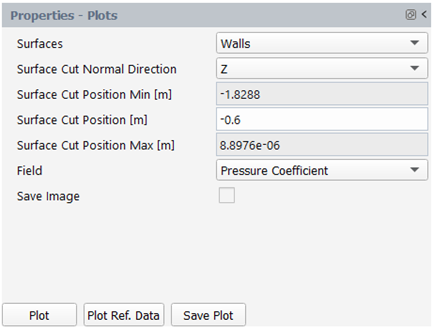

Click Design Point (DP-4 Loaded) → Plots in the Outline View. The Plots options can be used to quickly display simple 2D plots of selected design points and solution variables. The Properties - Plots window will be displayed.

Set Surfaces to .

Set Surface Cut Normal Direction to .

Set Surface Cut Position [m] to

0.25.Set Field to .

Click .

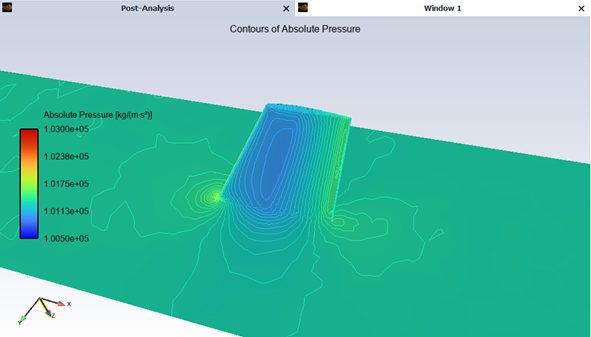

The pressure coefficient on the walls of DP-4 at Z=0.25m will be plotted in the Plots window.

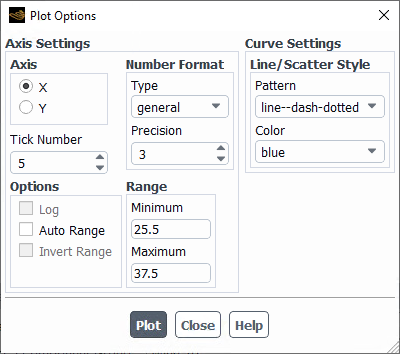

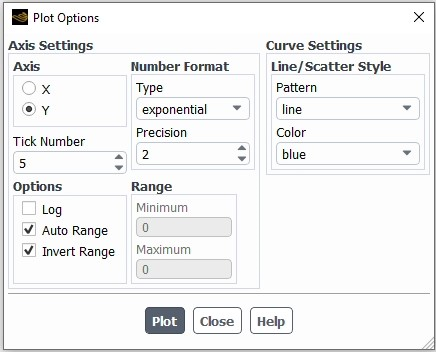

A Plot Options panel will appear after clicking the button. You can use this panel to customize plot settings for both axes. Press to apply these settings.

A .csv file will be saved in the Results folder after clicking the button, which is visible within the DP-4/Data folder in the Project View.

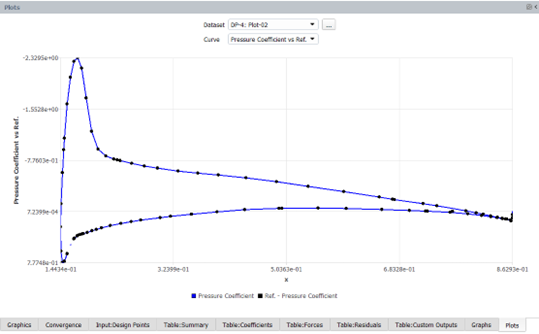

Click the button to load and plot a reference dataset in the current plot. In the dialog window that appears, browse to the reference file ref-onera-wing-Cp-7.5deg-section-0.25m.csv in the reference_data folder, and click . You can use the button to export the current plot to a .png file on disk. The reference data will be imported in the DP-4/Data folder in the Project View.

Figure 2.22: Data Folder in the Project View After Creating a Cut Plot and Plotting Reference Results

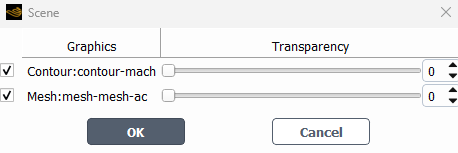

Create a scene object.

Results → Design Point → Scene

New...

Open the Scene dialog box by clicking within the Graphics Objects field:

Enable , , and .

Set Transparency of to

50.Click to close the window.

Click , adjust the colormap positions and the view of your figure.

Right click scene-1 from the Outline View and select the command. The view will be saved as under .

After generating all the graphics objects for design point 4, you can load a different design point and reuse the same graphics objects. You also have the option to save images of the graphics objects created for the current design point or for all updated design points.

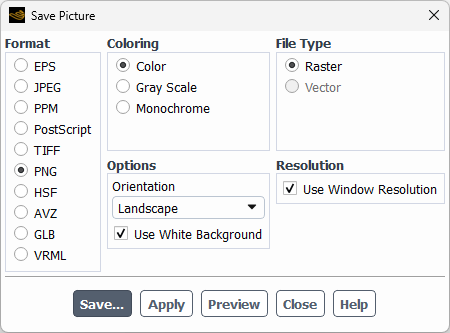

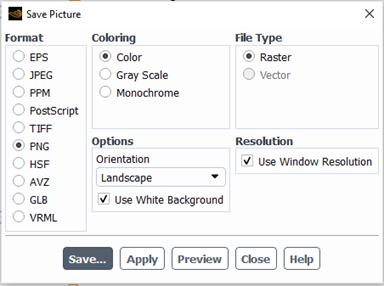

To save an image, navigate to the properties panel of the desired graphics objects and enable the option. For example, select for pathlines-wall-shear and other results you wish to save.

You can also click the button in the properties panel of a graphics object to customize the image-saving settings. Click to save these settings.

To save all graphics objects with the Save Image flag enabled for DP-4, click from the Properties – Design Point (DP-4 Loaded) panel. Fluent Aero will iterate over all the graphics objects with the Save Image flag activated and save the images in the Results folder.

To display the graphics objects for a different design point, change Design Point To Load to the desired design point and click . You can also load the results from the Project View by right-clicking on the solution file of the design point of interest and then selecting .

If you want to save images that have the option enabled for all the updated design points, click . The settings from the properties panel, including the specified view and save image options will be applied.

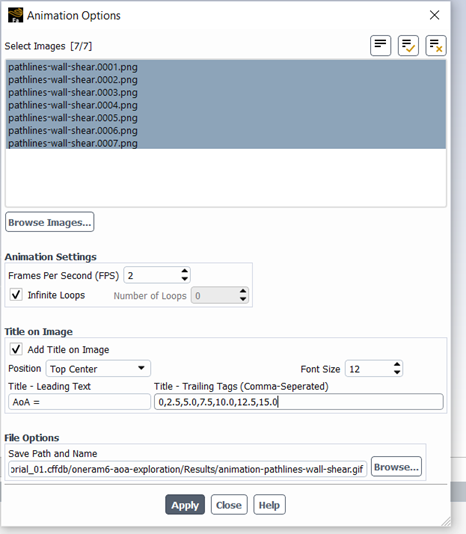

You will now create an animation using the images of pathlines-wall-shear saved in the previous step.

Click the button located in the Results → Animation section of the ribbon.

In the Animation Options dialog box that appears, do the following:

Navigate to the Results folder of the current simulation and select all the pathlines-wall-shear*.png files. The order in which you select the images determines the order in which they appear in the animation.

In the Animation Settings section:

Set Frames Per Second (FPS) to

2.Enable .

In the Title on Image section:

Enable .

Set Position to .

Set Font Size to

12.Set Title - Leading Text to

AoA =.Set Title – Trailing Tags (Comma-Separated) to

0,2.5,5.0,7.5,10.0,12.5,15.0.

Under File Options, specify the Save Path and Name for your animation.

Click to create and save the animation.

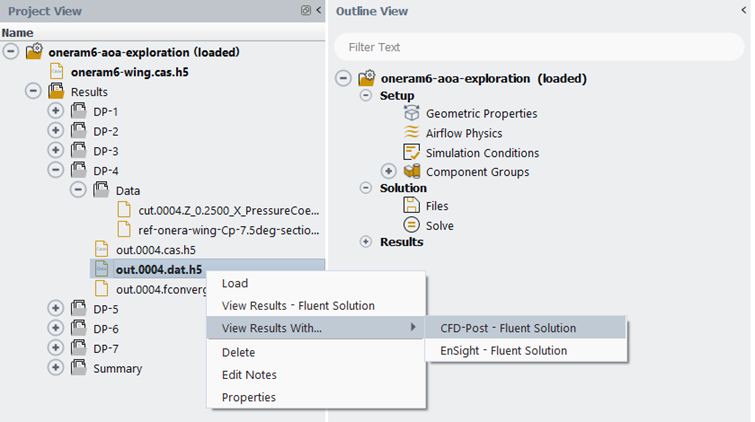

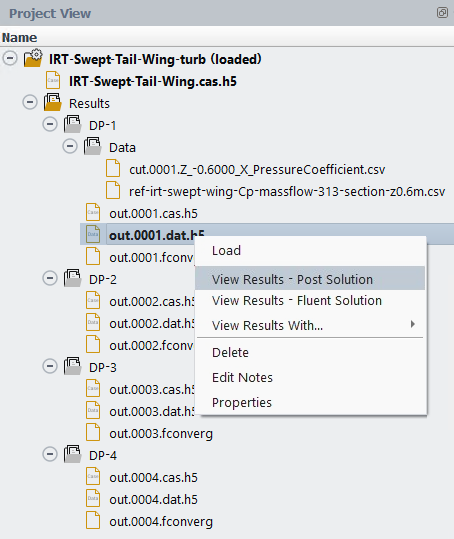

It is also possible to post-process Fluent Aero simulation results using an external post processing tool such as CFD-Post™ and EnSight™. By right-clicking a .dat.h5 file in the Project View, a menu appears with several post-processing options such as and .

In this tutorial, you will use CFD-Post. Right-click out.0002.dat.h5 and select → to view the result file in CFD-Post. A CFD-Post window will appear where the data file can be further post-processed.

.

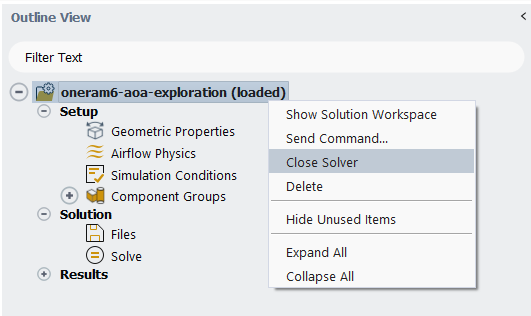

After completing the post-processing of the current simulation, right-click oneram6_aoa_exploration from the Outline View and then select . An information panel will appear to ask you if you want to save the case file or not. Click to save the case file.

If you would like to create a new simulation, select Simulation → from the Project ribbon. Browse and select a file to create a new simulation.

Once you have completed all your simulations, close the project and exit Fluent Aero by selecting Project → followed by File → .

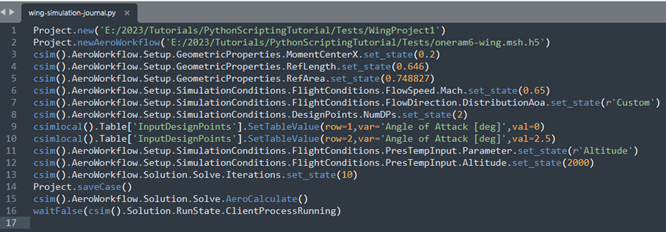

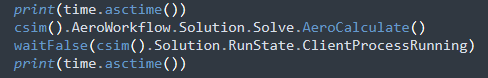

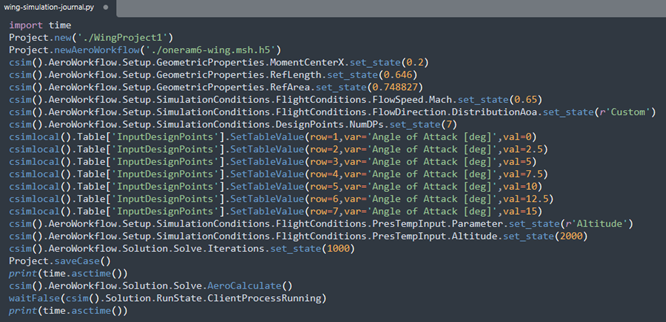

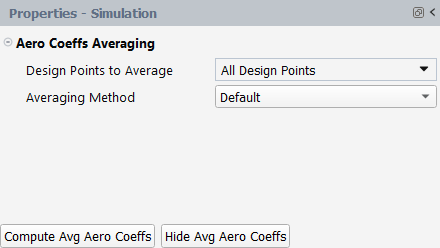

The objective of this part of the tutorial is to demonstrate the use of python journal scripting in Fluent Aero to complete the calculation of the design points. Specifically, this tutorial will demonstrate the following steps:

Recoding a python journal while setting up a simulation

Manually editing he python journal, including:

Adding additional Fluent Aero python commands

Adding external python modules commands

Executing the python journal (including using Fluent Aero in batch mode on a cluster)

Archiving the completed Fluent Aero project and deleting files to preserve disk space

In the following steps, we will record a python journal while setting up a base simulation using the Fluent Aero graphical user interface.

For this tutorial, we will again use the oneram6-wing.msh.h5 file from the fluent_aero_tutorial.zip, from Part 1 of this tutorial, or – here .

Extract the oneram6-wing.msh.h5 file for this tutorial.

Launch Fluent 2025 R2 on your computer. On the Fluent Launcher panel, set the Capacity Level to . Then select Aero. Set the number of Solver Processes to

4-8. Click .Select → In the Select File dialog, set the name for the journal file as

wing-simulation-journal.py. Click .Any operation that you perform in Fluent Aero will now be recorded to this python journal file.

In the Project ribbon panel, select Project→ and enter

WingProject1to create a new project folder.Once again, in the Project ribbon, select Simulation→, and browse to and select the oneram6-wing.msh.h5 file. A New Simulation window will appear. Enter the Name of the New Simulation as

oneram6-wing, and check . Click .

In the Outline View, click Geometric Properties.

Define the orientation of the geometry within the computational domain, which will be used to compute the aerodynamic forces.

Set Moment Center: X Position [m], Moment Center: Y Position [m] and Moment Center: Z Position [m] to

0.2,0, and0, respectively.Set the Reference Length [m] to

0.646, which corresponds to the mean chord length.Set the Reference Area [m^2] to

0.748827.

In the Setup tree, go to Airflow Physics. A Properties – Airflow Physics window appears below the Outline View.

In the Models section:

Set Knudsen Number Criterion to .

In the Setup tree, go to Simulation Conditions. In the Properties – Simulation Conditions window, go to Flight Conditions.

In the Design Points section:

Set the Number of Design Points to

2.

In the Flow Speed section:

Set the Mach Number to

0.65.

In the Flow Direction section:

Set Parameter to .

Set Distribution: Angle of Attack to .

In the Pressure and Temperature section:

Set Parameter to .

Set the Altitude [m] to

2000.

An Input:Design Points table will be created in the Graphics window on the right-hand side of the user interface.

In the Angle of Attack [deg] column, set the angle of attack for DP 1 and 2 to

0and2.5, respectively.

Under Solve, keep the default number of Iterations of 100. Keep both Convergence Settings and Convergence Criteria as .

Click .

The calculation will begin. DP-1 and DP-2 will be calculated sequentially for 100 iterations.

From the dropdown menu, select → to stop recording the python journal.

In the following steps, we will use a tex editor to manually edit the python journal by adding additional Fluent Aero python commands and by including the use of an external python module.

Open the wing-simulation-journal.py file in a text editor to view its contents.

Note: All operations performed in the previous steps are recorded in this journal.

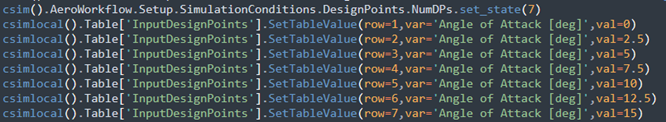

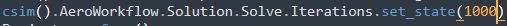

Modify this journal with additional settings by following the steps below:

Change the file paths associated with

Project.newandProject.newAeroWorkflowso that they are relative paths. This will allow you to use these paths on other computers that don’t have a similar directory structure.

Increase the number of design points to seven (

NumDPs.set_state() and define the7)Angle of Attack [deg]of each design point as shown below.

Increase the number of iterations to

1000, so sufficient iterations are performed for each design point.

Within the python script, it is also possible to import and use other python libraries. As an example, modify the script to add time printouts before and after the simulation, as follows:

At the top of the file, import the time library

Before and after the

AeroCalculatestep (equivalent to clicking the button in Fluent Aero), use thetimelibrary to print the current time to the transcript.

You can expand your usage of python modules to do any number of python operations during the execution of your script, including file management, post processing, and more.

Note: The time module is only used as an example.

After the above modifications, your script should appear as follows:

In the following steps, you will copy your input mesh file and Python journal file to a compute machine. These files will be used to launch Fluent Aero in batch mode and execute the required Python journal operations.

Create a directory on your compute machine or cluster called

PythonScriptingTutorial. Copy the oneram6-wing.msh.h5 and wing-simulation-journal.py files to this directory on a compute cluster where you would like to run your full simulation.Open a terminal and navigate to the PythonScriptingTutorial directory that contains your files.

Launch Fluent Aero using the aero executable in batch mode and read your python journal script using the following command:

/path/to/ansys_inc/v252/fluent/bin/aero -R wing-simulation-journal.py -Nwhere -R specifies the journal to be read, and -N specifies to run in batch mode.

[Optional - If using a compute cluster with a queuing system, you must include the proper job scheduler arguments required by your machine. One way to do this is to include the scheduler arguments in the launch command. In the example below, a slurm cluster is being used, and the command line has been extended using the scheduler arguments.]

/path/to/ansys_inc/v252/fluent/bin/aero -R wing-simulation-journal.py -N -t28 -scheduler=slurm -scheduler_queue=partition-name -scheduler_account=account-name -scheduler_headnode=visualization-node-nameNote: In some instances, a cluster may require additional commands or a different approach to launch Fluent Aero. More information on these different approaches can be found in Launching Fluent Aero in Batch or on a Cluster using Job Scheduler.

Fluent Aero will launch in batch mode, read wing-simulation-journal.py and execute the contents of the script. The Console log of actions performed by Fluent Aero should appear in the terminal. Once the python script has been fully executed, the Fluent Aero batch process will close.

Note: While the simulation is running in batch mode, do not open the project using the Fluent Aero user interface. If you would like to view the results in the user interface, wait until the batch run has completed.

In the following steps, you will reduce the disk space used by the project by deleting unnecessary files, and subsequently archive the project using the .tar format.

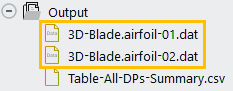

After successful execution of the python script, two files will have been produced in the PythonScriptingTutorial directory:

A WingProject1.flprj project file, which is an XML format file that contains information about all files associated with the project (location, dependencies, metadata)

A WingProject1.cffdb folder, which contains all the files associated with the project.

Creating an archive of the complete project:If there are no disk space limitations, you can archive the complete project by creating a single .tar file of these two items, using the following command:

tar -czvf WingProject1-Complete.tar.gz WingProject1.flprj WingProject1.cffdbThis creates an archive of the project with a size of about 400Mb.

Deleting unnecessary case and solution files before archiving the project, to preserve disk space:If there are disk space limitations, you can delete some case and solution files before archiving the project.

Some files should never be deleted, as they are essential for maintaining the integrity of the Fluent Aero project. Without these files, the Fluent Aero project and simulation will not load correctly. These files include:

The top level case file of a simulation. In this case, oneram6-wing/oneram6.cas.h5.

The run settings of a simulation. In this case, oneram6-wing/Results/run.settings.

However, some files are not required for Fluent Aero to load correctly, and can be deleted to save space. These include:

The design point case files, in this case, oneram6-wing/Results/out.000#.cas.h5. These files are only used to allow you to repeat the design point calculation inside a classic Fluent Solution environment – they are not required by Fluent Aero. You can safely remove these files to preserve space without affecting the integrity of your Fluent Aero project.

The design point solution files, such as oneram6-wing/Results/out.000#.dat.h5, contain the complete CFD solution for the design point. These files are essential for detailed investigation and post-processing, including creating contours and images.

If you intend to perform detailed post-processing and generate contour images, you must retain these files. However, if you only need the automatically tabulated post-processed results (such as lift and drag coefficients) provided by the Table-*.csv files and the WingProject1.flrpj file, you may choose to delete these solution files to save space in your archive.

Since the default file settings were used, the completed simulation Results folder (WingProject1.cffdb/oneram6-wing/Results) contains design point case and solution files for each of the seven design points (out.000#.cas.h5 and out.000#.dat.h5).

While this is entirely dependent on the specific requirements of the project, a good intermediate approach would be to keep the case and solution files for a single design point (to allow detailed post processing of at least one design point condition), and to remove the case and data files for all other design points (to preserve space in your archive).

Additionally, you have a few options for removing these files. You can either completely delete the files from the folder and then create an archive (using the previous

tarcommand), or you can exclude these files from the archive from within thetarcommand.To exclude all design point case and data files except for design point 1 from the archive, use the following command:

tar -czvf WingProject1-Reduced.tar.gz –exclude=’out.000[!1]*.*.h5’ WingProject1.flprj WingProject1.cffdbNotice that this creates an archive of the project with a size of about 75Mb (which is about 20% of the size of the archive of the complete project).

Note:

Note: There are various methods for performing this cleanup, including manual deletion, scripted deletion, and using tools like tar or zip to create the archive. The key takeaway from this section is that, depending on user requirements, design point case and solution files can be optionally removed without compromising the integrity of the project.

Now that you have a neatly packaged archive of the project, you can upload this file to any computer, and unpackage it at a later time to do additional calculations or post processing.

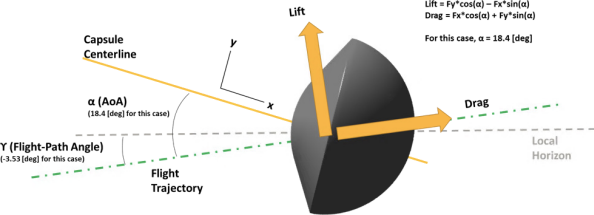

The main objective of this tutorial is to use Fluent Aero to compute the flow around an Earth re-entry capsule in a range of hypersonic flight conditions. The flight conditions used in this tutorial correspond to conditions experienced at different altitudes during an example flight path of a reference re-entry capsule, at altitudes ranging from approximately 50-70 [km] (Part I – Earth Re-Entry Simulation) and 80-92 [km] (Part II – Earth Re-Entry Simulation at High Altitudes). To improve accuracy, mixture representations of air are used in these simulations.

This tutorial also includes a demonstration case (Part III – Modeling the Flow Around an Entry Capsule in Martian Atmosphere) of a capsule entering the Mars atmosphere while considering air mixture properties and altitude conditions of the Martian atmosphere.

Note: Additional feature license is required to enable the use of this model. Contact your Ansys representative to check for the availability of the license increment.

Part I – Earth Re-Entry Simulation

Download the fluent_aero_tutorial.zip file here .

Unzip fluent_aero_tutorial.zip to your working directory.

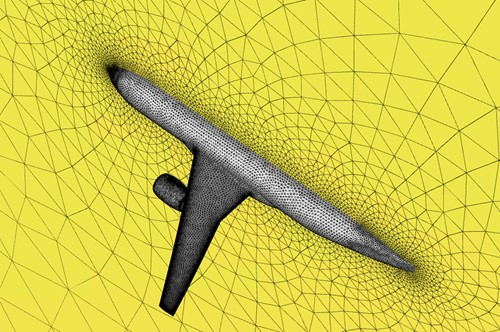

Extract the Capsule.msh.h5 file for this tutorial. The grid is an all-poly mesh which consists of 620,000 nodes and 180,000 cells. The limits of the computational domain are defined by a pressure-far-field, pressure-outlet, and a symmetry plane in the Z direction.

Launch Fluent 2025 R2 on your computer. On the Fluent Launcher panel that appears, set the Capacity Level to . Then select Aero. Set the number of Solver Processes to

4-16. Click .In the Fluent Aero workspace, go to the Project ribbon. Click Workspaces → , and make sure to uncheck , and .

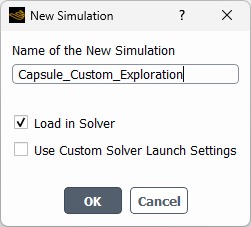

When Fluent Aero first opens, the Project tab will be displayed by default. In the Project ribbon panel, select Project → and enter

Fluent_Aero_Tutorial_02to create a new project folder.In the Project’ ribbon, select Simulations → , and browse to and select the Capsule.msh.h5 file. A New Simulation window will appear. Enter the Name of the New Simulation as

Capsule_Custom_Exploration, and check .

The case file will open and a background solver session will load. A new simulation folder will be created in your project folder. Fluent Aero will convert the .msh.h5 grid file to a .cas.h5 format case file and the latter will be imported in the simulation folder as Capsule.cas.h5.

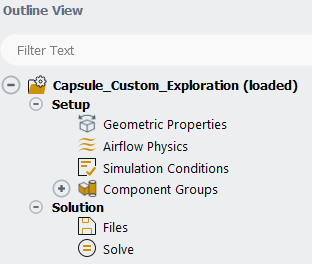

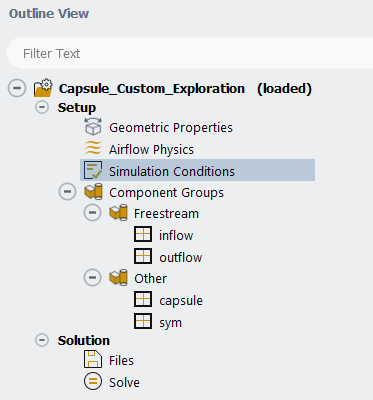

After the .cas.h5 file has been successfully loaded, a new Outline View tree appears under Capsule_Custom_Exploration (loaded).

While importing, Fluent Aero will search for and find the pressure-far-field zone that defines the external boundary of the domain. Its presence will cause Fluent Aero to determine that this case is using a Freestream Domain Type, and the following message will be reported in the Console.

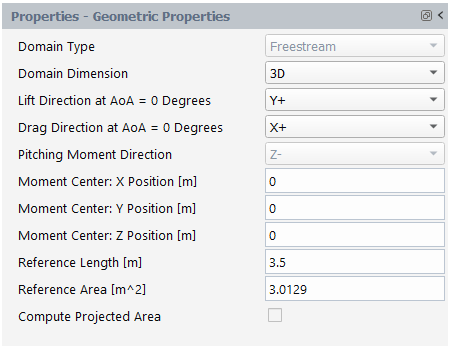

From the Outline View window, go to Geometric Properties. At the top of the Properties – Geometric Properties window, notice that the Domain Type has been automatically set to .

Define the orientation of the geometry within the computational domain. This is used to compute the aerodynamic forces.

Set Domain Dimension to .

Set Lift Direction at AoA = 0 degree to .

Set Drag Direction at AoA = 0 degree to .

The Pitching Moment Direction will be automatically set to .

Set the Moment Center X-, Y- and Z-Position [m] to

0,0, and0, respectively.Set the Reference Length [m] to

3.5.Set the Reference Area [m^2] to

3.0129.

In the Setup tree, go to Airflow Physics. A Properties – Airflow Physics window appears below the Outline View window.

In the Solver section:

Set Type to .

In the Models section:

Set Viscous to . When selected, a Transition and Fully Turbulent section appear below allowing you to define the Reynolds Number Threshold and Viscous Model to apply for each flow regime.

Set Reactions to . When enabled, you will be able to use a mixture representation of air in the next step and the Two Temperature model will be automatically set to .

Note: Additional feature license is required to enable the use of this model. Contact your Ansys representative to check for the availability of the license increment.

Set the Knudsen Number Criterion to .

In the Transition section:

Set the Reynolds Number Threshold that separates laminar and transition flows to

3e+05.Set the Viscous Model for design points within the transition flow regime to .

In the Fully Turbulent section:

Set the Reynolds Number Threshold that separates transition and fully turbulent flows to

5e+05.Set the Viscous Model for design points within the fully turbulent flow regime to

K-Omega SST.

In the Materials section:

Set the Air Properties to .

Set the Mass Fractions by clicking the button located on the right-hand side of the mass fractions display box to the species fractions shown below.

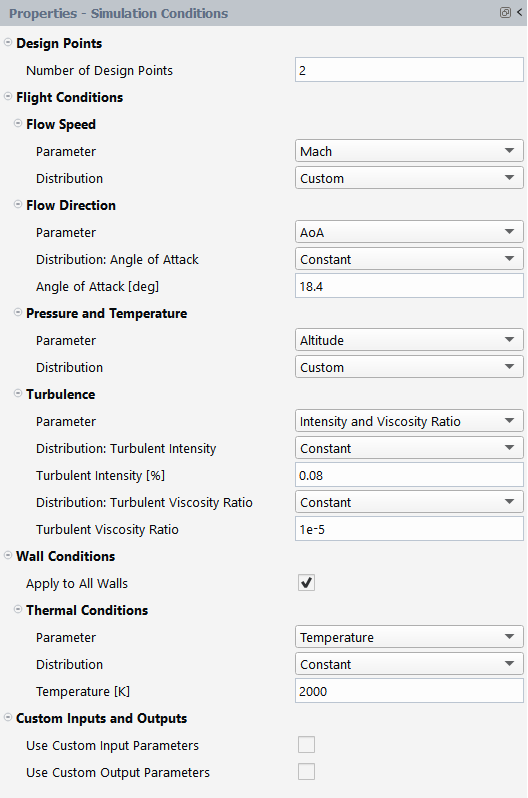

In the Setup tree, select Simulation Conditions. In the Properties – Simulation Conditions window.

Set the Number of Design Points to

3.In the Flow Speed section:

Set Parameter to .

Set Distribution to .

For Flow Direction,

Set Parameter to .

Set Distribution: Angle of Attack to .

Set Angle of Attack [degrees] to

18.4.

In the Pressure and Temperature section:

Set Parameter to .

Set Distribution to .

In the Turbulence section:

Set Parameter to .

Set Distribution: Intermittency, Distribution: Turbulent Intensity and Distribution: Turbulent Viscosity Ratio to .

Set Intermittency to

1..Set Turbulent Intensity [%] to

0.08.Set Turbulent Viscosity Ratio to

1e-5.

In the Wall Conditions section:

Enable .

In the Thermal Conditions section:

Set Parameter to .

Set Distribution to .

Set Temperature [K] to

2000.

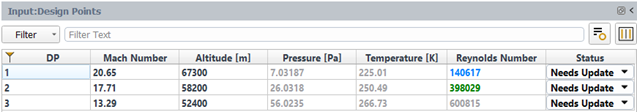

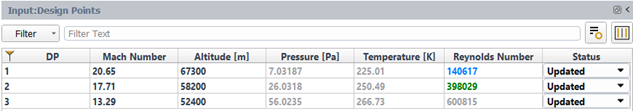

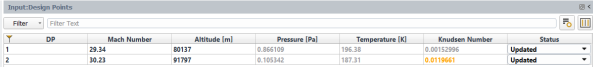

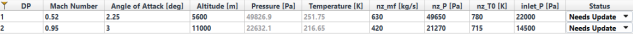

An empty Input:Design Points table will be created with 3 rows, one for each design point. You can manually fill the Input:Design Points table by clicking each entry cell and entering a value. Notice that there are 7 columns in the table. The first column specifies the Design Point number, and cannot be edited. The second and third columns are for specifying the variable inputs of Mach Number and Altitude [m], respectively. Since was selected under Pressure and Temperature, Pressure [Pa] and Temperature [K] are also shown in the table. These columns cannot be edited, as they will be automatically calculated and filled based on the Altitude input, which uses the International Standard Atmosphere. Since the Viscous Model is set to , the next column shows the Reynolds Number. The final column lists the Status of each design point calculation.

Begin to manually fill the table by clicking the Mach Number cell of design point 1, and enter

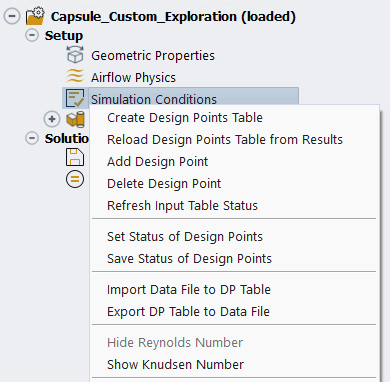

20.65. Next, click the Altitude [m] cell and enter67300. Notice that the Pressure [Pa], Temperature [K] and Reynolds Number cells are automatically filled with 7.0319, 225.01 and 140617, respectively. The Reynolds number value is highlighted in blue, indicating that the flow is in the laminar regime.Fill the remainder of the table by importing the data from a .csv file. Right-click the Simulation Conditions and select from the drop-down list of commands.

Navigate to and load the Capsule_Input_3_Design_Points.csv from the fluent_aero_tutorial folder and the remainder of the Input:Design Points table will be filled.

You will notice that the Reynolds number values for the second and third design points are displayed in green and gray color, indicating that they are in the transition and fully turbulent flow regimes respectively.

Note: The Status of each design point (DP) is currently set to , because they have not yet been calculated.

From the Properties - Simulation Conditions window, enable .

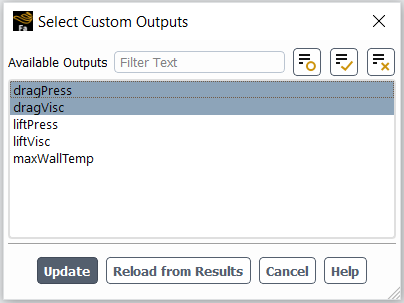

A selection panel will appear which contains a list of pre-defined custom-output variables. Select dragPress (pressure induced drag force), and dragVisc (wall shear stress induced drag force) and click . Fluent Aero will create the selected variables in the solver and the results of these output parameters will be shown in a table at the end of the calculation. Refer to Fluent Aero for more details about the functionality of the custom input/output parameters.

Go to Component Groups. Two default Component Groups have been created after the simulation is loaded. The Freestream group contains a pressure-far-field and a pressure-outlet zone that define the external boundary of the domain, and is where the freestream atmospheric flight conditions for each design point are defined as boundary conditions. The Other group contains the remainder of the boundary zones which are the walls of re-entry capsule and a symmetry plane of the simulation domain.

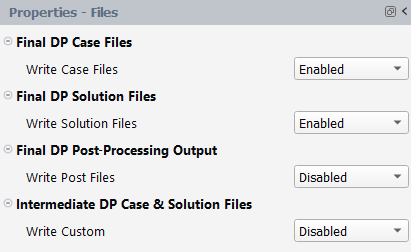

In the Outline View, go to Solution → Files. This step allows you to control the output files written per design point. Keep the default options.

Under Solve, set the number of Iterations to

1500. Keep both Convergence Settings and Convergence Criteria as .Click the button at the bottom of the Properties - Solve panel. The simulation will first initialize using the flight conditions of DP-1 and then DP-1 will begin to iterate. The residuals plot of DP-1 will appear in the Convergence window located on the right of the screen.

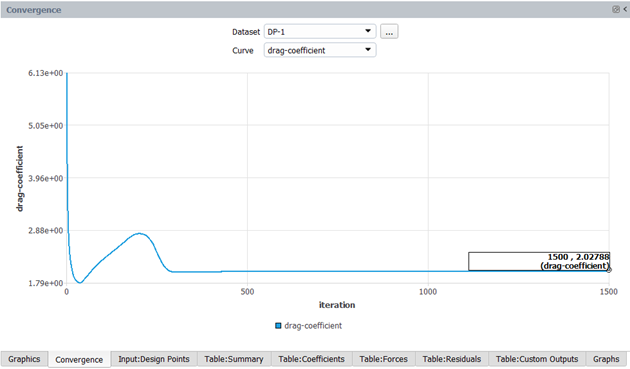

In the Convergence window, set Dataset to and Curve to . The evolution of the drag coefficient for DP-1 will be displayed. You can query the value of the drag coefficient by left-clicking the curve.

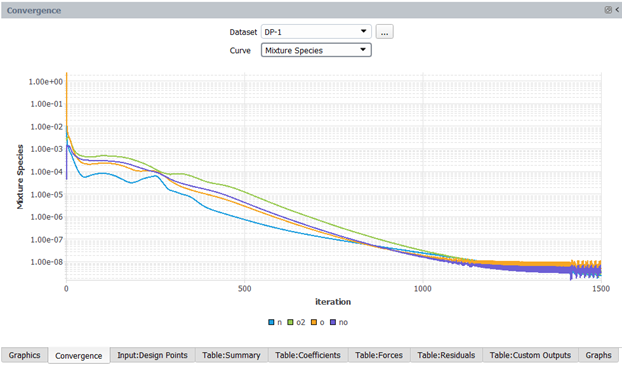

In the Convergence window, set Dataset to and Curve to . The residuals of species mass fractions for will be displayed. You can query the value of a specific species by left-clicking the curve.

After 1500 iterations, the DP-1 calculation is complete, the Status column in row 1 of the Input:Design Points table is set to , the results data file (.dat[.h5]) is saved, and the DP-2 calculation begins.

After all the design points have been updated, the status of the Input:Design Points table will be set to for all the design points.

A Results node will be displayed in the Outline View after the simulation starts. This allows you to quickly postprocess all design point solutions, by obtaining aerodynamic coefficient plots, creating contour plots of solution fields, comparing solution fields to experimental data, and more.

Go to the Simulation node which provides a comprehensive view of aerodynamic coefficients across all design points. The first element in the Simulation node is Tables. In the current tutorial, five different Tables will be automatically created in the Graphics window area once the calculation is completed.

Note: You can also click Tables → button and the results tables will be exported to the Results folder of the current simulation and they will be visible in the Project View under the Summary folder.

Click the Table:Summary, Table:Coefficients, Table:Forces, Table:Residuals, and Table:Custom Outputs tabs at the bottom of the Graphics window to reveal each table.

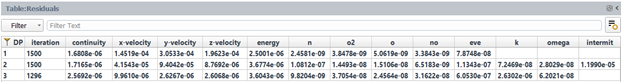

Table:Summary summarizes the flight conditions and convergence information for each design point.

Note: You can see from the convergence curves that lift and drag plateaued. However, you may notice in the final column of this table that all 3 design points have not fully met the default residuals convergence criteria of 1e-5. To have the Conv. Criteria Met? column set to , you could relax the convergence criteria by increasing the values of Residuals Convergence Cutoff or calculate for more iterations until the default convergence criteria is met. You can go to Solve, change Convergence Criteria to and Residuals Convergence Cutoff will be available within the Properties – Solve panel.

When the option is selected from the Display Aero Forces dropdown list in the Properties - Tables panel, Table:Coefficients contains the lift, drag, and moment coefficients. Moments are typically calculated in the , therefore, body-fixed axes moments, in addition to the lift and drag coefficients, which are coefficients, have been added to the default table. The body-fixed coefficients have been distinguished from the wind-fixed axes coefficients by the use of gray color. The final three columns show convergence data for the lift and drag coefficients, as well as the maximum convergence of the three moment coefficients.

Fluent Aero currently supports the body-fixed and wind-fixed coordinate systems for displaying aerodynamic forces, moments, and coefficients. Display Aero Forces in the Properties - Tables panel allows you to display the forces and moments, as well as their coefficients, in the body-fixed, wind-fixed, or both coordinate systems at the same time. The images below demonstrate these options using the aerodynamic coefficients from this tutorial.

When is selected from Display Aero Forces in the Properties - Tables panel, Table:Forces contains the lift and drag forces, as well as the moment, as shown in Figure 2.37: Results Table of the Aerodynamic Forces when Default Is Selected. The gray color is used to differentiate between data from body-fixed axes and data from wind-fixed axes. Similar to Table:Coefficients, you can select from the same dropdown list to display forces and moments in either the body-fixed, wind-fixed, or both coordinate systems.

Note: When you right-click Tables in the Outline View and select , the displayed tables of forces and moments, along with their coefficients, will be written to Table-Coefficients.csv and Table-Forces.csv.

Table:Residuals summarizes the final residuals as well as the number of iterations run for each design point.

Table:Custom Outputs shows the final values of the custom outputs.

Click Graphs in the Outline View to show the plots of the aerodynamic coefficients defined in Fluent Aero. At the bottom of the Properties - Graphs window, click Plot Coefficients. An X-Y plot of lift coefficient () vs. design point (DP) will appear in the Graphics window. The drag and moment coefficients can be shown by selecting and from the Curve selection drop-down list.

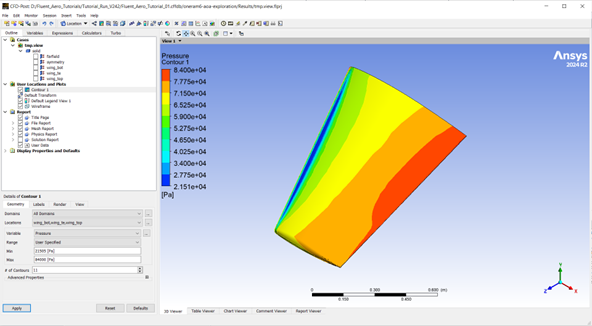

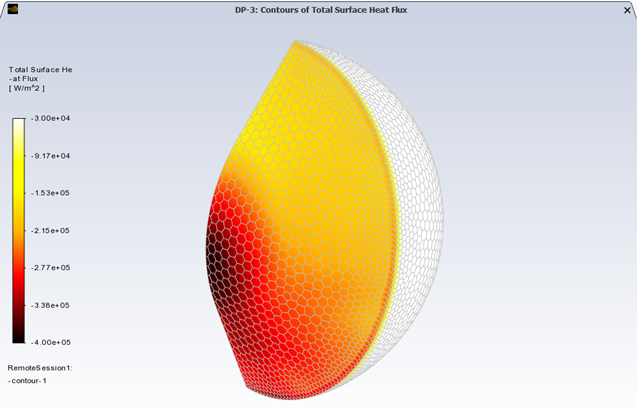

You will now go to the Design Point (DP-# Loaded) section and visualize graphics results such as contours for a specific design point in the graphics window. After creating these graphics objects, you can easily re-use them for remaining design points. You will first analyze the graphics results for design point 3. From the Properties – Design Point (DP-# Loaded) panel.

Click command to load the solution file of design point 3.

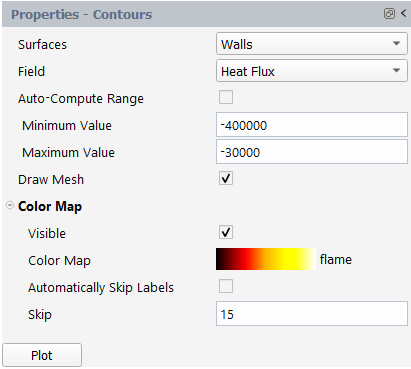

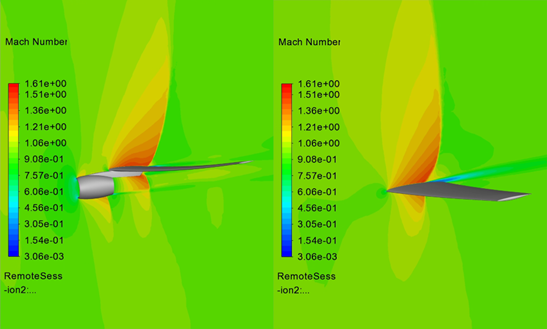

Select Contours under Graphics. There are two methods to create a contour. One way is to right-click on Contours, select and then specify the contour properties. Alternatively, you can predefine the properties from the Properties - Contours panel before creating the contour:

Set Surfaces to .

Set Field to .

Uncheck to disable .

Set the Minimum and Maximum Value to

-400000and-30000respectively.Check to enable .

Click to expand Color Map.

Change Color Map to flame.

Uncheck and set Skip to

15.Click to create and display the contour in the Graphics window. A contour-1 node now appears under Contours.

In the Graphics window, use the mouse to set the view of the contour. Right-click on contour-1 and then select . This will save the current view as aero-view-contour-1 under the View option in the properties panel of contour-1.

Note: To change the graphics display settings, you can go to File → → . For example, in the Lighting section, you can set Headlight to , and set appropriate values to both Headlight intensity and Ambient light intensity to personalize the graphics object rendering.

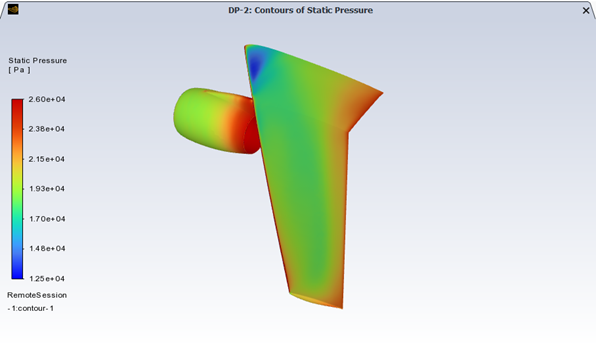

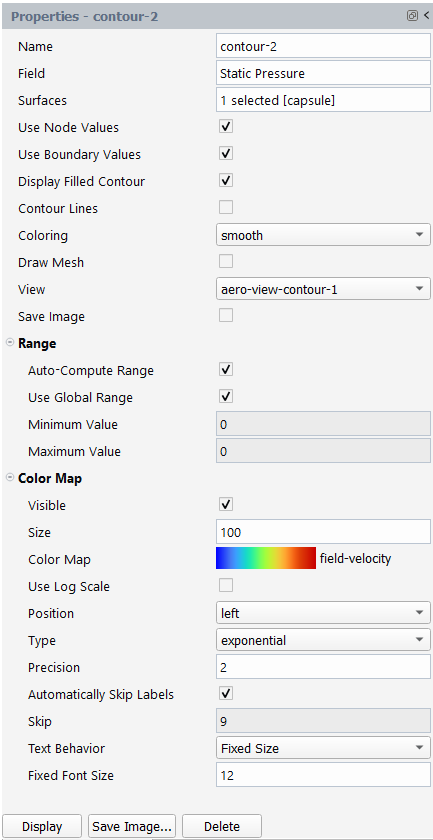

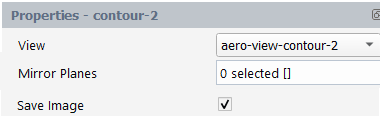

You will now create a contour of static pressure on wall surfaces. Right-click on Contours, select . A contour-2 node now appears under Contours. Go to the Properties – contour-2 panel:

Set Field to .

Set Surfaces to capsule.

Set View to .

Set Color Map to .

For the remaining settings, keep the default options.

Click .

In this solution, notice the high pressure region around the stagnation point located towards the front of the capsule (left side in image), and the low pressure region in the backside of the capsule, which is surrounded by the wake.

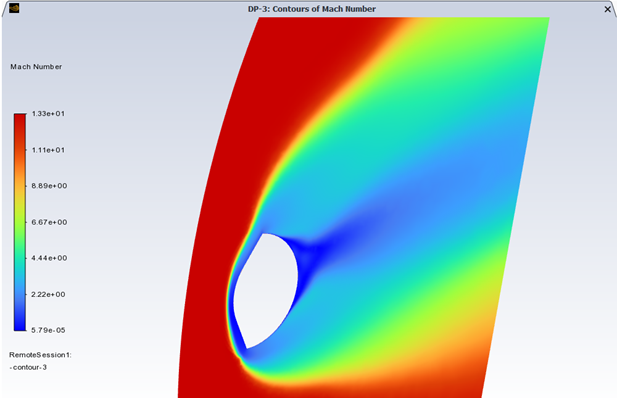

Click on Contours in the Outline View. In the Properties - Contours area, set Surfaces to , Cutting Plane Normal Direction to , Cutting Plane Position [m] to

0.1and Field to Mach Number. Enable . Disable , set Color Map to . Click the button to show the cutting plane contour in the Graphics window.Navigate to Design Point (DP-3 Loaded) → Plots. The Plots options can be used to quickly display simple 2D plots of selected design points and solution variables. The Properties - Plots window will be displayed.

Set Surfaces to .

Set Surface Cut Normal Direction to .

Set Surface Cut Position [m] to

0.1.Set Field to .

Click .

Since the solution for DP-3 at Z=0.1m will be plotted in the Plots window, a cut plot using default plot options will be created and a popup panel which allows you to customize certain plot options will appear. If the field is set to , the option for the y-axis will be enabled.

From the Plot Options panel, set the Pattern to in Curve Settings. Click . The 2D cut plot in the Graphics window will be updated using these new settings.

After generating all the graphics objects for design point 3, you can load a different design point and re-use these graphics objects. You also have the option to save the images of the graphics objects you created for the current design point or for all the updated design points.

Navigate to the properties panel of the graphics objects that you want to save the image and activate the flag.

You can also click on the button from the properties panel and customize the settings for saving your image. Click to save these settings.

To save all graphics objects with the Save Image flag enabled for DP-3, click from the Properties – Design Point (DP-3 Loaded) panel. Fluent Aero will iterate over all the graphics objects with the Save Image flag activated and save the images in the Results folder.

To display the graphics objects for a different design point, change Design Point To Load to that design point and click .

If you want to save images that have the option enabled for all the updated design points, click . The settings from the properties panel, including the specified view and save image options will be applied.

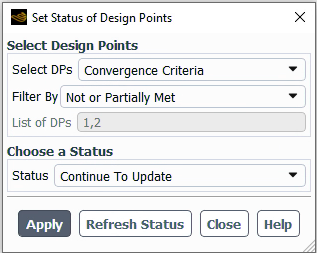

To further improve the convergence, you can continue to calculate the design points from the current results.

Go to the Input:Design Points table. Set the Status of design points that have not fully met the convergence criteria to . This operation can also be performed by using commands in the Design Points ribbon.

Click Design Points in the top ribbon.

Click Status → .

A Set Status of Design Points dialog opens which can be used to set the status of a group of design points.

Set Select DPs to .

Set Filter By to .

Set Choose a Status → Status to .

Click .

The status of all the design points will be set to .

In the Outline View, under Solution → Solve, set the Iterations to

250and click .Note: Other commands available in the Design Points ribbon can be useful to manage your calculation activities. For example, an alternative option to perform the procedure outlined above would be to use the Solve → command. This allows you to update a group of design points without needing to set their status. If you select and then select , all design points that have not met their convergence criteria will immediately .

Notice that after completing a calculation, the convergence of residuals have improved and the Conv. Criteria Met? of some design points might now be set to in Table:Summary.

Note: In the above tutorial, Fluent Aero’s default solver convergence settings are used to calculate the first 1500 iterations of each design point. However, in some cases, it is possible to start the calculation with different solver settings in order to improve convergence.

For example, you could repeat the above tutorial using more aggressive solver settings by performing the steps below.

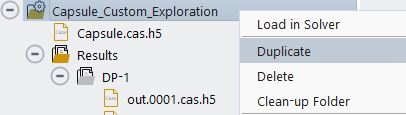

Create a simulation, set up the Geometric Properties, Airflow Physics and Simulation Conditions as previously described in the above steps. Alternatively, you can duplicate the previous simulation, including all setups, by right-clicking the Capsule_Custom_Exploration project folder located in the Outline View and selecting . You only need to change the solver settings.

In the Outline View, go to Solution → Solve. In the Properties - Solve panel, enter the following alternate settings:

Set the Iterations to

1500.Set Convergence Settings to . This will reveal additional options that can be useful to modify to attempt to improve the convergence or the speed of convergence.

Set the Convergence Criteria to . This will reveal the convergence cutoff values for residuals and aero coefficients, which can be modified to either improve or relax the convergence. Change the Flow Range from to . This will reveal solution steering settings.

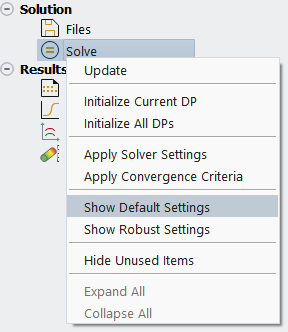

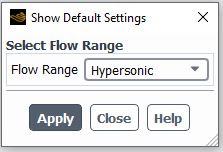

Right-click Solve from the Outline View and select the command.

From the Show Default Settings panel, change Flow Range to and press . This will show the Convergence Settings set as that have been previously applied in the first part of this tutorial inside the Properties - Solve panel.

Increase the Initial Courant Number from

1to4.

Press to launch the calculation. With these more aggressive settings, the calculations will converge faster.

After completing the current simulation, you can close the solver by right-clicking Capsule_Custom_Exploration from the Outline View and selecting . An information panel will appear to ask you if you want to save the case file or not. Click to save the case file and preserve all the post-processing graphics settings.

Close the project and exit Fluent Aero. From the ribbon, select Project → to close a project. Next, select → and the Fluent Aero workspace will be closed.

Part II – Earth Re-Entry Simulation at High Altitudes

In this section, you will simulate a re-entry mission at high altitudes where flight conditions of a design point are in the transitional flow regime of rarefied gases. To enhance the accuracy of simulations at these conditions, an 11-species air mixture is used to account for ionization.

Open the project created in Part I – Earth Re-Entry Simulation.

In the Project ribbon, select Simulations → and browse to and select the Capsule.msh.h5 file. A New Simulation window will appear. Enter the Name of the New Simulation as

High_Altitude_ReEntryand check .Set the Geometry Properties as in Part I – Earth Re-Entry Simulation.

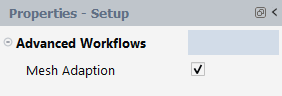

In the Setup tree, go to Airflow Physics. A Properties – Airflow Physics window appears below the Outline View window. Go to the → → Aero and enable . This will reveal the Transitional Regime Threshold above which the transitional regime for rarefied gases starts.

In the Solver section:

Set Type to .

In the Models section:

Set Viscous to .

Set Corner Flow Correction to Disabled

Set Curvature Correction to Enabled

Set Reactions to . When enabled, you will be able to use a mixture representation of Earth's atmosphere in Materials and the Two Temperature model will be automatically set to .

Note: Additional feature license is required to enable the use of this model. Contact your Ansys representative to check for the availability of the license increment.

Set Knudsen Number Criterion to .

Set Transitional Regime Threshold to

0.01.

In the Materials section:

Set Air Properties to .

Set Mass Fractions to

[0, 0.233, 0, 0, 0, 0, 0, 0, 0, 0, 0.767]by clicking the button located on the right-hand side of the mass fractions display box. Set the species fractions within the panel that appears.

In the Setup tree, select Simulation Conditions. A Properties – Simulation Conditions window appears below the Outline View window.

Enter the Mach Number and Altitude [m] cells from DP-1 and DP-2 into the table, as shown in Figure 2.46: Input:Design Points Table of a Custom Exploration With 2 Design Points. When you enter the conditions for DP-2, a Knudsen Number column appears automatically because its Knudsen number is greater than the default threshold of 0.01 for the rarefied gas transitional flow regime. The orange color indicates that the Knudsen Number Criterion in Airflow Physics will be used for DP-2.

Keep the default settings in the Component Groups section.

Go to Solution → Files in the Outline View.

Keep the default settings.

Select Solve.

Set Convergence Settings to . Iterations automatically sets to

2000.Keep Convergence Criteria to .

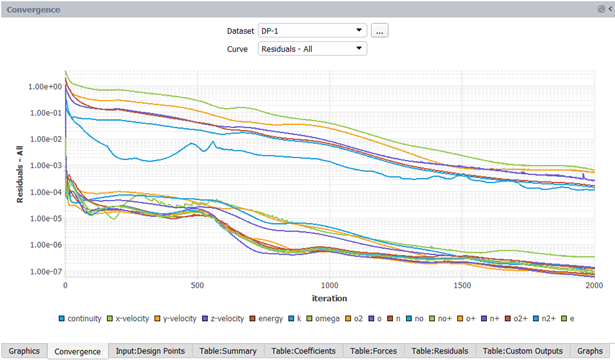

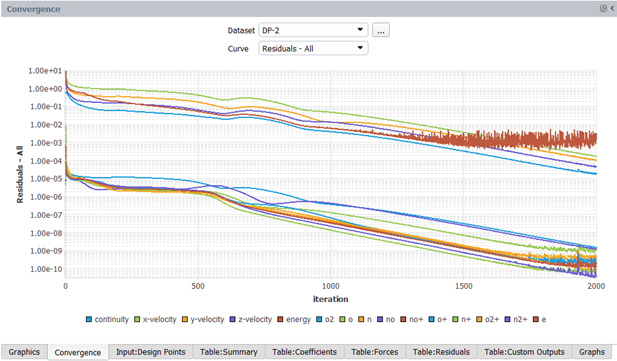

Click the button. The simulation will begin with DP-1 and then progress to DP-2 once completed. The DP-1 residuals plot will appear in the Convergence window on the right side of the screen.

The convergence curves of the and groups will now be combined. In the Convergence window, select → → . You can now select and add curves to Curve → .

In the Add curve dialog, select under Add curve to plot and press . This will add all the species residuals under to .

In the New curve dialog, under New curve name as

Residuals – Alland press .

Set Dataset to in the Convergence window and repeat the steps to create the combined residuals plot for .

In the Convergence window, set Dataset to and Curve to . Select → → . This allows you to select a file and append its data to the current curves.

In the Open File dialog, navigate to and select out.0001.fconverg in the Results folder of the current simulation. On the second panel that appears, enter DP-1 as Tag for the new dataset.

You can now use the → → to combine the history of the drag coefficient from these two design points in the same plot.

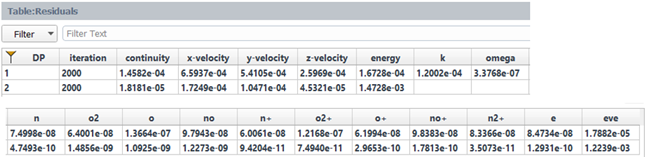

In the Graphics window area, select Table:Summary where flight conditions and convergence information can be found. You can see from the convergence curves that the convergence of lift and drag plateaued. However, you may notice in the final column of this table that both design points have not fully met the default residuals convergence criteria of 1e-5. You could relax the convergence criteria by increasing the values of Residuals Convergence Cutoff to have the Conv. Criteria Met? column set to or run the calculations for more iterations until the default convergence criteria is met.

Select Table:Residuals to verify the final residuals as well as number of iterations run for each design point. Notice that the columns of k and omega are empty for DP-2 since laminar flow was imposed by the Knudsen Number Criterion.

The Results node in the Outline View allows you to quickly post-process results by obtaining aerodynamic coefficient plots, creating contour plots of solution fields, comparing solution fields to experimental data, and more. For more information, refer to Part I – Earth Re-Entry Simulation. In this section, you will only generate contour plots of Mach number and molar concentration of electron. Go to Results → Design Point (DP-# Loaded). From the properties panel, set Design Point to Load to

2and click the button.

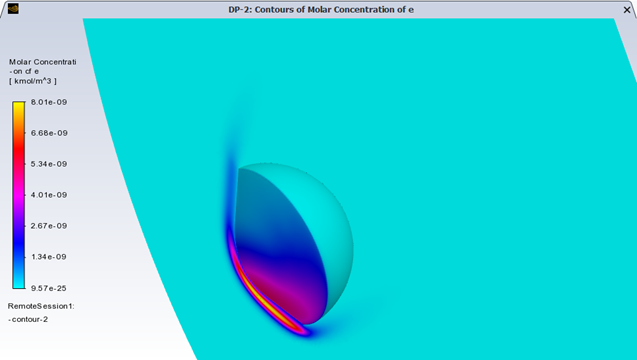

Left-click Contours from the Outline View to display the Properties – Contours window.

Set Surfaces to .

Set Selected Surfaces to sym and capsule.

Set Field to .

In the Color Map section:

Set Color Map to .

Uncheck and set Skip to

15.Click the button and adjust your view within the Graphics window.

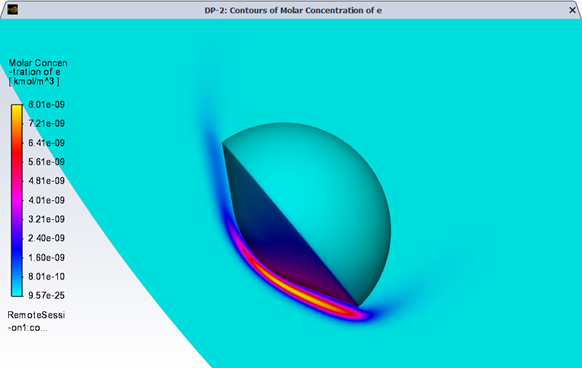

In the Properties – Contours panel, change only Field to . Click the button. Contours of the electron molar concentration will be displayed. The electron concentration is in the area behind the shock and the maximum electron molar density is 8.01e-9 kmol/m3, which is about 4.82e18 of electrons per cubic meter.

After completing the current simulation, you can close the solver by right-clicking High_Altitude_ReEntry from the Outline View and selecting . An Information dialog box will appear asking you to save the case file, click to save the case file and preserve all the post-processing graphics settings.

Part III – Modeling the Flow Around an Entry Capsule in Martian Atmosphere

In this section, you will simulate a Mars entry condition based on the flight path of the Viking lander mission 2 using the same capsule geometry as in Part I – Earth Re-Entry Simulation. In this case, to improve accuracy of simulations, the air mixture of the Martian atmosphere is used.

Open the project created in Part I – Earth Re-Entry Simulation.

In the Project’s ribbon, select Simulations → New Aero Workflow, and browse to and select the Capsule.msh.h5 file. A New Simulation window will appear. Enter the Name of the New Simulation as

Mars_Entry_Mission, and check .Set the Geometry Properties as in Part I – Earth Re-Entry Simulation.

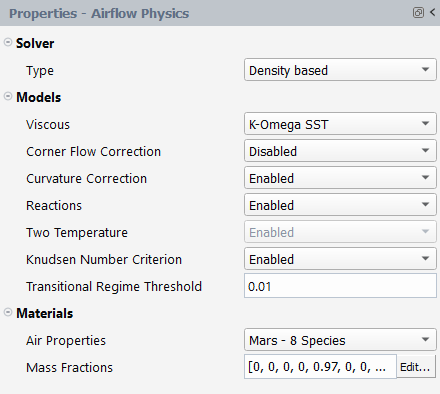

In the Setup tree, go to Airflow Physics. A Properties – Airflow Physics window appears below the Outline View window. Go to the → → Aero and enable . This will reveal the Transitional Regime Threshold above which the transitional regime for rarefied gases starts.

In the Solver section:

Set Type to .

In the Models section:

Set Viscous to .

Set Corner Flow Correction to .

Set Curvature Correction to .

Set Reactions to . When enabled, you will be able to use a mixture representation of the Martian atmosphere in Materials and the Two Temperature model will be automatically set to .

Note: Additional feature license is required to enable the use of this model. Contact your Ansys representative to check for the availability of the license increment.

Set Knudsen Number Criterion to .

Set Transitional Regime Threshold to

0.01.

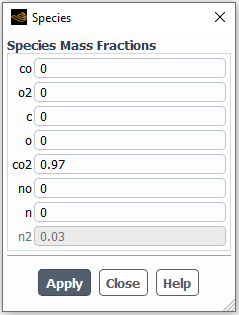

In the Materials section:

Set Air Properties to .

Set Mass Fractions to

[0, 0, 0, 0, 0.97, 0, 0, 0.03]by clicking the button located on the right-hand side of the mass fractions display box. Set the species fractions within the panel that appears.

In the Setup tree, select Simulation Conditions. A Properties – Simulation Conditions window appears below the Outline View window.

Set the Number of Design Points to

1.In the Flow Speed section:

Set Parameter to .

Set Distribution to .

Set True Airspeed [m/s] to

4563.1.

In the Flow Direction section:

Set Parameter to .

Set Distribution: Angle of Attack to .

Set Angle of Attack [deg] to

18.4.

In the Pressure and Temperature section:

Set Parameter to .

Set Distribution to .

Set Flight Altitude [m] to

47419. The Atmospheric Static Pressure [Pa] and Atmospheric Static Temperature [K] will be automatically computed based on the analytical altitude profiles created from the Viking lander re-entry profiles.

In the Turbulence section:

Set Parameter to .

Set both Distribution: Turbulent Intensity and Turbulent Viscosity to .

Set Turbulent Intensity [%] to

0.08.Set Turbulent Viscosity Ratio to

1e-5.

In the Wall Conditions section:

Enable .

In the Thermal Conditions section:

Set Parameter to .

Set Distribution to .

Set Temperature [K] to

2000.

After setting the Simulation Conditions, Fluent Aero automatically calculates the Knudsen number (Kn). If any design point has a Knudsen number above the threshold of the transitional flow regime of rarefied gases, it will automatically be displayed in the input table. You can also manually show Knudsen number by right-clicking Simulation Conditions and selecting the . The Knudsen number of the current simulation is grayed out, indicating it is below the default threshold of 0.01 for the transitional regime. Consequently, the Knudsen Number Criterion that imposes laminar flow and partial slip wall conditions will not be applied to the current design point.

Keep the default Component Groups settings.

Go to Solution → Files in the Outline View.

Keep the default settings.

Select Solve.

Set Iterations to

1000.Keep Convergence Settings and Convergence Criteria to .

Click the button located at the bottom of the Properties - Solve panel. The simulation will first initialize using the flight conditions of DP-1 and then DP-1 will begin to iterate. The residuals plot of DP-1 will appear in the Convergence window located on the right of the screen.

In the Convergence window, set Dataset to and Curve to . The evolution of the drag coefficient for DP-1 will be displayed. You can query the value of the drag coefficient by left-clicking the curve.

Go to the Graphics window area and select Table:Summary where flight conditions and convergence information can be found. You can see from the convergence curves that the convergence of lift and drag plateaued. However, you may notice in the final column of this table that DP-1 has not fully met the default residuals convergence criteria of 1e-5. You could relax the convergence criteria by increasing the values of Residuals Convergence Cutoff to have the Conv. Criteria Met? column set to or calculate for more iterations until the default convergence criteria is met.

The Results node in the Outline View allows you to quickly post-process results by obtaining aerodynamic coefficient plots, creating contour plots of solution fields, comparing solution fields to experimental data, and more. For more information, refer to Part I – Earth Re-Entry Simulation.

You will generate a contour plot of the CO2 mass fraction below. Left-click Contours from the Outline View to display the Properties – Contours window.

Set Surfaces to .

Set and as Selected Surfaces.

Set Field to .

Click to expand Color Map.

Set Color Map to .

Uncheck and set Skip to

15.Click the button. From the Graphics window, adjust the view.

After completing the current simulation, you can close the solver by right-clicking Mars_Entry_Mission from the Outline View and selecting . An Information dialog box will appear asking you to save the case file, click to save the case and preserve all the post-processing graphics settings.

Close the project and exit Fluent Aero by selecting Project → Close followed by → to close the Fluent Aero workspace.

Part IV – Ionized Data Conversion to HFSS

In this section, you will build upon the simulation completed in Part II – Earth Re-Entry Simulation at High Altitudes – by utilizing ionized data conversion to HFSS as part of the workflow for Part IV – Ionized Data Conversion to HFSS. The Earth Re-Entry Capsule discussed in Part II – Earth Re-Entry Simulation at High Altitudes considers the Air – 11 Species (Park) model, which includes electrons, and is conducted around the rarefied gas flow regime. Before proceeding, you are encouraged to review Export Ionized Data to HFSS in the Fluent Workspaces User's Guide for more details. The Input:Design Points table below outlines the primary parameters and properties of the loaded simulation.

Note: The Knudsen Number for DP 2 is highlighted in orange, indicating that the flow regime for this design point is in the rarefied gas flow regime.

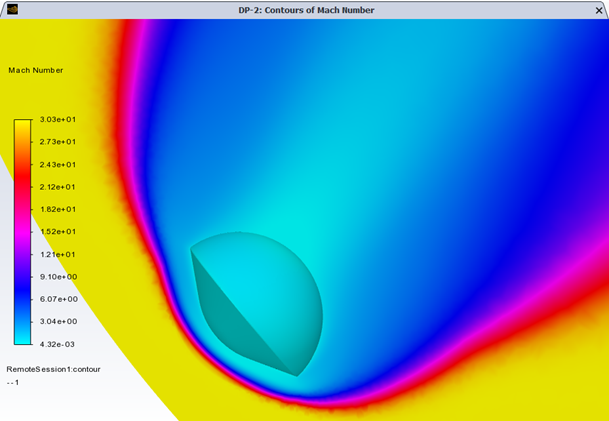

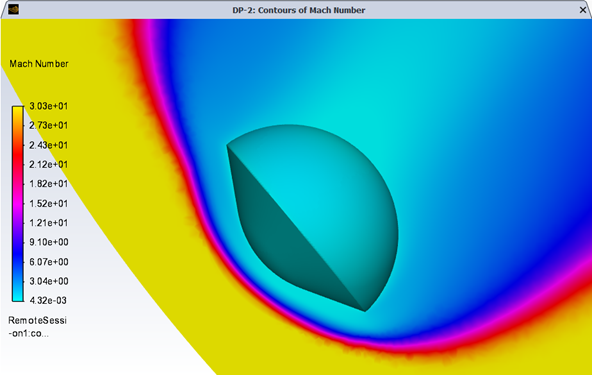

The figures below provide a graphical representation of the results for DP 2 on the symmetric plane and the capsule surface:

Figure 2.54: Contour of Mach Number illustrates the variation in Mach number across the flow field around the capsule, highlighting areas of compression, shock waves, and wake regions.

Figure 2.55: Contour of Molar Concentration of Electrons of e shows the distribution of electron molar concentration within the rarefied flow, offering insights into ionization and chemical reaction zones near the capsule.

These visualizations complement the tabular data and highlight the role of the rarefied gas dynamics in influencing the flow behavior around the capsule during re-entry. To begin the extraction of the ionized data, follow the steps below:

Open the project Fluent_Aero_Tutorial_HFSS.flprj project file located in fluent_aero_tutorial.zip.

In the Project View, right-click Capsule_Part_II_Earth_High_Alt_ReEntry and select .

Project View → Capsule_Part_II_Earth_High_Alt_ReEntry

Load in Solver

Since the loaded simulation contains already the ionized flow results, you can directly use the ionized data converter. Navigate to the top ribbon and select

Results → Export to HFSS → Export Ionized Data....

Note: To use this tool, an additional feature license is required. Please contact your Ansys representative to verify the availability of the license increment. Moreover, electrons should be present inside the Fluent Aero solution to capture and extract an ionized zone for HFSS and only one species mixture is supported for all design points. This species mixture corresponds to the current mixture of the Fluent Aero simulation. If electrons are not present in your solution, you will not be able to execute this tool.

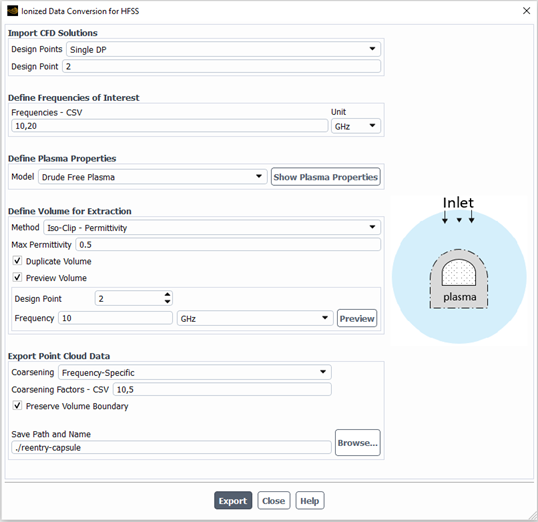

An Ionized Data Conversion for HFSS dialog will appear, allowing you to define settings for converting ionized data.

In the Import CFD Solutions section, you will specify the design point solution for extraction:

Set Design Points to .

Set Design Point to

2.

In the Define Plasma Properties section, you will enter the radio frequencies of interest:

Set Frequencies – CSV to

10,20and Unit to .

In the Define Plasma Properties section:

Set Model to .

Click to print the flow field plasma properties to the Console, including the range of permittivity and conductivity, for each specified DP and frequency.

In the Define Volume for Extraction section:

Set Method to .

Set Max Permittivity to

0.5.Enable .

Enable . This will reveal a new section where you can specify the design point and frequency to preview the plasma volume.

Set Design Point to

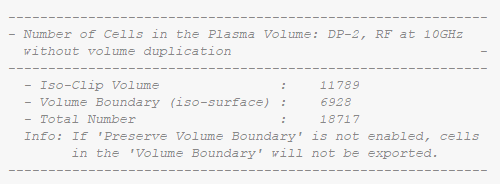

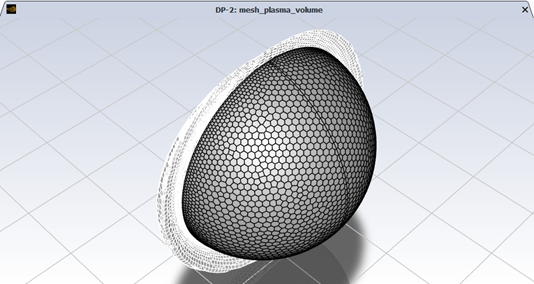

2.Set Frequency to

10GHz.Click . The number of cells that will be extracted from the mesh before duplication is printed in the console and the boundary of the plasma volume will be displayed in the Graphics window.

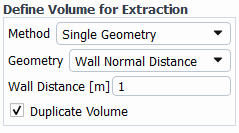

Note: Alternatively, the plasma volume can be created using simple geometries by following these steps:

Set Method to . When is selected, you can choose one of the following options to extract the sub-domain of interest:

: Extracts the volume within a specified distance of the wall surfaces.

: Allows you to define a sphere by providing the center coordinates and radius.

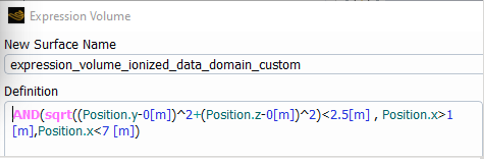

If is selected, you can manually create an Expression-Volume (for example, a cylinder) in the Fluent Solution workspace under Surfaces. Enter the Expression-Volume Name in this panel. The Fluent Aero software will automatically use it to extract the sub-domain.

The figure below shows an expression volume of a cylinder created in the Fluent Solution workspace.

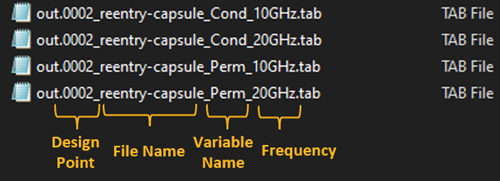

In the Export Point Cloud Data section:

Set Coarsening to .

Set Coarsening Factor - CSV to

10,5.Enable .

Set Save Path and Name to

./folder_path/reentry-capsule